Leave Your Message

Accurate Metal Spinning is a highly specialized manufacturing process that allows for the creation of intricate metal components through the precise manipulation of metal sheets over a mandrel. This technique has gained significant traction in various industries, including aerospace, automotive, and industrial manufacturing, due to its remarkable efficiency and versatility. According to a recent report from the Metal Forming Association, the metal spinning market is projected to grow by approximately 6% annually through 2025. This growth is largely attributed to the increasing demand for lightweight, durable components and their applications in cutting-edge technologies.

One of the key advantages of Accurate Metal Spinning is its ability to reduce material waste while maintaining high levels of accuracy. This is critical in industries where precision is paramount. The process enables manufacturers to produce complex geometries with minimal setup time and cost, offering a competitive edge in a rapidly evolving market. Furthermore, a study conducted by the Manufacturing Institute indicates that companies utilizing advanced manufacturing techniques, including metal spinning, are poised to enhance their productivity by upwards of 20%, thereby achieving substantial economic benefits.

As organizations strive for innovation and sustainability in their production methods, Accurate Metal Spinning emerges as a vital solution that meets both operational efficiency and environmental considerations. With its numerous benefits, this technique not only streamlines production processes but also supports the overarching goal of producing high-quality products that cater to the evolving needs of consumers and industries alike.

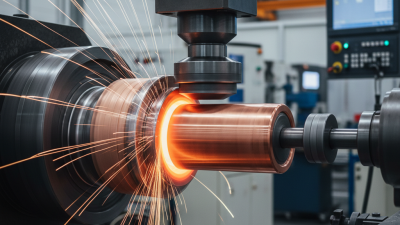

Accurate metal spinning is a precision manufacturing process that allows for the creation of complex shapes from metal sheets. The fundamental principle revolves around the rotation of the metal while being shaped by a tool, resulting in high symmetry and uniformity. This technique can accommodate various materials, including aluminum, steel, and brass, making it versatile for numerous applications in different industries.

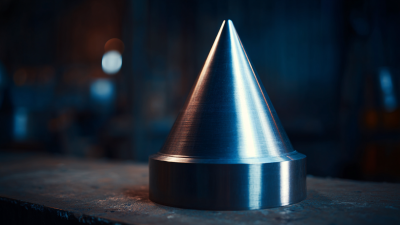

One of the primary benefits of accurate metal spinning is its ability to produce components with minimal waste, as the process uses the entirety of the starting material. Additionally, the quality and strength of the spun parts are often superior to those produced by other methods, thanks to the uniform thickness achieved during spinning. This ability to maintain structural integrity while creating intricate designs makes accurate metal spinning an invaluable technique for manufacturing projects that demand both precision and efficiency.

| Attribute | Description | Benefits |

|---|---|---|

| Precision | Accurate metal spinning allows for the creation of highly precise and complex shapes. | Improved fit and function of components, reducing the need for additional machining. |

| Material Versatility | Can be used with a variety of materials including aluminum, copper, and stainless steel. | Flexibility in design options to meet specific project requirements. |

| Cost-Effectiveness | Lower material waste compared to other manufacturing processes. | Reduced production costs and better resource utilization. |

| Quick Turnaround | Production processes are generally faster than traditional machining methods. | Faster time-to-market for products, saving valuable project time. |

| Strength and Durability | Components produced are often stronger due to the work-hardening of the material. | Enhanced product longevity and reliability under stress. |

Accurate metal spinning is a versatile manufacturing process that offers numerous benefits for various projects. One of the key advantages of using accurate metal spinning is its ability to produce complex shapes with high precision, thereby minimizing material waste. According to the Metal Forming Technologies report, manufacturers can achieve up to 30% material savings compared to traditional machining methods when employing metal spinning techniques. This is particularly beneficial for industries like aerospace and automotive, where precision and material efficiency are paramount.

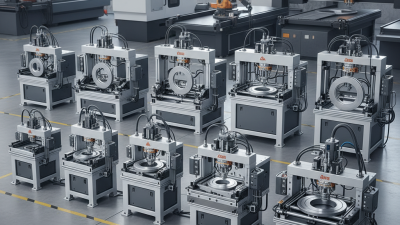

Another significant advantage is the rapid production time associated with metal spinning. With setups often completed in a fraction of the time required for other methods, projects can move from concept to production faster. The efficiency gained can lead to reduced overall costs, with some studies indicating that companies can decrease lead times by as much as 50%. This swiftness in production not only enhances responsiveness to market demands but also encourages innovation in design.

Tips: When considering accurate metal spinning for your project, ensure that your design is optimized for this technique to capitalize on its strengths. Additionally, collaborating with experienced manufacturers can greatly enhance the quality and efficiency of the final product. Lastly, always request samples or prototypes to validate the process before proceeding with full-scale production.

