Leave Your Message

In the realm of manufacturing and fabrication, the metal spinning tool has increasingly become an indispensable element in producing intricate and high-quality components. According to the latest industry reports, the global market for metal spinning tools is projected to grow at a significant CAGR of approximately 7.5% through the next five years. This growth can be attributed to the rising demand for lightweight and durable metal parts across various industries including aerospace, automotive, and general engineering.

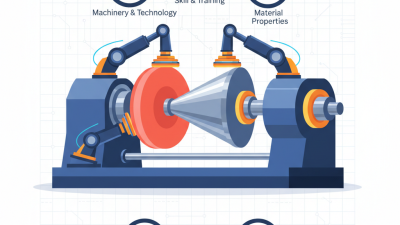

Choosing the right metal spinning tool for specific projects requires an understanding of the various types of tools available, their configurations, and the materials they can manipulate. With numerous options available in today’s marketplace, it is critical for manufacturers and craftsmen to evaluate their specific needs, project requirements, and production capabilities. For instance, the diameter, material type, and wall thickness of the pieces being spun can greatly influence the effectiveness and efficiency of the tools used.

As the industry continues to evolve, staying informed about advancements in metal spinning technology is essential for professionals aiming to enhance productivity and quality in their projects. Selecting the best metal spinning tool not only optimizes operational processes but also ensures that end products meet the highest standards of precision and durability. Understanding these key factors will empower users to make informed decisions, ultimately leading to improved outcomes in their manufacturing endeavors.

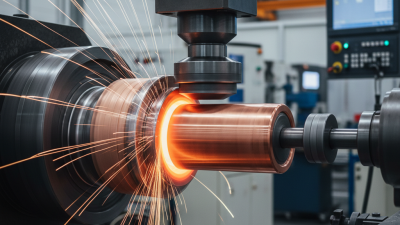

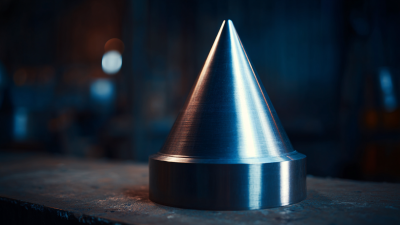

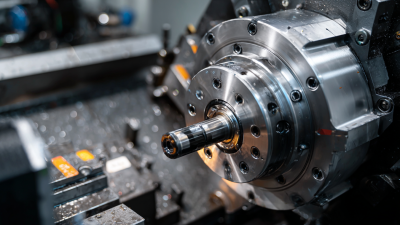

Metal spinning is a versatile manufacturing process that utilizes various tools to reshape metal into desired forms. Understanding the types and applications of metal spinning tools is crucial for selecting the right equipment for your specific projects. Common types of metal spinning tools include manual spin forming machines, CNC lathes, and hydraulic presses. Each type offers distinct benefits: manual tools are typically more affordable and suitable for smaller production runs, while CNC lathes provide precision and efficiency for complex geometries, making them ideal for high-volume manufacturing.

According to industry reports, the metal spinning market is projected to grow significantly, reaching a value of approximately $2.3 billion by 2026, driven by advancements in machinery and increasing automation in the manufacturing sector. Applications of metal spinning tools range from producing automotive parts to creating intricate decorative items. For instance, in aerospace and automotive industries, metal spinning is often employed for components such as fuel tanks and ducting systems due to its ability to create lightweight and robust shapes. As the demand for customized and lightweight components rises, the choice of metal spinning tools will increasingly influence manufacturing efficiency and product quality.

When selecting the best metal spinning tool for your projects, several key features should be considered to ensure optimal performance and suitability for your specific needs. First and foremost, the tool's material and construction play a crucial role in its durability and effectiveness. High-grade steel and aluminum are preferred materials due to their strength and resistance to wear, which can lead to longer lifespan and reduced maintenance costs. According to a report by MarketsandMarkets, the metal forming tools market is expected to grow significantly, indicating a rising demand for quality tools that enhance operational efficiency.

