Leave Your Message

In the fast-evolving world of industrial applications, choosing the right machinery is crucial. The "Flange Flanging Machine" stands out as a vital player in this space. Industry expert, Dr. Alan Thompson, highlights its importance: "An efficient Flange Flanging Machine can significantly enhance production quality and speed." This sentiment echoes across various sectors where flanging operations are key.

Many businesses still grapple with outdated equipment that hinders their productivity. However, advancements in flanging technology are reshaping the landscape. The best models come equipped with state-of-the-art features that improve precision and reduce waste. Yet, not all companies realize the potential impact of upgrading their machines. Some resist change, fearing the investment may not pay off.

Attention to detail in machine selection can reduce downtime and costs. A modern Flange Flanging Machine substantially increases throughput. On the contrary, companies utilizing older machines often face inefficiencies. It’s essential for business leaders to reflect on their choices. Balancing cost with efficiency is not always straightforward. Investing in the correct machinery can provide a competitive edge in the long run.

Flanging machines play a crucial role in various industrial applications. These machines are responsible for shaping metal edges, enabling a better fit and tighter seals in manufacturing processes. In 2021, the global flanging machine market was valued at approximately $2.5 billion and is projected to grow by over 5% annually, showcasing their rising importance. This growth emphasizes the need to understand and optimize flanging operations.

The advantages of utilizing flanging machines include increased production efficiency and improved product quality. For instance, research indicates that properly flanged components can reduce assembly errors by 40%. However, despite these benefits, many industries still struggle with inefficient flanging processes. Issues like material wastage and inconsistent flange dimensions remain common. A study found that 30% of manufacturers experience discrepancies in flanging that lead to higher costs and delays.

Additionally, advancements in technology could address existing challenges. Automated flanging systems are gaining traction. However, introducing new tech can be met with resistance due to the fear of disruptions. Striking a balance between innovation and employee training is necessary to fully leverage these machines. As industries evolve, addressing these concerns becomes vital for maximizing the potential of flanging operations.

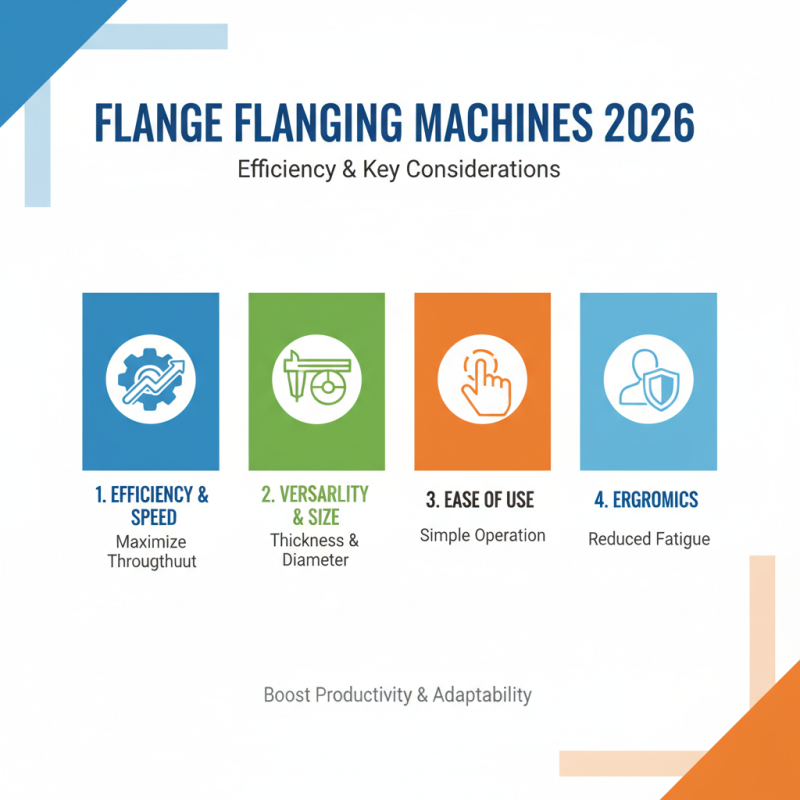

When looking for the best flange flanging machine in 2026, efficiency is key. Consider the machine's maximum flange thickness and size. A versatile machine adapts to different projects. Simple operation boosts productivity on the job. Ergonomic design plays a role in reducing operator fatigue, especially during long hours.

