Leave Your Message

Choosing the right Flange Flanging Machine is a critical decision for industries that rely on precise and efficient flanging processes. With a variety of options available, each with unique features and capabilities, the task can be daunting for operators and procurement specialists alike. Understanding your specific needs, such as the types of flanges you work with, production volumes, and material specifications, is essential to select a machine that will enhance your operational efficiency and maintain product quality.

In this guide, we will explore the key considerations when choosing a Flange Flanging Machine. From understanding the different types of machines available, including hydraulic, mechanical, and portable options, to evaluating aspects such as ease of use, maintenance requirements, and cost-effectiveness, we aim to equip you with the knowledge necessary for making an informed decision. Additionally, we will discuss how technological advancements are shaping the industry and what features to look for in a modern flanging machine to ensure you remain competitive in the market.

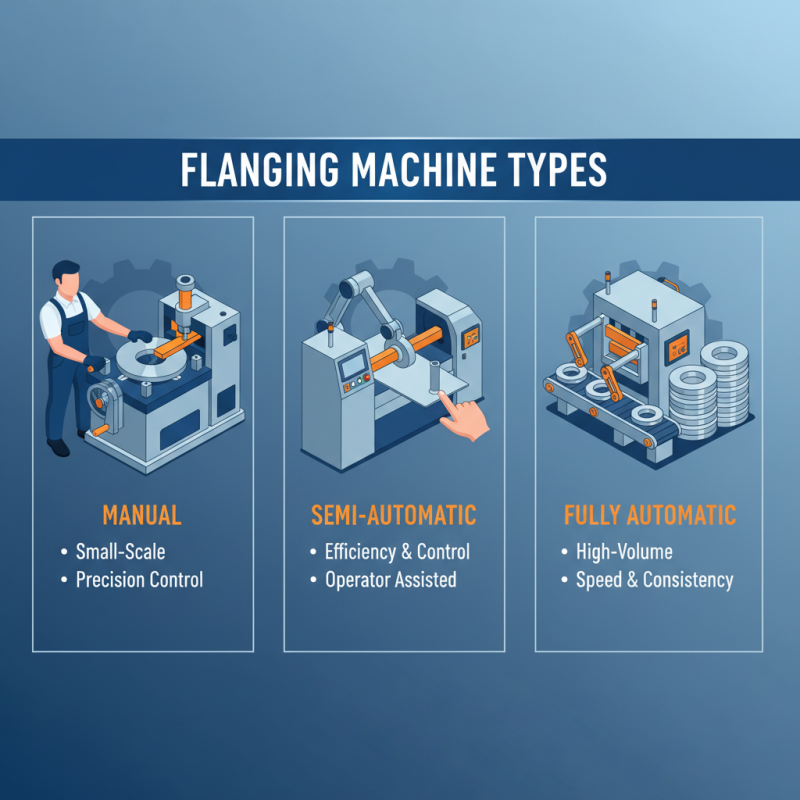

When selecting a flanging machine, it's crucial to understand the different types available on the market. Flanging machines can generally be categorized into manual, semi-automatic, and fully automatic types. Manual machines require more operator involvement, making them suitable for small-scale operations where precision and control are essential. Semi-automatic machines offer a balance between efficiency and manual control, providing assistance while still allowing for operator input. Fully automatic machines, on the other hand, are ideal for high-volume production where speed and consistency are paramount.

Tips: One important consideration when choosing a flanging machine is to assess the material types you'll be working with. Different machines are designed to handle specific materials, so ensure that your choice aligns with the requirements of your projects. Additionally, factor in the thickness of the materials, as some machines may not accommodate heavier gauges effectively.

Another key aspect to keep in mind is the machine’s adaptability to various flanging techniques. Some machines come equipped with interchangeable tooling, allowing for greater versatility. This adaptability can be particularly beneficial if your production needs change over time. Always check the specifications and capabilities of the machine you’re interested in to ensure it meets your operational requirements.

When selecting the right flanging machine for your needs, understanding the key specifications is crucial. First and foremost, consider the capacity of the machine, which typically ranges from 0.5 to 2 inches in thickness and can handle varying diameters. According to industry reports from the American Society of Mechanical Engineers (ASME), machines with higher tonnage capability are essential for working with thicker materials, ensuring precision and quality in the final product. A flanging machine should ideally accommodate different sizes and types of flanges to enhance versatility in projects.

