Leave Your Message

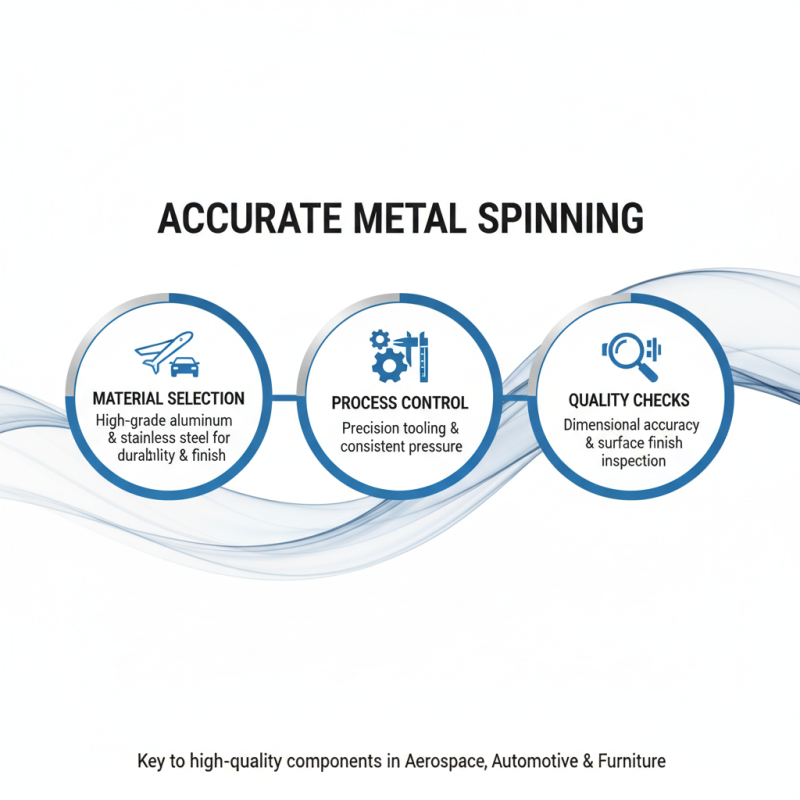

Accurate Metal Spinning is a highly specialized manufacturing process that transforms flat metal discs into precise and complex shapes through the application of mechanical forces. As industries demand higher-quality components with increased precision, mastering the techniques of metal spinning is crucial for manufacturers aiming to enhance their competitive edge. In this endeavor, understanding the fundamentals of Accurate Metal Spinning not only contributes to improved production efficiency but also significantly elevates the standard of the final products.

This article explores the essential methodologies and best practices that can lead to high-quality results in metal spinning. By delving into the key factors that influence accuracy—such as tool design, material selection, and equipment settings—we aim to equip manufacturers with the knowledge necessary to refine their processes. The pursuit of excellence in Accurate Metal Spinning is not merely about machinery but extends to the meticulous planning and skilled labor that drive successful outcomes in this craft. Through a comprehensive understanding of these elements, manufacturers can ensure that they consistently produce components that meet stringent quality requirements.

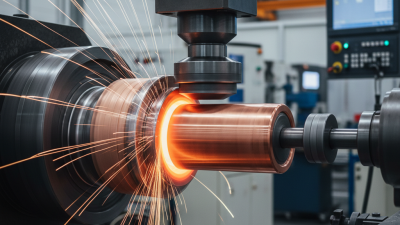

Metal spinning, a traditional manufacturing process, plays a crucial role in generating high-quality components with precise dimensions. This technique involves forming a flat metal disk into a symmetrical shape by rotating it at high speed against a mold. By controlling the speed and pressure applied, manufacturers can achieve intricate designs and maintain tight tolerances, essential for precision engineering applications. Understanding the fundamentals of metal spinning is key to improving production efficiency and ensuring product reliability.

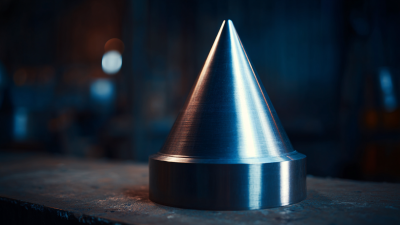

A major aspect of metal spinning is the selection of appropriate materials. Different metals offer unique characteristics that influence the final product’s quality. For example, materials such as aluminum and stainless steel are commonly used due to their favorable properties, including strength, ductility, and corrosion resistance. Knowledge of these materials allows manufacturers to tailor their processes for optimal results, achieving desired thickness and finish. Furthermore, familiarity with tooling and machine settings is necessary to refine the spinning process, ensuring accuracy and consistency in each batch produced.

