Leave Your Message

In the world of manufacturing, the choice of equipment plays a pivotal role in the success of any project, particularly when it comes to achieving precision and efficiency. One such essential equipment is the Metal Spinning Cone, which has gained recognition for its ability to produce high-quality components for a variety of applications. According to John H. Kramer, a leading expert in the metal spinning industry, "The selection of the right Metal Spinning Cone not only influences the production quality but also significantly impacts the overall operational costs."

Choosing the appropriate Metal Spinning Cone requires careful consideration of various factors, including material compatibility, design specifications, and production volume. Each project presents unique challenges that can be met by the right spinning cone tailored to specific needs. As Kramer emphasizes, understanding the nuances of your project will guide you in making an informed decision, ensuring both effectiveness and efficiency in your operations. In this article, we will explore the essential criteria for selecting the best Metal Spinning Cone, thereby equipping you with the knowledge to enhance your project’s success.

Selecting the right metal spinning cone for your project involves several key factors that can significantly affect the overall outcome.

First and foremost, consider the material type you'll be working with. Certain metals require specific spinning techniques; for example, aluminum and copper are more malleable and can be shaped easily, while harder materials like stainless steel may require more advanced machinery and techniques. Understanding the properties of the material helps in choosing a cone that can handle the specific stresses and strains during the spinning process.

