Leave Your Message

Choosing the right Copper Spinning Machine for your business is a crucial decision that can significantly impact your production efficiency and overall success. As John Smith, a renowned expert in metalworking technologies, aptly stated, “Investing in the right equipment not only enhances productivity but also ensures quality craftsmanship.” With the growing demand for finely crafted copper products, the selection of an appropriate copper spinning machine becomes even more essential for manufacturers looking to meet industry standards and customer expectations.

In today's competitive market, the intricacies of selecting a Copper Spinning Machine involve several factors, including the machine's capabilities, ease of use, and durability. The right machine can streamline your production processes, allowing you to create intricately designed copper products with precision and efficiency. Understanding these aspects is vital for making an informed choice that aligns with your business needs and growth objectives. By delving into the key considerations and consulting expert insights, businesses can navigate the complexities of this critical equipment selection and set themselves up for success in the copper manufacturing industry.

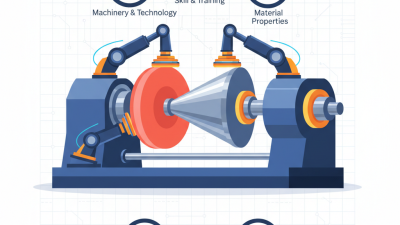

When selecting a copper spinning machine for your business needs, several key factors must be taken into account to ensure optimal performance and efficiency. Firstly, consider the machine's size and capacity. The dimensions should fit within your workspace while being capable of handling the volume of copper pieces you intend to produce. A larger capacity machine can often save time in production, but make sure it aligns with your specific requirements.

Another crucial factor is the machine's technology and features. Modern copper spinning machines may come equipped with advanced controls, automation options, and precision tools that enhance operational efficiency and product quality. Assess whether the machine offers the flexibility to perform various spinning techniques, as this can greatly influence your production capabilities. Additionally, ease of use and maintenance should not be overlooked; machines that are user-friendly and require minimal upkeep will contribute to smoother operations and less downtime.

Lastly, evaluate the availability of technical support and training from the manufacturer. It's essential to ensure that you have access to resources that can help you troubleshoot and maximize the use of your equipment. A machine is only as good as the knowledge behind it, so having ongoing support can significantly impact your success in utilizing the copper spinning machine effectively.

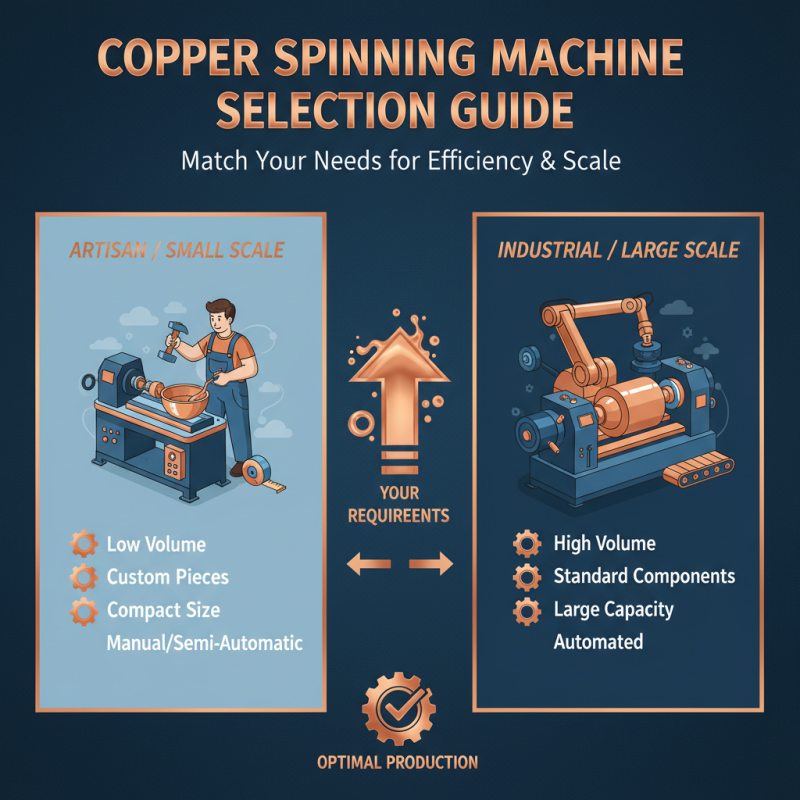

When selecting a copper spinning machine, it's essential to understand the different types available in the market to meet your specific business needs. The major categories include manual, semi-automatic, and fully automatic machines. Manual machines are ideal for smaller operations or those just entering the copper spinning field, as they are typically more affordable and require less technical knowledge. However, they can be labor-intensive and time-consuming, making them less suitable for larger production runs.