Achieving accurate metal spinning is crucial for producing high-quality components across various industries, including aerospace, automotive, and furniture manufacturing. To ensure precision, several key techniques must be employed throughout the spinning process. One significant technique is the meticulous selection of materials, as using high-grade metals can significantly enhance the durability and finish quality of the final product. According to a 2022 industry report from the International Journal of Manufacturing, materials like aluminum and stainless steel not only provide superior mechanical properties but also facilitate better handling during spinning.

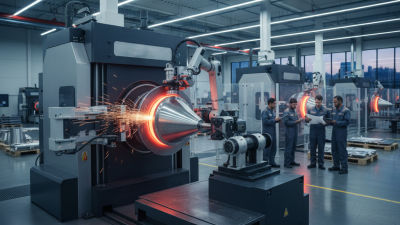

Another critical aspect of achieving precision in metal spinning is the optimization of tooling and equipment setup. The design and care of the tooling directly impact the accuracy of the finished product. Establishing proper tool geometry and using advanced CNC machines can lead to improved dimensional consistency. A recent survey conducted by the Society of Manufacturing Engineers revealed that manufacturers employing state-of-the-art equipment saw a 40% reduction in defects and waste during the metal spinning process. Implementing these advanced techniques, alongside continuous monitoring and adjustments throughout production, are essential for ensuring that high-quality results are achieved in metal spinning operations.

Achieving high-quality results in metal spinning relies heavily on the use of essential tools and equipment. The foundation of any successful metal spinning project starts with a reliable lathe, which provides the necessary rotational force to shape the metal accurately. A heavy-duty metal lathe equipped with appropriate speeds and torque settings is critical, allowing for fine adjustments that can accommodate various metal types and thicknesses. Additionally, incorporating a robust tool holder ensures stability and precision during the spinning process, reducing the risk of errors and enhancing the overall quality of the finished product.

Another vital aspect of quality metal spinning is the selection of the right tooling. High-quality spinning tools made from durable materials are crucial for achieving the desired design. These tools should be designed to efficiently manipulate the metal while minimizing wear and tear, ensuring longevity and consistent performance. Supporting equipment such as hydraulic presses or hand-held tools also play a significant role, as they help control the shaping process and provide the necessary force to form the metal accurately. Furthermore, investing in measuring and inspection tools, like calipers and gauges, to verify dimensions throughout the spinning process ensures the final product meets the required specifications, ultimately contributing to the overall quality and reliability of metal-spun items.

In the realm of metal spinning, maintaining high quality standards is paramount to achieving precise and reliable results. Key quality control measures must be integrated into the production process to ensure the final product meets desired specifications. First, implementing rigorous quality checks at various stages of production is essential. This includes pre-production inspections, in-process evaluations, and final product assessments, allowing for the early identification of discrepancies and enabling timely corrections.

Another critical aspect of quality control in metal spinning involves utilizing advanced technology and skilled personnel. The adoption of computer numerical control (CNC) equipment enhances accuracy and repeatability in forming processes, while experienced operators contribute to quality outcomes through their expertise in handling materials and tools. Furthermore, consistent training and skill development programs for staff ensure that they are well-versed in the latest techniques and quality standards, reinforcing the overall integrity of the finished products. By emphasizing these measures, manufacturers can achieve exceptional quality in their metal spinning operations, ultimately leading to greater customer satisfaction and competitive advantage in the market.

Metal spinning is a highly effective manufacturing technique, but it comes with its own set of challenges. One common issue faced during the process is achieving the desired material thickness. Variations can lead to weak spots in the final product. To combat this, operators must ensure uniform pressure distribution and monitor temperatures closely throughout the spinning process.

Additionally, maintaining a consistent rotational speed is crucial for achieving high-quality results. Fluctuations can result in uneven surfaces or deformation. Implementing precise control systems and regular equipment calibration can help mitigate these problems.

**Tips:** Regularly inspect tooling for wear and replace parts as necessary to maintain accuracy. Additionally, consider using advanced materials that provide better formability and consistency during the spinning process. By addressing these challenges proactively, manufacturers can significantly enhance the quality and durability of their metal spun products.