Leave Your Message

In today's competitive market, businesses must choose their machinery wisely. A Steel Spinning Machine offers unique advantages that can enhance production efficiency. These machines provide versatility for various metal forming applications. Their ability to create complex shapes from materials like aluminum and stainless steel is noteworthy.

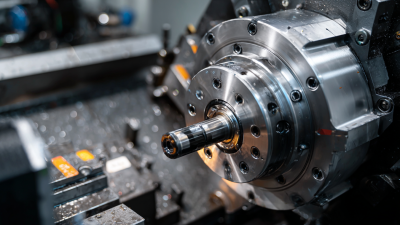

The precision that a Steel Spinning Machine achieves is remarkable. It ensures consistency in each produced item. This precision can lead to reduced waste and lower production costs. However, investing in such machinery requires careful consideration of your specific needs. Sometimes, businesses overlook the importance of training for operators, which can affect efficiency and safety.

Moreover, the initial investment in a Steel Spinning Machine may seem daunting. Yet, the long-term benefits often justify this expense. An evaluation of return on investment is crucial. An effective Steel Spinning Machine can significantly improve product quality and customer satisfaction when used correctly.

Steel spinning machines are crucial in various manufacturing processes. They transform flat metal sheets into intricate shapes. Understanding their operation helps businesses optimize production. A steel spinning machine uses rotational force to shape the material. The process is not only efficient but also cost-effective.

According to industry reports, the demand for metal spun products is expected to grow by 20% over the next five years. This growth highlights the significance of investing in high-quality spinning machines. However, not every machine is suited for all projects. Some businesses overlook the need for proper training. Insufficient skills can lead to wasted resources and time.

Material choice is critical in the spinning process. Steel offers strength and durability. However, it can be challenging to work with. Without the right techniques, inconsistencies may occur. Industry data shows a 15% error rate among untrained operators. Businesses must address these issues to remain competitive. Investing in training and the right tools is essential for success.

Steel spinning machines have become vital in the manufacturing sector. They offer unique advantages that make production more efficient. These machines can shape metal quickly and accurately. This precision reduces material waste. Businesses save both time and cost.

Using steel spinning machines allows for flexibility in design. You can create complex shapes that are difficult with traditional methods. For instance, you can produce conical, cylindrical, or elliptical forms without much hassle. This versatility appeals to various industries. Customization becomes easier, enabling companies to meet specific client needs.

**Tip:** When choosing a spinning machine, consider the size of the components you wish to create. Larger pieces may require a more robust machine. Efficiency is another factor. Assess the production speed and the machine's ability to handle different materials.

It's essential to evaluate your current processes. Are they draining your resources? Steel spinning machines can enhance workflow and reduce delays. However, they require skilled operators. Training can be a challenge but is crucial for maximizing machine capabilities. Embracing this technology can seem daunting, but the benefits often outweigh the initial hurdles.

| Advantage | Description | Impact on Business |

|---|---|---|

| Cost-Effective | Steel spinning machines reduce material waste and lower production costs. | Increased profit margins and reduced overhead. |

| Versatility | Can manufacture a wide range of shapes and sizes for various applications. | Ability to cater to diverse customer needs and markets. |

| Quality & Precision | Produces high-quality parts with tight tolerances. | Enhances credibility and reduces rework costs. |

| Energy Efficiency | Modern machines consume less energy compared to traditional methods. | Lower utility costs and improved sustainability. |

| Fast Production | Shorter lead times for producing complex shapes. | Enhanced customer satisfaction and feedback. |

When selecting a steel spinning machine, certain features are crucial. Look for machines with adjustable speed settings. Speed variability enhances precision across different projects. A 2023 industry report indicates that machines with variable speed can increase production efficiency by up to 30%. This adaptability is vital for tailoring to specific design requirements.

Another important feature is a robust frame. A sturdy machine minimizes vibrations. Excess vibrations can lead to inaccuracies, wasting materials and time. A study from the Steel Fabrication Institute notes that at least 25% of production errors arise from equipment instability. This isn’t negligible; it’s a significant area to address.

Finally, ease of operation should not be overlooked. Machines with intuitive controls are more user-friendly. Workers require less training, saving both time and costs. In this competitive market, efficiency matters. In conclusion, selecting a machine with these features can significantly impact your business operations. However, it’s essential to assess the actual effectiveness of these claims before making a purchase.

When considering fabrication methods, steel spinning offers unique advantages. Unlike traditional machining, steel spinning is efficient for producing symmetrical shapes. This technique uses a rotating blank, shaped by a tool against a mold. The result is consistent and often requires less material.

Compared to methods like welding or cutting, steel spinning generates less waste. It allows for thicker materials while maintaining strength. However, mastering steel spinning requires skill. Precision is key, and mistakes can lead to significant losses. Operators must understand the nuances of different materials.

While steel spinning is versatile, it might not suit every application. Complex designs can pose challenges. Exploration into other methods remains necessary. Balancing the pros and cons is vital for informed decisions.

Steel spinning machines have transformed various industries. For example, in the aerospace sector, these machines create lightweight, durable components essential for modern aircraft. Recent industry reports highlight that steel spinning improves the efficiency of manufacturing. In a study by the International Association of Machinists, 78% of firms using spinning technology reported reduced material waste.

Automotive manufacturers are also benefiting. Steel spinning allows for the production of complex shapes, which can be crafted quickly. A case study by a leading engineering group revealed a 30% decrease in production time when using steel spinning instead of traditional methods. This clearly shows how innovation in machinery can result in significant cost savings.

Tips: When considering a steel spinning machine, assess your production needs carefully. Evaluate the types of shapes and sizes you need. Not having clear specifications can lead to unnecessary expenditures.

It is important to note that not every project fits this technology perfectly. Some designs may still require traditional manufacturing processes. Reflecting on this, keep an open mind to hybrid solutions. Being flexible in your approach can lead to better outcomes and more innovative products.

This chart illustrates the monthly production of various components using steel spinning machines across different industries. The data highlights the versatility and efficiency of steel spinning technology in producing high-quality parts for automotive, aerospace, industrial equipment, custom fabrication, and home decor applications.