Another critical feature to evaluate is the tool's versatility and ease of use. Many modern metal spinning tools come equipped with adjustable settings that allow operators to work with various materials and thicknesses, making them suitable for an array of projects, from intricate designs to large-scale manufacturing. A study published in the Journal of Manufacturing Processes highlights that adaptable tools can increase production rates by up to 30%, underscoring the importance of flexibility in metal spinning processes.

Tips for choosing the right tool include assessing your project requirements and the types of metal you'll be working with. It's beneficial to opt for tools with user-friendly interfaces and robust safety features, which can significantly enhance the user experience and reduce the risk of accidents. Additionally, consider tools with good customer reviews and support services, as this can be an indicator of reliability and effectiveness in tackling various spinning tasks.

When selecting a metal spinning tool for your projects, evaluating the quality and durability of the tool is paramount. High-quality metal spinning tools are typically made from robust materials that can withstand the rigors of repeated use. Look for tools that are crafted from hardened steel or high-grade alloys, as these materials can resist wear and deformation, ensuring longevity. Additionally, pay attention to the craftsmanship: tools that undergo rigorous quality control processes usually exhibit finer finish and better overall performance.

Durability should also be assessed in terms of the tool’s ability to maintain precise tolerances and functionality over time. Consider features such as reinforced bearings and solid construction, which can significantly enhance a tool's lifespan. Furthermore, it is essential to read user reviews or case studies that can provide insight into how the tools perform under different conditions. Investing in a tool that not only meets your immediate needs but also stands the test of time will ultimately enhance your productivity and the quality of your finished products.

| Tool Type | Material | Weight (lbs) | Durability Rating (1-10) | Typical Applications |

|---|---|---|---|---|

| Manual Metal Spinning Lathe | Steel | 150 | 8 | Small scale production, Art pieces |

| CNC Metal Spinning Machine | Aluminum | 250 | 9 | Automotive parts, Aerospace components |

| Hydraulic Metal Spinner | Stainless Steel | 300 | 10 | High-volume manufacturing, Precision parts |

| Bench Top Spinning Tool | Cast Iron | 80 | 7 | Hobby projects, Decorative items |

| Portable Spinning Tools | Aluminum Alloy | 35 | 6 | Field repairs, Travel projects |

When choosing a metal spinning tool, assessing the cost versus performance is crucial for achieving the best results for your projects. High-performance tools often come with a higher price tag, but they can offer better durability, precision, and efficiency. It's essential to evaluate whether the enhanced features justify the investment based on the complexity and frequency of your projects. For hobbyists or those working on less demanding tasks, a more economical tool may suffice, allowing them to maintain productivity without overextending their budget.

Conversely, professionals and serious enthusiasts may find that investing in higher-end models pays off over time. These tools usually incorporate advanced technology that can streamline the spinning process, thereby reducing setup time and increasing output. It's also beneficial to consider the resale value and longevity of the tools. In essence, a careful analysis of the trade-off between upfront costs and long-term performance can lead to a more informed decision, ensuring that the chosen metal spinning tool aligns perfectly with both current and future needs.

When selecting a metal spinning tool, understanding the scale of your projects is crucial. For smaller-scale endeavors, such as hobbyist crafts or light manufacturing, a manual spinning tool may suffice. These tools are often more affordable and are suited for intricate designs and low-volume production. They allow for greater tactile control, making them ideal for those who are just starting out in metal spinning or who require precision for detailed work. Additionally, these tools are portable and easy to store, making them suitable for limited workshop spaces.

On the other hand, larger-scale projects, such as industrial manufacturing or fabrication of multiple components, necessitate a more robust, automated metal spinning tool. These advanced machines are designed to handle higher volumes and provide consistent results across numerous identical items. They come equipped with features that enhance efficiency, such as adjustable speeds and the ability to accommodate various metal thicknesses.

When choosing a tool for larger projects, consider factors like space, power supply, and the types of materials you will be working with, as these will influence the overall performance and output of your spinning operations. Proper evaluation of project scale will ensure that you select the appropriate tool, leading to better productivity and satisfaction in your metal spinning tasks.