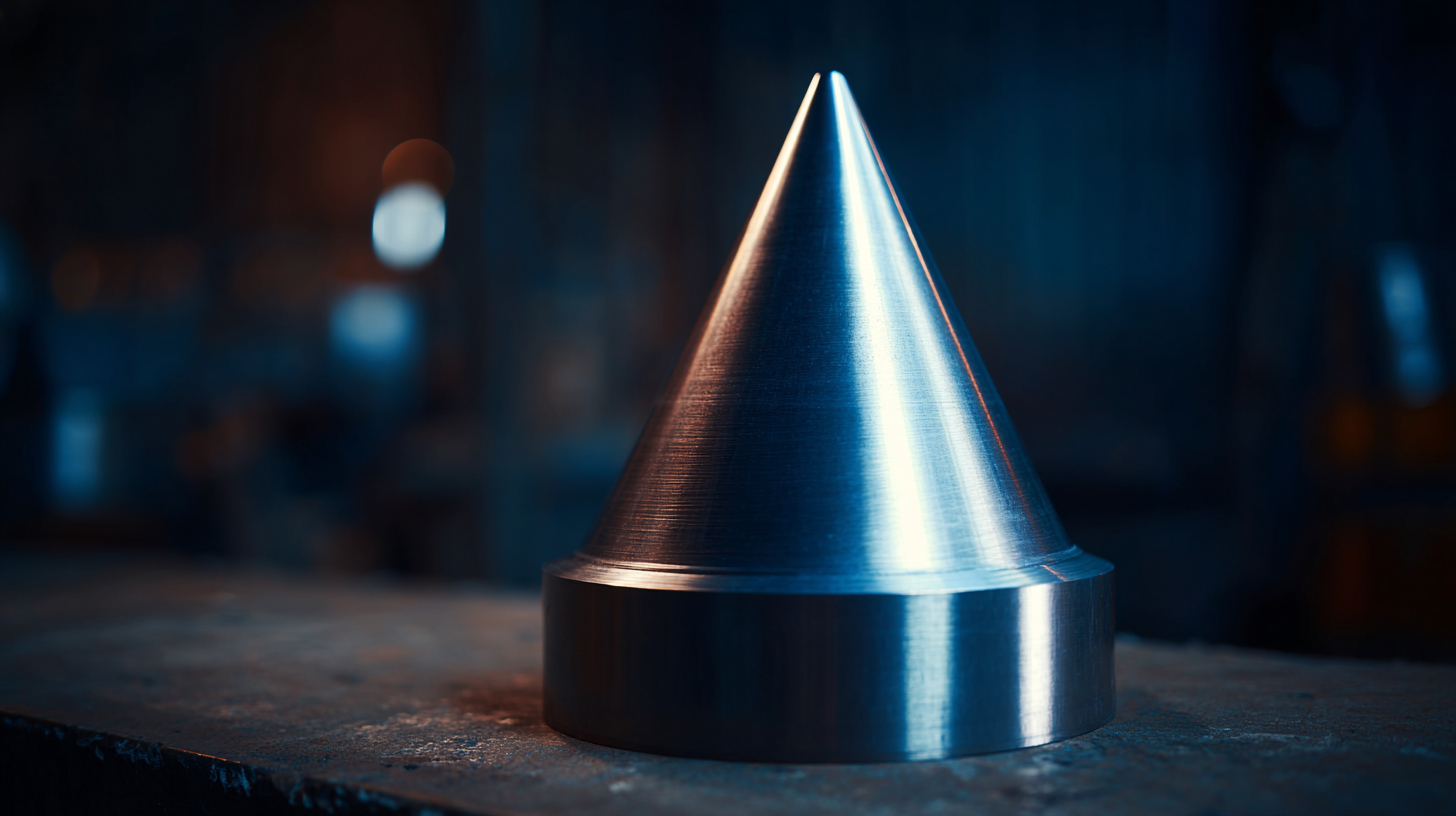

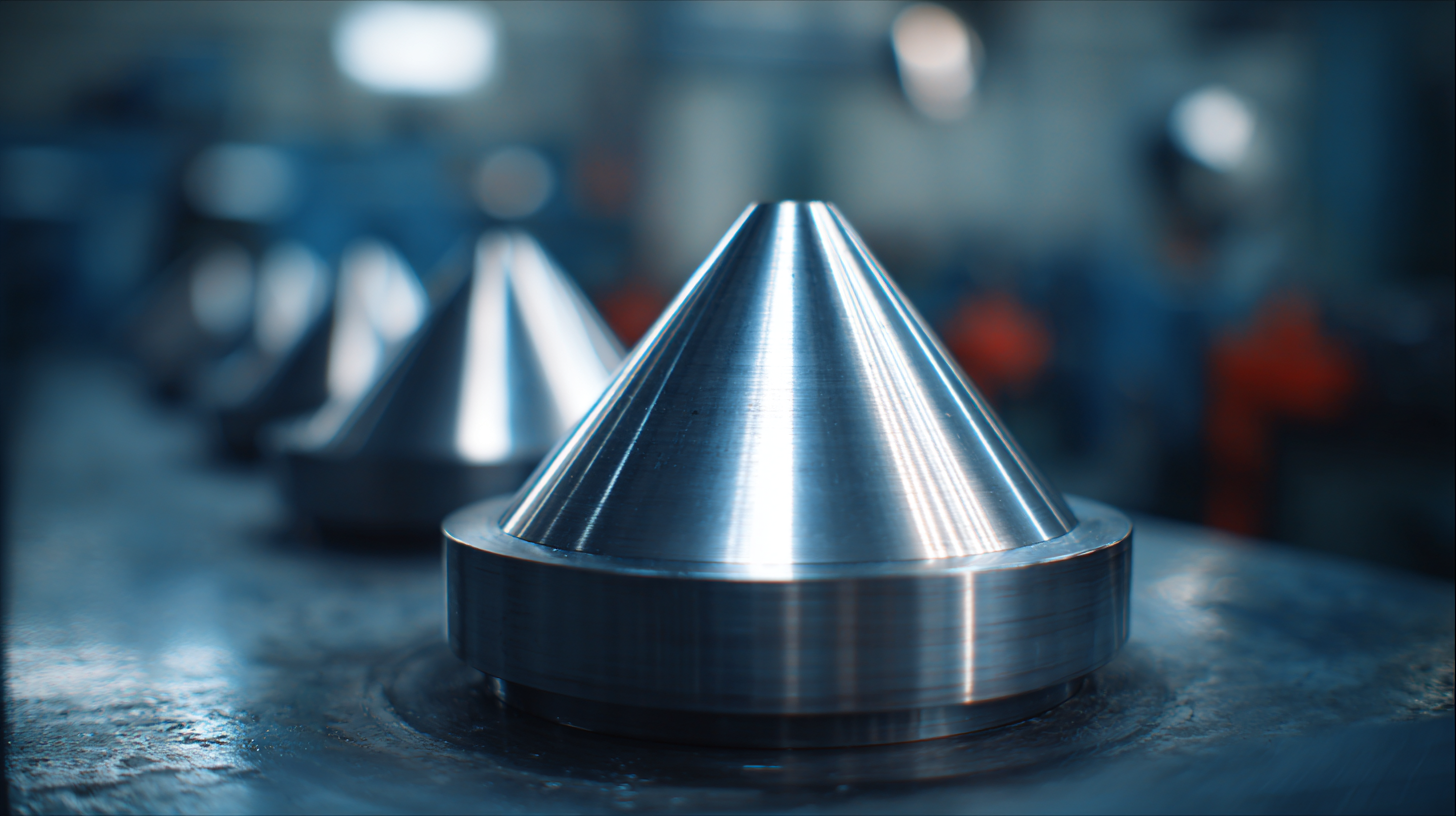

Another crucial factor is the size and design specifications of your project. The diameter and height of the cone should align with the dimensions of the final product you are aiming to create. Additionally, think about the cone’s shape—whether you need a straight-sided cone or one with a tapered or rounded design. Having precise measurements and design details will ensure that the metal spinning process runs smoothly and yields the desired results. Finally, considering the production volume can also guide your choice; for high volume production, a more durable and efficient cone is essential to maintain consistency and reduce waste.

