0102030405

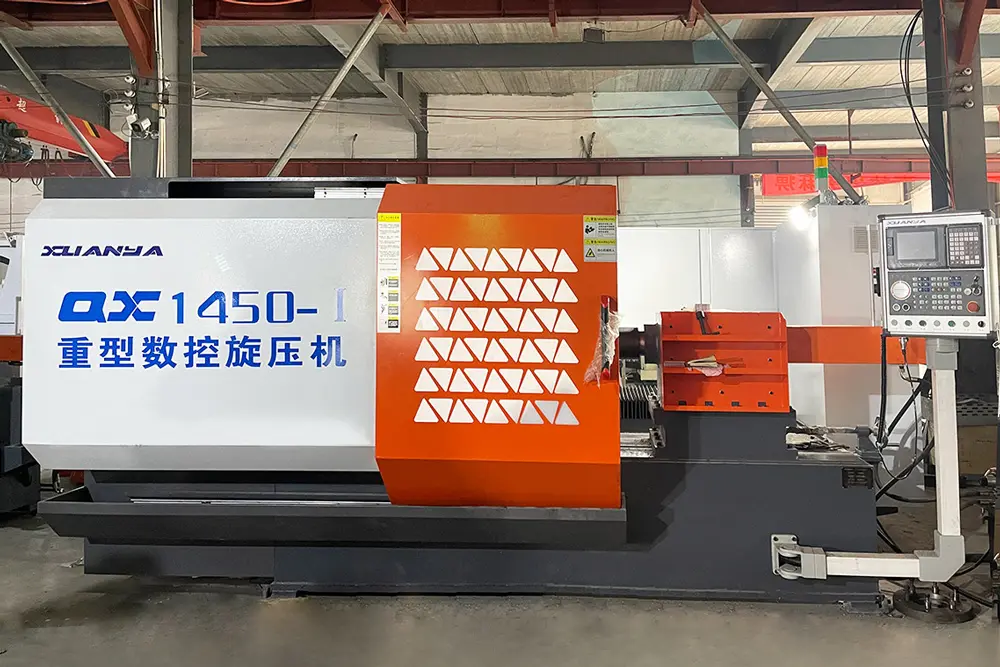

Automatic CNC Metal Spinning Machine For Manufacturing Funnels Lampshades And Conical Containers

Product Description

The standout features of the PX1000 is its versatile range of processing technology options. This allows users to customize the machine's capabilities to suit a wide array of part shapes and specifications. Such flexibility is particularly beneficial in industries that demand high precision and diverse processing methods. The PX1000 can be easily adjusted to accommodate different shapes, sizes, and material types, making it an invaluable tool for manufacturers.

In addition to its proficiency in processing long cylinders and deep containers, the PX1000 boasts powerful overall processing capabilities, making it suitable for a broad spectrum of applications. This includes industries such as kitchenware manufacturing, where it is used to produce large cooking pots and pans; the musical instrument sector, where precision and attention to detail are paramount; the automotive industry, particularly for crafting engine components and accessories; and even the aerospace sector, where intricate and detailed processing is essential.

Furthermore, the machine’s versatility allows users to select from a variety of processing options tailored to their specific production needs. This adaptability not only optimizes production efficiency but also minimizes downtime, ensuring that each workpiece meets the highest quality standards. Whether working on small batches or engaging in large-scale production runs, the PX1000 is engineered to deliver exceptional results across a wide range of industries. Its combination of spacious processing capabilities, flexibility, and precision makes it a top choice for manufacturers looking to enhance their production processes.

Product parameters

|

Item |

Parameter |

||

|

Model |

PX1000-Ⅰ |

QX1000-Ⅱ |

|

|

Maximum sheet diameter |

1000mm |

||

|

Diameter of over-drag plate |

700mm |

||

|

Main motor power |

18.5kw |

||

|

Spindle speed |

1500Rpm |

||

|

Stroke |

X-axis |

1000mm |

|

|

Z-axis |

600mm |

||

|

Maximum tail force |

15kn |

||

|

Tail stroke |

500mm |

||

|

Processing material thickness |

Copper/aluminum |

0.5-5.0mm |

|

|

Steel |

0.5-3.0mm |

||

|

Stainless steel |

0.5-2.5mm |

||

|

Tool holder station |

4/6/8 |

||

|

Whip blank support plate travel |

300mm |

||

|

Positioning accuracy |

0.02mm |

||