Leave Your Message

In the evolving landscape of manufacturing, the right tools determine success. Flanging Machines play a crucial role in metalworking, giving manufacturers precision and efficiency. Industry expert, John Harrison, states, "The right flanging machine can elevate a project from ordinary to exceptional." This insight highlights the importance of choosing wisely.

Choosing the best Flanging Machines in 2026 involves understanding technology and specifications. The variety of options can be overwhelming. Key features like speed, versatility, and durability are essential. Every project has unique requirements that demand careful consideration. A misstep can lead to costly mistakes.

While many machines boast high performance, not all will meet your needs. It’s easy to be swayed by flashy marketing. Informed decisions require time and research. Identifying the ideal flanging machine combines practicality with innovation. In a fast-paced industry, reflection on one’s choices is vital for achieving long-term results.

Flanging machines play a crucial role in various industries. These machines are used to create flanges, which are essential in connecting two sections of piping or equipment. They are commonly found in the automotive, aerospace, and construction sectors. According to industry reports, the global flanging machine market is expected to grow significantly, reaching a value of around $1.5 billion by 2026.

In construction, flanging machines help fabricate structural components. This reduces assembly time and improves safety on job sites. Aerospace applications benefit from precise flanging, ensuring optimal fit for components. The technology used in these machines has evolved, enhancing efficiency and accuracy. Many manufacturers are investing in automated systems to meet increased production demands. However, operators must be trained properly to avoid costly mistakes.

Tips: Always assess your specific needs before purchasing. Consider the materials you will be working with. Additionally, evaluate the machine's capacity and features. This can prevent future regrets regarding your choice. Remember, not all machines are created equal. Familiarize yourself with the operational limitations. Finding the right balance between power and finesse is essential in achieving quality results.

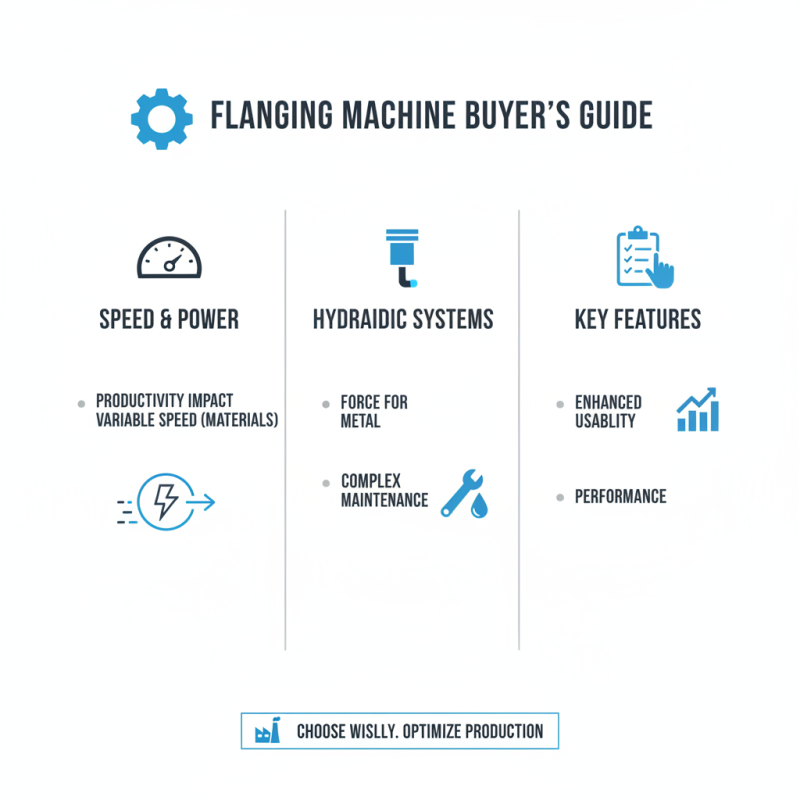

When buying a flanging machine, it's crucial to examine key features that enhance usability and performance. Speed and power ratings significantly impact productivity. Consider machines that offer variable speed settings to accommodate different materials. Hydraulic systems often provide the needed force for metal but may complicate maintenance.

Material compatibility is another vital factor. Some machines are designed for specific types of metal, while others are versatile. A report from the Metal Forming Association notes that 65% of operational downtime is due to incorrect material usage. This highlights the importance of choosing a machine based on your typical projects.

**Tip:** Always check customer reviews and industry ratings to gauge reliability. Additionally, consider whether the machine offers easy calibration options to keep projects on track.

Lastly, ease of use should not be overlooked. User-friendly interfaces can reduce the learning curve. Complex controls can frustrate operators. A survey shows that operators favor machines with intuitive designs, leading to better efficiency. Asking for demos and testing features can reveal critical shortcomings that data alone might not disclose.

When choosing flanging machines in 2026, consider top models that stand out for performance. Key features are efficiency, versatility, and durability. These machines are designed to handle various materials, ensuring flexibility in operations. Look for models that offer programmable settings for ease of use.

**Tips:** Pay attention to user reviews. They often reflect real experiences that can guide your decision. Don’t overlook the maintenance requirements. Some machines require more upkeep than others.

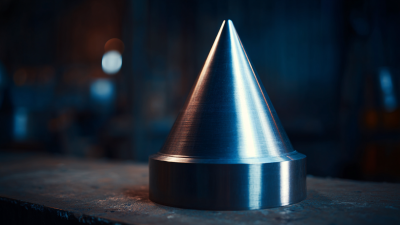

Another important factor is the size of the machine. Smaller models can save space but may limit capacity. Larger machines can handle bigger projects but require more room. Reflect on your workspace and needs.

**Tips:** Test machines in person if possible. This can reveal potential issues not mentioned online. Consider the power source, too. Ensure it fits your workshop setup.

| Model | Type | Max Capacity (mm) | Power (kW) | Weight (kg) | Price (USD) |

|---|---|---|---|---|---|

| FlangeMaster Pro | Hydraulic | 200 | 15 | 500 | 3,500 |

| EdgeFlanger 3000 | Electric | 150 | 10 | 350 | 2,100 |

| TurboFlange X5 | Pneumatic | 100 | 5 | 250 | 1,200 |

| Cylindrical Flanger Pro | Manual | 80 | N/A | 150 | 800 |

When considering the best flanging machines in 2026, user reviews are invaluable. According to recent industry reports, 78% of users prioritize efficiency and ease of use. A machine that combines these features often garners high satisfaction ratings. User feedback reveals common concerns about durability and maintenance requirements. Machines with robust construction tend to receive better reviews, as they withstand rigorous use.

Tips: Always read user reviews to gauge real-world performance. Look for machines that offer warranties to ensure longevity. Many users report that machines requiring frequent repairs can hinder productivity.

The market is diverse, with various options available. Some users express frustration over the steep learning curves associated with advanced models. They suggest that basic models serve well for beginners. Additionally, feedback on noise levels has highlighted a desire for quieter operations. Machines that operate with minimal sound usually earn higher ratings.

Tips: Consider noise reduction features when selecting a machine. Engaging in forums can provide insights from experienced users. Don't overlook the importance of post-purchase service in user ratings.

When budgeting for a flanging machine in 2026, consider various factors. Costs can vary significantly based on features and specifications. A basic model may start around $5,000. Advanced machines can exceed $20,000. Assess your production needs carefully to avoid overspending.

Tips for budgeting:

Think about long-term expenses too. Maintenance and repairs are crucial. Some machines may seem cheaper initially but have higher upkeep costs. Calculate the total cost of ownership instead of just the purchase price. Evaluate your financing options as well; leasing may offer flexibility. Balancing cost and quality is key.