Leave Your Message

Choosing the right metal spinning equipment is crucial for achieving optimal results in your projects, whether you are working on creating complex shapes or mass-producing simple components. As John Smith, a leading expert in the metal spinning industry, once stated, "The right machinery not only enhances productivity but also ensures precision and quality in metal forming." When selecting metal spinning equipment, factors such as the type of materials you will be using, the size of the projects, and your specific production needs must all be taken into account.

In today's competitive landscape, the importance of investing in high-quality metal spinning equipment cannot be overstated. The right choice can significantly reduce waste, improve turnaround time, and elevate the craftsmanship of your final products. Whether you're an established manufacturer or a new player in the field, understanding the technical aspects and operational capabilities of different machines will empower you to make informed decisions that align with your business goals. With a clear grasp of your requirements and the expert insights available, selecting the proper metal spinning equipment becomes a strategic step toward achieving excellence in your production processes.

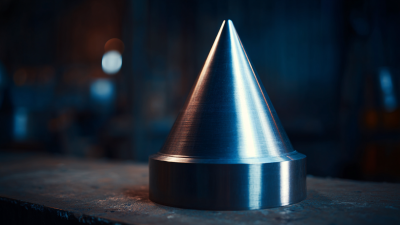

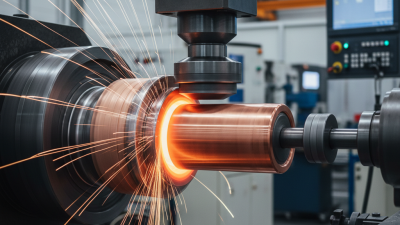

Metal spinning is a versatile manufacturing process that involves shaping metal into desired forms using a lathe. The primary mechanism involves rotating a metal disc or tube at high speed while a tool is pressed against the surface.

This technique allows for the creation of hollow shapes with varying wall thicknesses and is particularly advantageous in producing parts that require high precision and uniformity. According to industry reports, the global metal spinning market is expected to grow at a CAGR of 5.2% over the next five years, driven by increasing demand in sectors such as aerospace, automotive, and electronics.

Understanding the intricacies of metal spinning is crucial for selecting the right equipment for your projects. The process can be divided into several key stages: preparation, spinning, and finishing. During preparation, the metal workpiece is cleaned and cut to the desired dimensions. The spinning environment requires precise tooling and a lathe capable of maintaining consistent speeds to ensure quality results.

Additionally, reports suggest that investments in advanced CNC metal spinning equipment can yield efficiency gains of up to 30%, enhancing production capabilities while reducing waste. Thus, grasping the process of metal spinning not only aids in choosing suitable equipment but also significantly impacts the overall success of manufacturing operations.

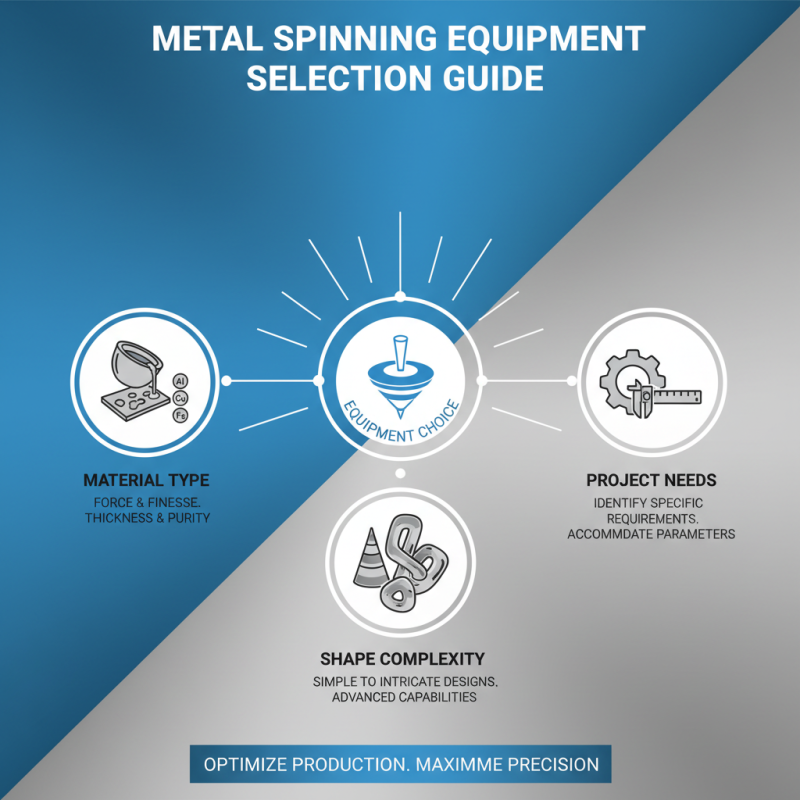

When selecting metal spinning equipment for your projects, it's crucial to start by identifying your specific needs. Consider the types of materials you will be working with, as different metals require varying levels of force and finesse during the spinning process. The thickness and purity of the material can also impact the choice of equipment, necessitating a machine that can accommodate your specific parameters. Additionally, evaluate the complexity of the shapes you intend to create; intricate designs may require more advanced capabilities in your spinning equipment.

