Leave Your Message

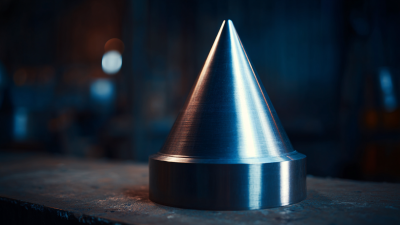

In the realm of modern manufacturing, the Spinning Metal Process stands out as a vital technique for creating precise and efficient components. As industries increasingly demand higher quality and faster production cycles, mastering this process has become essential. From aerospace to automotive applications, the ability to manipulate metal into intricate shapes while maintaining tight tolerances plays a crucial role in ensuring the performance and reliability of end products.

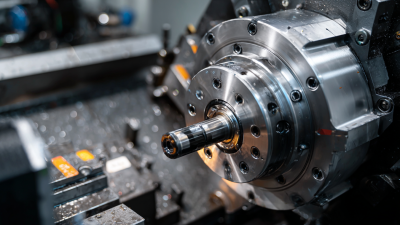

This article delves into the ten best techniques in the Spinning Metal Process, highlighting innovative methods that enhance both accuracy and efficiency. As we explore these techniques, it becomes evident that advancements in technology, such as computer numerical control (CNC) and the integration of advanced materials, have revolutionized traditional spinning practices. By embracing these strategies, manufacturers can not only improve productivity but also achieve exceptional surface finishes and form consistency.

Whether you are a seasoned professional looking to refine your skills or a newcomer eager to understand the nuances of metal spinning, this guide will provide invaluable insights. Join us as we uncover the essential techniques that define the future of the Spinning Metal Process, setting the stage for operational excellence and competitive advantage in the marketplace.

Advanced tooling strategies play a crucial role in enhancing the accuracy and efficiency of the metal spinning process. Utilizing high-quality tools made from durable materials can significantly reduce wear and tear, ensuring consistent performance over time. Tools designed with precision-engineered geometries allow for better contact with the metal, leading to minimized deformation and improved surface finish. Incorporating advanced coatings on tooling can also reduce friction, which not only prolongs tool life but enhances the overall quality of the spun products.

Tips for achieving enhanced metal spinning accuracy include regularly maintaining and calibrating machinery to ensure optimal performance. Additionally, consider experimenting with different tooling configurations to find the best fit for specific metal types and thicknesses. Implementing a systematic approach to monitoring tool wear can help in making timely replacements before they affect the quality of the finished product. Finally, employee training sessions on the latest techniques will empower operators to execute processes with improved dexterity and understanding, contributing to overall production quality.

Integrating these advanced tooling strategies into your metal spinning operations can lead to significant gains in productivity and output quality. Continuous assessment and adaptation of these methods will not only keep processes efficient but will also drive innovation in metal spinning applications.

In the field of metal spinning, achieving precision while minimizing distortion is paramount. Innovative workpiece clamping techniques play a crucial role in this process. One effective method involves utilizing specialized clamps that evenly distribute pressure across the workpiece, reducing the risk of deformation during spinning operations. This not only preserves the integrity of the part but also ensures that it meets the stringent tolerances required by manufacturers.

Tips: When selecting clamping devices, consider adjustable clamps that can accommodate various workpiece geometries. This flexibility allows for quick adjustments and improved efficiency. Additionally, employing hydraulic clamps can enhance clamping force uniformity, further mitigating distortion risks.

Another effective technique is pre-welding components before the spinning process. By securing parts together through welding, the likelihood of movement during metal spinning is significantly decreased. This proactive approach aids in maintaining alignment and achieving better final dimensions, ultimately resulting in a smoother production flow and reduced downtime.

Tips: Always ensure proper joint preparation and select appropriate welding methods to enhance joint strength and minimize residual stress. Regularly inspecting clamps and welded joints is crucial to maintaining optimal performance throughout the production process.

This chart demonstrates the precision loss and efficiency utilization of different innovative workpiece clamping techniques in metal spinning. Techniques are compared based on their performance metrics to highlight the best practices for optimal results.