Another critical specification is the material construction of the machine. Machines made from high-grade steel provide improved durability and performance over time, especially when dealing with high-volume production. Recent surveys indicate that businesses prioritizing robust construction are likely to see a reduction in maintenance costs by up to 30%, enhancing overall productivity. Furthermore, the speed and efficiency of the flanging process, often measured in revolutions per minute (RPM), can significantly impact production rates. For example, a machine operating at higher RPMs can increase output by approximately 25%, making it a vital consideration for manufacturers aiming to meet tight deadlines.

In conclusion, focusing on capacity, material construction, and operational efficiency will guide you in selecting a flanging machine that satisfies both current demands and future growth. Understanding these specifications ensures that you invest in a machine that aligns with your production goals, ultimately leading to improved operational success.

When selecting a flanging machine, it's crucial to assess your material and thickness requirements carefully. Different materials respond differently to the flanging process, and understanding their properties can help you choose a machine that meets your specific needs. For instance, softer materials like aluminum may require less force to form, whereas harder materials such as stainless steel may necessitate a machine capable of exerting higher pressure. Knowing the type of material will help determine the machine’s compatibility and efficiency, thereby ensuring a successful flanging operation.

In addition to the material type, the thickness of the materials being processed significantly influences the choice of flanging machine. Thicker materials often require specialized machines that offer greater power and control to achieve precise flanging results. Moreover, the thickness can dictate the machine's tooling requirements, which are essential for maintaining accuracy and surface integrity during the flanging process. By evaluating both material and thickness, manufacturers can select a flanging machine that not only meets their production requirements but also enhances the overall quality of the finished product.

When choosing a flange flanging machine, it’s crucial to evaluate your operational needs and the machine's capacity. Start by assessing the types of flanges you will be working with. Consider their sizes, materials, and the required flange profiles. This will help you determine the machine specifications, such as the maximum diameter it can handle and the bending force required for the materials you intend to work with. Also, think about your production volume; a machine designed for higher throughput will benefit businesses with larger production demands.

**Tips:** Always consult the manufacturer’s guidelines or your technical team about potential production bottlenecks and ensure the machine’s features align with your operational workflow. Additionally, contemplate the ease of operation and maintenance. A machine with user-friendly controls can reduce training time and help in swift troubleshooting.

Furthermore, consider the future scalability of your operations. If you foresee an increase in production or a diversification of your product range, choose a machine that offers flexibility and can be easily upgraded. This foresight can save time and resources in the long run.

**Tips:** Keep an eye out for machines that support add-ons or modular upgrades, allowing you to adapt to changing production needs without the need for an entirely new machine.

| Machine Type | Material Compatibility | Max Flanging Diameter (inches) | Operational Speed (RPM) | Weight (lbs) | Power Requirement (HP) |

|---|---|---|---|---|---|

| Hydraulic Flanging Machine | Steel, Aluminum | 24 | 20 | 2500 | 15 |

| Electric Flanging Machine | Stainless Steel, Brass | 36 | 30 | 3200 | 20 |

| Bench Flanging Machine | Aluminum, Copper | 12 | 40 | 800 | 5 |

| Portable Flanging Machine | Carbon Steel, Alloy Steel | 18 | 25 | 1500 | 10 |

When selecting a flanging machine, budget considerations play a pivotal role in making the right choice. The initial acquisition cost of the equipment is just one aspect of the overall budget; organizations must also account for maintenance, operational efficiency, and the longevity of the machine. Cheaper options may seem attractive upfront, but they often come with hidden costs related to repairs and downtime, which can significantly offset savings. Therefore, it's essential to evaluate the total cost of ownership rather than just the purchase price.

In addition to the acquisition costs, it is also important to consider the machine's energy efficiency and productivity rate. A more expensive, high-quality flanging machine that operates efficiently and requires less frequent maintenance can prove to be more cost-effective in the long run. Investing in technology that enhances productivity not only helps reduce labor costs but also improves throughput, making it easier to meet production demands. Ultimately, a careful assessment of both the initial investment and the potential long-term savings will help manufacturers choose the flanging machine that best aligns with their financial capabilities and operational needs.