Leave Your Message

In today's competitive manufacturing landscape, selecting the right Hot Spinning Machine is critical. As industries evolve, companies seek efficient production methods to reduce costs and enhance quality. According to a recent report by Industry Insights, manufacturing efficiency can improve by up to 40% with the right machinery. This highlights the importance of making informed choices about equipment.

Hot spinning is a specialized process that allows manufacturers to create complex shapes with minimal waste. As reported by Global Manufacturing Research, the demand for high-precision components has surged by 30% in recent years. This trend emphasizes the need for advanced Hot Spinning Machines with innovative technologies. Companies that fail to adapt may find themselves at a disadvantage.

However, selecting a machine isn’t without challenges. Not all machines meet the required specifications. Many manufacturers still struggle with outdated equipment, hindering their productivity. Reflecting on these issues, the 2026 options in Hot Spinning Machines need thorough evaluation. Understanding their capabilities is essential for future growth and competitiveness.

Hot spinning technology has gained traction in the manufacturing sector. It enables the creation of complex shapes with high precision. Recent industry reports highlight the efficiency of hot spinning over traditional forging techniques. In fact, the Global Spinning Machinery Market was valued at $XX billion in 2022, with a projected growth rate of XX% by 2026.

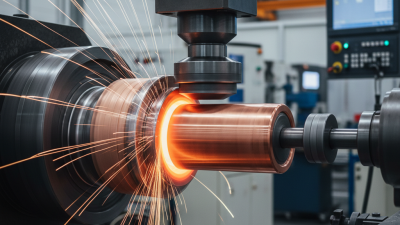

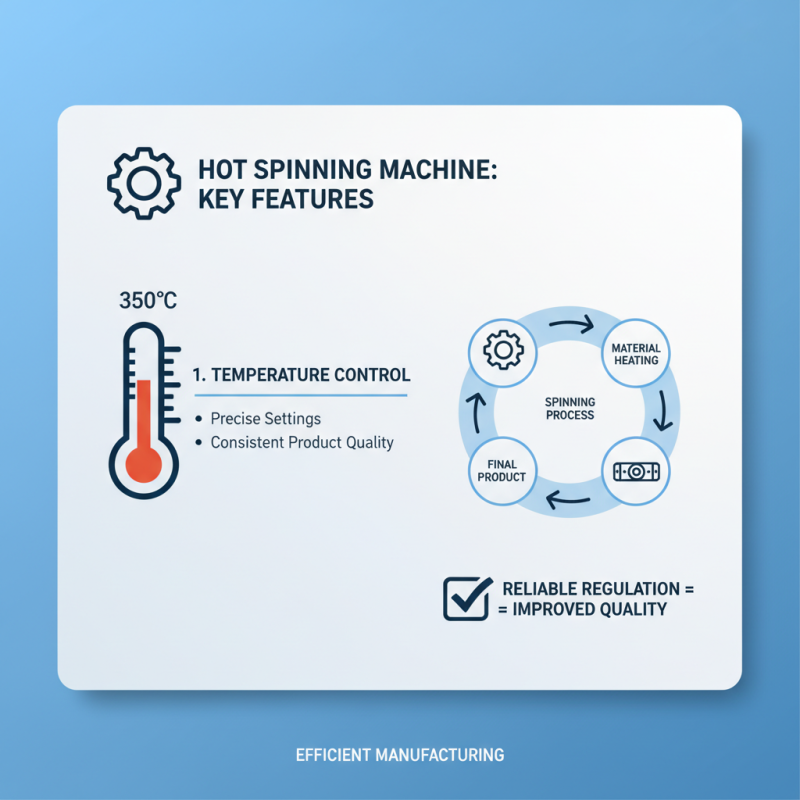

The hot spinning process involves heating metal and using spinning forces to shape it. This method offers reduced material waste, which is particularly beneficial in industries that rely on costly raw materials. For instance, studies show that hot spinning can lower material usage by up to 30%. However, achieving consistent quality can be a challenge. Variability in temperature and spinning speed often leads to defects that require additional quality control measures.