Utilizing Computer-Aided Design (CAD) significantly enhances efficiency and precision in metal spinning processes. CAD enables engineers to create detailed 3D models, allowing for the simulation of the spinning operations before actual production. According to a report from Market Research Future, the demand for CAD software in the aerospace and automotive sectors is expected to grow at a CAGR of 7.5% from 2021 to 2028, highlighting the importance of advanced design tools in today's manufacturing landscape. Incorporating these tools not only reduces material waste but also minimizes the time taken for product modifications, leading to shorter production cycles and improved cost-effectiveness.

Tips: When integrating CAD into your metal spinning workflow, ensure that your design software is compatible with CNC machines. This allows for seamless transitions from digital models to physical production. Additionally, consider conducting regular training sessions for your team to keep them updated on software advancements and methodologies that can further streamline operations.

Moreover, employing CAD tools encourages innovative design practices, enabling the creation of complex geometries that were previously unachievable. A recent analysis revealed that companies utilizing CAD in their spinning processes reported a 30% increase in production efficiency. This is particularly beneficial in industries where precision is paramount, such as aerospace, where even the smallest design inaccuracies can lead to significant safety concerns.

| Technique | Description | Benefits | Efficiency Improvement (%) | Precision Level |

|---|---|---|---|---|

| Computer-Aided Design (CAD) | Utilizes software for precise modeling and simulation of spinning processes. | Increased design accuracy, reduced errors | 30% | High |

| Finite Element Analysis (FEA) | Analyzes metal deformation under various conditions for better predictions. | Enhanced process understanding and optimization | 25% | Medium |

| Tool Path Optimization | Refines the tool's movement for maximum efficiency. | Reduced machining time, lower tool wear | 20% | Medium |

| Real-time Monitoring | Uses sensors to track parameters during the spinning process. | Immediate adjustments, reduced defects | 15% | High |

| Spindle Speed Control | Adjusts spinning speed based on material and design. | Improved material properties, lower energy consumption | 10% | High |

| Material Selection Algorithms | AI-assisted selection of optimal materials for spinning. | Better product quality, lower failure rates | 18% | Medium |

| Tooling Innovations | Use of advanced materials and designs in tooling. | Increased lifespan of tools, reduced downtime | 22% | High |

| Workflow Automation | Automating repetitive tasks to enhance productivity. | Reduced labor costs, increased output | 35% | Medium |

| Predictive Maintenance | Analyzes equipment health to predict failures before they occur. | Minimized downtime, extended equipment life | 28% | High |

Effective heat management is crucial in the spinning metal process to ensure the optimal performance of materials. According to a report by the International Journal of Advanced Manufacturing Technology, improper heat control can lead to defects such as warping and reduced material strength, adversely affecting the final product's quality. In this context, maintaining an optimal temperature range is essential. Techniques such as pre-heating the workpiece and utilizing controlled cooling systems can significantly improve the material's ductility, allowing for more precise shaping and reducing the likelihood of fractures during forming.

Additionally, research from the Journal of Materials Processing Technology highlights that implementing thermal monitoring during the spinning process can lead to improved efficiency. By employing infrared thermography, manufacturers can accurately track temperature fluctuations in real-time, enabling them to make necessary adjustments promptly. This proactive approach not only enhances the overall precision of the spinning operation but also contributes to cost savings by minimizing material waste and increasing tool life. Thus, integrating effective heat management practices is paramount for achieving the desired balance between precision and efficiency in metal spinning operations.

In the world of metal spinning, maintaining precision is paramount. Quality control measures play a crucial role in ensuring that the final product meets the exact specifications required by various industries. Key techniques to achieve optimal precision involve rigorous inspection processes at each stage of production, from raw material selection to the final touch-ups. Regular calibration of machinery and tools can drastically reduce the risk of errors, enhancing the overall efficiency of the spinning process.

Tips for ensuring precision include implementing strict measurement protocols using advanced instruments. Employing digital measuring tools can provide real-time feedback, allowing for immediate adjustments that prevent deviations. Furthermore, the training of staff on quality control methods enhances their ability to identify and rectify potential issues proactively.

Another effective strategy is to establish a feedback loop that incorporates data from completed projects. Analyzing this data helps in refining future processes and improving precision further. By emphasizing quality control throughout the metal spinning process, manufacturers can not only enhance productivity but also ensure that their products meet the highest standards of quality demanded by clients.