Another key consideration is the scale of your production. If you are undertaking large-scale projects, investing in industrial-grade machinery may be more cost-effective in the long run, despite a higher initial expense. Conversely, for smaller or one-off projects, a more compact and versatile machine could suffice. Don't overlook the importance of ease of operation and maintenance—equipment that is user-friendly can reduce downtime and increase productivity. Finally, always factor in the availability of support and training resources to ensure you can maximize the efficiency of your chosen equipment.

When it comes to selecting the right metal spinning equipment for your projects, a detailed understanding of the various types available is crucial. Metal spinning can be divided primarily into manual, semi-automatic, and fully automatic equipment. According to a recent industry report by the Metal Forming Institute, manual spinning is often favored by artisans for its affordability and suitability for low-production runs, particularly in custom applications. This type of equipment provides extensive flexibility and allows for greater craftsmanship, though it may not meet the production speeds required for larger scale operations.

On the other hand, semi-automatic and fully automatic metal spinning machines are designed for higher efficiency and consistency, making them ideal for large-scale manufacturing. A comparative analysis reveals that semi-automatic machines can significantly reduce cycle times, achieving up to a 40% increase in productivity over manual methods. Fully automatic systems take this a step further, utilizing advanced robotics and precision controls to minimize human intervention and maximize output quality. Industry statistics indicate that companies employing fully automatic metal spinning equipment can reduce labor costs by as much as 30%, facilitating a more streamlined manufacturing process. Understanding these distinctions is essential for businesses looking to optimize their metal spinning operations effectively.

This chart compares various types of metal spinning equipment based on their advantages and applications for different projects.

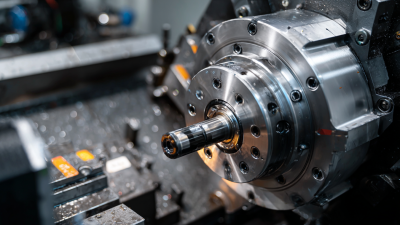

When selecting metal spinning equipment for your projects, evaluating equipment specifications is crucial to ensure optimal performance and efficiency. First, consider the machine's power and torque capabilities. A robust power output is essential for working with various metal thicknesses and types. High torque is particularly important for shaping thicker metals, as it determines the machine's ability to manipulate materials without causing undue stress or defects. Look for specifications that indicate the maximum diameter and thickness of metal that can be spun, as this will help you understand the versatility of the equipment.

Additionally, pay attention to the control systems integrated into the machinery. Modern metal spinning equipment often features advanced digital interfaces that allow for precise control over parameters like speed and pressure. This level of control is vital for achieving consistent results, especially when working with complex shapes or tight tolerances. Another important specification to consider is the machine's construction material and build quality, as these factors can significantly impact durability and maintenance needs, ultimately affecting long-term operational costs. By thoroughly assessing these specifications, you can choose the right metal spinning equipment that aligns with the demands of your projects.

| Specification | Description | Importance Level |

|---|---|---|

| Max Spinning Diameter | Maximum diameter the machine can spin | High |

| Motor Power | Power of the machine's motor | Medium |

| Material Compatibility | Types of metals that can be spun | High |

| Speed Range | The RPM range of the machine | Medium |

| Control System | Type of control (manual, CNC, etc.) | High |

| Safety Features | Safety mechanisms and protections integrated | High |

When considering budgeting for metal spinning equipment, it’s essential to evaluate the initial costs along with long-term operational expenses. According to a report by IBISWorld, the metal machining industry, which encompasses metal spinning, has seen a steady growth of approximately 3.5% annually over the past five years, highlighting the increasing demand for efficient machinery. Businesses should anticipate initial expenditures ranging from $20,000 to over $100,000 depending on the equipment's size, complexity, and capabilities. Higher-end models offer advanced features that may enhance productivity and reduce manual labor, thus creating potential savings in labor costs over time.

Furthermore, maintenance and operational costs significantly impact the overall budget. Research indicates that proper maintenance can prolong the life of metal spinning equipment by over 30%, making it a crucial aspect of financial planning. Companies can expect annual maintenance expenses to be around 10-15% of the initial purchase price, which necessitates including these figures in the overall budget calculation. Additionally, training personnel to operate the machinery effectively may require further investment, as skilled operators can contribute significantly to minimizing waste and optimizing production processes. By carefully considering these cost factors, manufacturers can make informed decisions that align with their project budgets and operational goals.