Moreover, the energy consumption during hot spinning warrants scrutiny. While more efficient than some processes, the heating stage can be energy-intensive. Manufacturers must balance between speed and sustainability. As the industry evolves, ongoing improvements are vital. Exploring new materials and refining techniques could mitigate energy costs and enhance reliability in hot spinning operations.

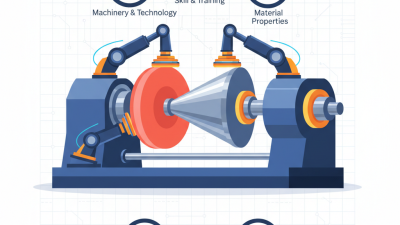

When selecting a hot spinning machine, various key features must be considered to ensure efficient manufacturing. One essential aspect is temperature control. Machines should provide precise temperature settings for materials. This feature enhances the consistency of the final product. Reliable temperature regulation can significantly impact the quality of spun components.

Another critical element is speed and flexibility. A good hot spinning machine must adapt to different materials and shapes. Machines that offer adjustable speed settings allow operators to fine-tune the spinning process. This adaptability can lead to better results and reduced waste. However, some machines may lack these features, leading to production delays.

Efficiency also hinges on ease of use. A user-friendly interface enhances operator productivity. Complex controls can slow down the workflow. Additionally, maintenance accessibility is crucial. Machines that are difficult to maintain can result in downtime. This downtime can disrupt production schedules. Reflecting on these aspects can help manufacturers choose wisely and enhance operational efficiency.

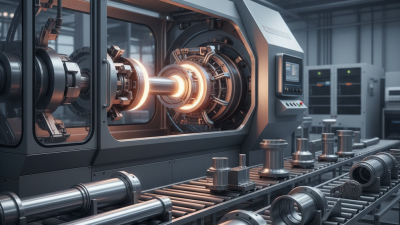

When exploring hot spinning machines for 2026, consider functionality and efficiency. Advanced models come with enhanced cooling systems and programmable controls. They help optimize production rates and reduce energy consumption. These features can substantially impact your overall manufacturing process.

Tips: Always compare specifications carefully. Look for user reviews that highlight real-world performance. It's essential to balance cost with capabilities. Don't settle for flashy features without practical benefits. Examine warranty and support services; this can save future headaches.

Our manufacturing needs are evolving. We often overlook the importance of maintenance. Routine checks are crucial for keeping machines in optimal condition. A minor oversight can lead to significant downtime and increased costs. Investing in training for operators can also boost productivity and safety. Consider the long-term advantages of proper education on handling these machines.

When analyzing the performance of hot spinning machines, several factors come into play. Efficiency is crucial. These machines convert metal into shapes using high heat and pressure. The precision of this process can significantly affect production quality. Therefore, understanding the differences between various models is essential for manufacturers.

Tips: Consider the maximum operating temperature of machines. Higher temperatures may enable more precise spinning. However, they can also lead to increased energy costs. Evaluate the machine's tooling options. Different materials and geometries can alter performance.

Some machines offer unique features, like automated controls, which can enhance consistency. Yet, automation can complicate repairs. Regular maintenance remains critical, regardless of machine capabilities. Without proper care, even the best machines can underperform.

Tips: Establish a regular inspection schedule. This helps catch potential issues early. Check for wear and tear on critical components. Ignoring these can lead to downtime, affecting production rates. Always collect data on machine performance. Analyzing this can highlight areas for improvement.

The future of hot spinning technology is promising. As industries aim for efficiency, advancements become crucial. Reports indicate that manufacturers could boost productivity by 30% through automation and precision engineering. Automated systems reduce human error and enhance consistency in production processes.

A notable trend in hot spinning is the integration of AI and machine learning. These technologies predict and mitigate issues before they arise. It is estimated that predictive maintenance could decrease downtime by 25%. However, the implementation of such systems may require significant investment and training, raising concerns in smaller operations.

Despite these trends, challenges remain. Not all manufacturers may adapt quickly to new technologies. There's a risk of creating a skills gap, as experienced workers retire. Investing in workforce training is essential for maximizing new technologies. Balancing innovation with practical implementation will determine the future of hot spinning efficiency.