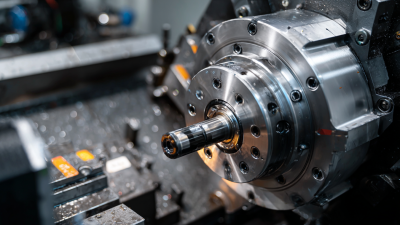

Look for features that enhance precision. Adjustable speed settings improve control over the flanging process. It’s essential to have a machine that offers consistent results. A clear user interface helps avoid confusion during operation. Maintenance should be easy and accessible. Regular checks on wear and tear are vital. Machines can fail if not properly cared for.

Also, think about portability. In some cases, workshops are small or crowded. A lightweight design makes transportation easier between job sites. However, ensure that sturdiness is not compromised. Some machines boast impressive features but lack durability. Striking a balance is crucial for long-term usage. Design choices should reflect real-world usage and adaptability.

In 2026, the demand for high-quality flange flanging machines continues to grow across various industries. These machines help create flanges with precision and consistency. The right equipment can significantly enhance productivity. However, not all machines are created equal. Users often find it challenging to choose the best option based on their specific needs.

When exploring available models, features like speed and ease of use become vital. Compact designs are becoming popular, especially in smaller workshops. But, larger industrial applications still require heavy-duty machines for bulk production. Many models now include digital interfaces. Yet, some users struggle with complex controls. A more intuitive design could improve user experience.

Selecting a flange machine often involves trial and error. Certain models may excel in durability but fall short on versatility. Maintenance is another aspect that cannot be overlooked. Some machines need frequent upkeep, which can hinder productivity. Ultimately, balancing efficiency, cost, and usability is the key to finding the right machine for your operations.

Flanging machines play a crucial role in various industrial applications. They shape metal sheets into flanges that ensure structural integrity and fit. A variety of technologies are available, each with its own advantages and setbacks. Users need to consider operational efficiency alongside overall machine performance.

In evaluating these machines, factors include speed, precision, and ease of operation. Some models may promise high production rates. However, they may lack the precision required for specific tasks. A machine that operates quickly might produce flawed flanges, leading to waste. Identifying a balance between speed and accuracy is essential.

One also must consider maintenance needs. Machines requiring frequent calibrations can lead to downtime. This may reduce overall productivity, overshadowing their initial efficiency claims. Investing in a machine is not just about upfront costs; it’s about long-term operational performance and reliability. Each choice has implications for the workflow, underscoring the importance of careful evaluation.

The future of flanging technology is evolving rapidly. Automation and advanced materials are now key components in flanging applications. Industries are seeking machines that are not only efficient but also adaptable to various materials. The shift toward smart technology allows for better monitoring and control. This leads to a reduction in waste and increased precision.

Mechanization in flanging processes can also introduce challenges. Operators may face a learning curve with new systems. The integration of AI for predictive maintenance is promising. However, it requires careful implementation. Many professionals are unsure how to best apply these technologies. The transition to automated processes must consider workforce training.

Environmental concerns play a significant role in future trends. Machines are becoming more energy-efficient, reflecting a commitment to sustainability. Yet, achieving this balance remains complex. Companies must weigh costs against environmental benefits. Flanging machines are becoming versatile but require continuous improvement. The focus is shifting toward long-term efficiency rather than short-term gains.

| Model | Flanging Capacity (mm) | Max Speed (rpm) | Power (kW) | Weight (kg) | Applications |

|---|---|---|---|---|---|

| Model A | 50 | 120 | 5 | 400 | Oil & Gas, Automotive |

| Model B | 70 | 100 | 7 | 500 | Construction, Manufacturing |

| Model C | 60 | 110 | 6 | 450 | Aerospace, Shipping |

| Model D | 80 | 130 | 8 | 600 | Heavy Industries, Marine |

| Model E | 75 | 115 | 7.5 | 550 | Pipelines, Energy |