When selecting a metal spinning cone for your project, the choice of material is crucial as it directly impacts both durability and performance. Common materials used in metal spinning include aluminum, stainless steel, and brass. Aluminum is lightweight and offers good corrosion resistance, making it ideal for applications that require ease of handling and lower weight. However, while it provides sufficient strength for many projects, it may not stand up to high-temperature environments as well as other metals.

Stainless steel, on the other hand, is renowned for its strength and durability. It withstands harsher conditions and is resistant to rust and corrosion, which makes it suitable for applications in industries such as aerospace and automotive. While more expensive than aluminum, stainless steel's longevity can lead to lower maintenance costs over time. Brass, characterized by its excellent machining properties and aesthetic appeal, is often chosen for decorative applications or where wear resistance is required. Each material brings unique advantages, and understanding their properties is key to selecting the right metal spinning cone for your specific needs.

When selecting a metal spinning cone for your project, understanding the cost-effectiveness of various models is crucial. A comparative analysis reveals that while some high-end models offer advanced features and superior build quality, they may not always provide the best value for every application. Many mid-range cones combine adequate performance with affordability, making them attractive options for projects with budget constraints. This balance between cost and functionality is a key factor to consider for small to medium-scale operations.

When selecting a metal spinning cone for your project, understanding the cost-effectiveness of various models is crucial. A comparative analysis reveals that while some high-end models offer advanced features and superior build quality, they may not always provide the best value for every application. Many mid-range cones combine adequate performance with affordability, making them attractive options for projects with budget constraints. This balance between cost and functionality is a key factor to consider for small to medium-scale operations.

In addition to initial purchasing costs, it's essential to examine the long-term operational expenses associated with each model. Factors such as maintenance requirements, durability, and the availability of replacement parts can significantly affect the overall cost-effectiveness of a spinning cone. For instance, a slightly more expensive cone that offers higher durability and requires less frequent maintenance may prove cost-effective over time, potentially outperforming cheaper alternatives. Thus, a thorough cost-benefit analysis that considers both upfront investments and ongoing expenses is vital for making an informed decision tailored to specific project needs.

When selecting the best metal spinning cone for your project needs, it's crucial to consider the role of precision engineering in enhancing efficiency. Recent advancements in precision engineering have shown that technologies such as TruRoll can significantly improve manufacturing processes by achieving craft-level precision at scale. This level of accuracy ensures that the metal spinning cones produced meet rigorous performance standards, optimizing the output for diverse applications.

Moreover, the evolution of high-precision drives is pivotal in various industries, akin to what has been implemented in solar power projects. The precise positioning of components, similar to how solar panels must be aligned with sunlight, highlights the need for exactness in metal spinning applications. Continued investment in precision technologies is yielding measurable improvements in efficiency and product reliability.

**Tips**:

1. When assessing metal spinning cones, pay attention to the manufacturing technology utilized; advanced methods can lead to better dimensional accuracy and surface finish.

2. Always evaluate the operating conditions and demands of your project; precise engineering can lead to tailored solutions that enhance performance and reduce operational costs.

| Dimension | Specification | Material | Precision Level | Application Area |

|---|---|---|---|---|

| 10 cm Diameter | Thickness: 2 mm | Aluminum Alloy | High Precision | Automotive Parts |

| 15 cm Diameter | Thickness: 3 mm | Steel | Medium Precision | Aerospace Components |

| 20 cm Diameter | Thickness: 4 mm | Copper | High Precision | Electrical Applications |

| 25 cm Diameter | Thickness: 5 mm | Titanium | Medium Precision | Medical Devices |

| 30 cm Diameter | Thickness: 6 mm | Stainless Steel | High Precision | Industrial Equipment |

The landscape of metal spinning cone technologies is rapidly evolving, driven by advancements in materials science and manufacturing processes. One significant trend is the shift towards automation and robotics, which enhances precision and reduces production times. Automated systems allow for consistent quality in the production of metal spinning cones, making it easier for manufacturers to meet the growing demand for high-quality components across various industries, from aerospace to automotive.

Additionally, there is a growing emphasis on sustainability and eco-friendly practices in metal spinning. Companies are increasingly adopting techniques that minimize waste and energy consumption during the manufacturing process. Innovations such as using recycled metals and developing hybrid spinning techniques not only reduce the environmental impact but also cater to the rising consumer preference for sustainable products. These industry trends highlight a broader commitment to sustainable manufacturing practices while continuing to push the boundaries of what metal spinning technology can achieve.