On the other hand, semi-automatic and fully automatic machines are designed for higher volume production, significantly increasing efficiency. According to industry reports, fully automatic machines can enhance production rates by up to 60% compared to manual alternatives, which is a critical factor for businesses aiming to scale operations. These advanced machines also reduce the risk of human error, ensuring consistency and quality in output.

**Tips:** When comparing options, consider the size and weight of the parts you'll be spinning, as this will influence the type of machine you need. Additionally, assess the machine's energy consumption, as more efficient models can lead to long-term savings. Investing in a copper spinning machine that offers flexibility for different sizes and styles can also enhance your product range, making your business more competitive.

| Machine Type | Key Features | Recommended For | Price Range |

|---|---|---|---|

| Manual Copper Spinning Machine | Cost-effective, ideal for small batches, hands-on operation | Hobbyists, startups | $1,000 - $3,000 |

| Semi-Automatic Copper Spinning Machine | Faster production, reduced manual effort, programmable settings | Small to medium businesses | $5,000 - $10,000 |

| Fully Automatic Copper Spinning Machine | High efficiency, minimal labor, continuous operation | Large manufacturing plants | $15,000 - $50,000 |

| CNC Copper Spinning Machine | Precision control, complex designs, versatile materials | High-tech industries, custom fabricators | $20,000 - $100,000 |

When selecting a copper spinning machine for your business, it's crucial to focus on key features that enhance performance and efficiency. One of the most important aspects is the machine's build quality. A robust and durable frame, often made of heavy-duty steel or cast iron, ensures stability and reduces vibration during operation. According to industry reports, machines that minimize vibration can achieve up to 20% better precision in spinning processes, which is essential for producing high-quality copper products.

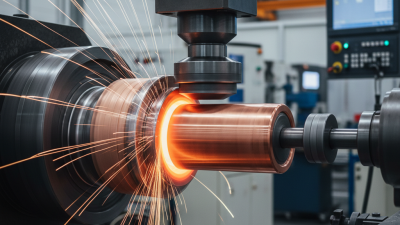

Another critical feature to consider is the machine's motor power and speed settings. High-quality copper spinning machines typically come with variable speed controls, allowing operators to adjust the speed based on the thickness and specifics of the copper material. Research indicates that a machine with a motor in the range of 1 to 5 horsepower can handle diverse production needs, providing flexibility for batch production and custom work. Additionally, automatic feeding mechanisms are increasingly favored in the industry, as they can boost productivity by reducing manual labor and minimizing material waste.

Finally, look for machines equipped with advanced safety features and user-friendly controls. Safety measurements such as emergency stop buttons and safety guards help reduce the risk of accidents in the workshop. User-friendly interfaces and digital displays can streamline the setup and operation, enhancing overall efficiency. Reports suggest that manufacturers who prioritize ergonomics and safety see a significant decrease in operator downtime—up to 30%—which highlights the importance of selecting a well-designed copper spinning machine that meets the needs of your business effectively.

When selecting a copper spinning machine for your business, it's crucial to start by understanding your specific requirements. Consider the scale of your operations—are you producing small artisan pieces or large industrial components? This fundamental aspect will guide your decision on the machine's size and capacity, ensuring it aligns with your production volume and workflow efficiency.

Furthermore, think about the complexity of your designs. If your projects frequently incorporate intricate shapes and fine details, you will need a machine that offers precision and flexibility. Evaluate the technical capabilities of potential machines, including speed settings and tooling options, to determine if they meet the demands of your design specifications. Lastly, consider the space and power constraints of your facility; these logistical factors can significantly impact the performance of the machine you choose.

When budgeting for a copper spinning machine, it's essential to start with a clear understanding of your business needs. The initial cost of the machine is only one aspect; additional expenses such as installation, maintenance, and training should also be factored in. Analyzing your production volume and specific requirements will guide you in determining the right machine type and features, which directly influence the overall cost. For instance, a more advanced machine may come with higher upfront costs but could enhance productivity and reduce labor costs in the long run.

To create an effective budget, gather quotes from manufacturers and suppliers, while also considering the cost of potential upgrades or additional tools necessary for optimal operation. It’s wise to set aside a contingency fund to cover unexpected expenses, such as repairs or software updates. Evaluating the cost-benefit ratio of various machines will help ensure that your investment not only fits within your budget but also aligns with the growth objectives of your business. By carefully considering all financial aspects, you can make a well-informed decision that supports your production goals.