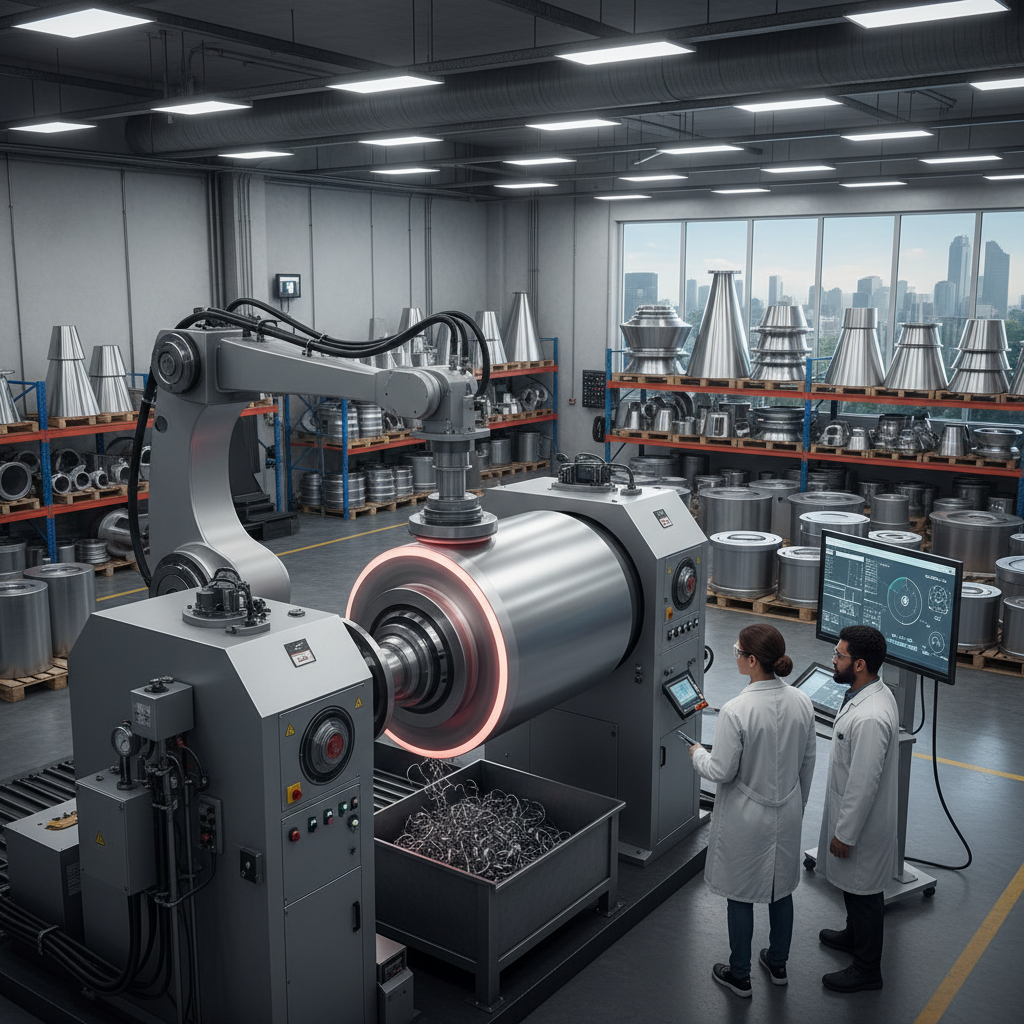

Accurate metal spinning is a versatile manufacturing process that finds applications across various industries due to its ability to create high-quality components with precision. In the aerospace sector, for instance, metal spinning is utilized to produce lightweight yet robust parts such as fuselage sections and engine components. The technique allows for intricate designs and minimizes material wastage, which is crucial in an industry where every ounce of weight counts.

Similarly, the automotive industry benefits significantly from accurate metal spinning. Components like wheel rims, housings, and exhaust systems are commonly produced using this method. The durability and strength of spun metal parts make them ideal for application in vehicles where performance and safety are paramount. Beyond aerospace and automotive, sectors such as medical devices, energy, and consumer products also leverage accurate metal spinning for custom components, showcasing its broad relevance in today’s manufacturing landscape.

Accurate metal spinning is a manufacturing process that allows for high precision and efficiency in creating cylindrical parts from metal sheets. According to a report by Technavio, the global metal spinning market is projected to grow by 5% annually, highlighting its increasing demand in various industries, including aerospace and automotive. This technique involves rotating a metal disc and shaping it against a form, ensuring that the final product maintains tight tolerances that are often critical for component functionality and overall project success.

One of the significant advantages of accurate metal spinning is its capability to reduce waste while enhancing productivity. Research indicates that metal spinning can utilize up to 70% of the raw material compared to traditional machining methods, where scrap rates can reach as high as 30%. This not only leads to cost savings but also promotes sustainability within manufacturing processes. Furthermore, the quick setup times associated with metal spinning allow for faster production cycles, which can lead to a 20% increase in production efficiency. As industries continue to seek ways to optimize manufacturing practices, accurate metal spinning stands out as a viable solution for achieving higher precision and efficiency in projects.

Accurate metal spinning offers distinct advantages over traditional shaping methods such as machining, casting, and stamping. One key difference lies in the precision and flexibility it allows in the manufacturing process. Unlike conventional machining, which often removes material to achieve the desired shape, metal spinning involves forming the metal around a rotating mandrel, thereby maintaining a higher material integrity. This process not only reduces waste but also allows for complex geometries that would be difficult or impossible to achieve through other methods.

Additionally, accurate metal spinning is highly advantageous for small to medium production runs. While traditional methods may require extensive tooling and setup, resulting in higher initial costs, metal spinning can be executed with minimal setup changes. This flexibility reduces lead times and allows for rapid prototyping and adjustment, making it a preferred choice for industries needing quick turnaround on custom components. The ability to achieve tight tolerances also enhances quality control, giving manufacturers a reliable option for precision applications.