Leave Your Message

In the world of manufacturing, choosing the right Hydraulic Flanging Machine can significantly impact productivity and efficiency. Industry reports indicate that flanging processes have seen a 30% increase in demand over the past five years. As the need for precision in metal fabrication grows, understanding what to look for is essential. Expert James Miller states, "Selecting the correct machine isn't just about specifications; it's about aligning capabilities with project needs."

Optimal performance and reliability hinge on various factors, including machine specifications, the complexity of tasks, and budget considerations. The absence of thorough research can lead to costly mistakes. It’s not merely a matter of buying the latest model but understanding suitability for specific applications.

Moreover, the market is inundated with options, which can overwhelm buyers. Each Hydraulic Flanging Machine has unique features that cater to different needs. Thus, being informed is crucial. A careful evaluation of your requirements can lead to better decision-making and improved outcomes in your operations.

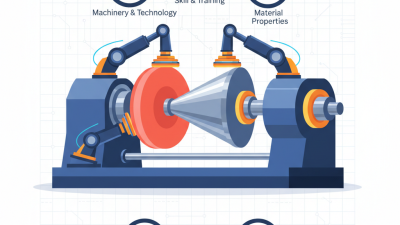

When selecting a hydraulic flanging machine, understanding the various types available is key. These machines are categorized mainly into three types: manual, semi-automatic, and fully automatic. Each type serves different production needs and operational skill levels. For example, manual machines require more hands-on attention but are often more affordable. Semi-automatic machines strike a balance, offering improved efficiency. Fully automatic machines are the most advanced, facilitating high-volume production with minimal operator intervention.

According to industry reports, fully automatic machines can increase production rates by up to 25%. They excel in consistent flanging outcomes, making them suitable for large-scale operations. However, their higher upfront cost might not be suitable for smaller businesses.

Tip: Work closely with your production team to assess which type will optimize your workflow. Gather feedback on current challenges to make an informed decision.

Flexibility is another consideration. Different projects may require varying levels of precision and speed. For instance, a manual flanging machine may struggle with tight tolerances. Conversely, fully automatic machines can sometimes be overkill for smaller tasks. Continuous evaluation of your operational needs can prevent costly missteps.

Tip: Research and consult multiple sources before finalizing your choice. It’s essential to ensure the machine meets your unique demands while providing room for future growth.

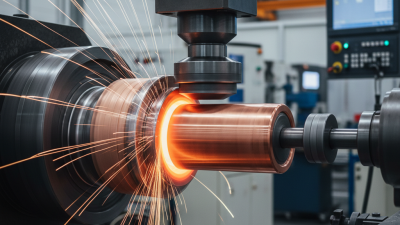

When selecting a hydraulic flanging machine, several key factors must be considered. The machine's capacity is crucial. It should handle the thickness and type of material you plan to work with. According to industry standards, flanging machines should accommodate materials ranging from mild steel to stainless steel. The bending angle you require can also influence your choice. Ensure that the machine can efficiently produce the angles specified in your projects.

Another important factor is the machine's stability. Robust construction enhances the machine's longevity and performance. A well-built hydraulic flanging machine will minimize vibration during operation, leading to better accuracy. Industry reports indicate that machines with heavier frames experience less distortion, ensuring consistent results. Look for models that offer adjustable parameters for different flange types. Customization can improve your workflow significantly.

Tips: Always test a machine before purchasing. This ensures it meets your specific needs and expectations. Check customer reviews and industry feedback. Pay attention to energy efficiency ratings. A machine that consumes less power can save costs over time. Sometimes, less expensive options may lack essential features. Do your research thoroughly.

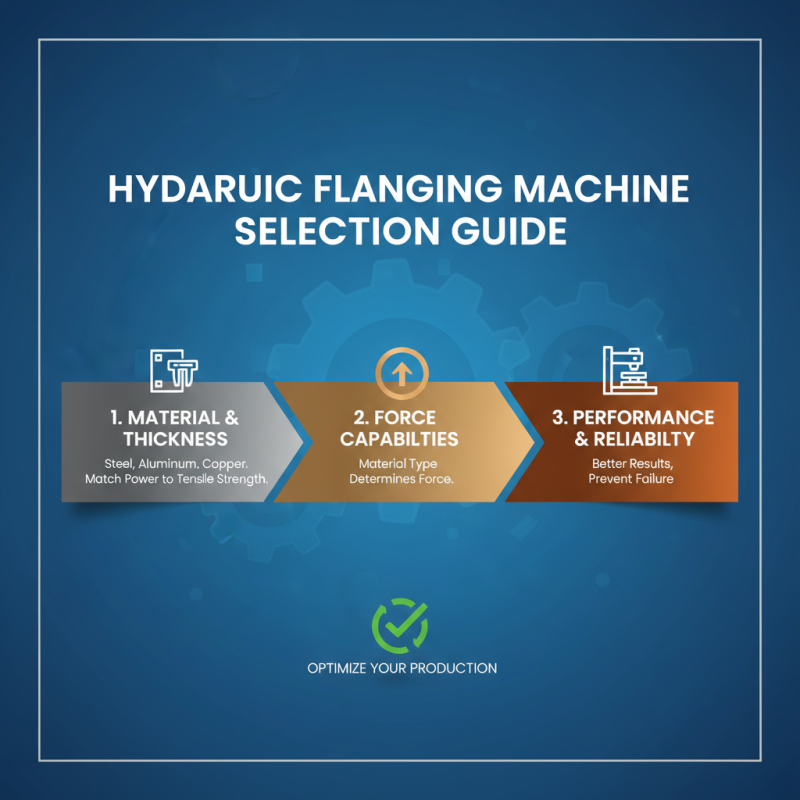

Choosing the right hydraulic flanging machine starts with assessing your material and thickness. The type of material directly influences the machine’s specifications. Steel, aluminum, and copper require different force capabilities. When working with thicker materials, it's crucial to match the machine’s power to the material’s tensile strength. This consideration will lead to better results and prevent equipment failure.

Thickness varies widely among applications. For instance, thin sheets bend easily, while thicker plates need more force. Many seem to overlook the implications of thickness when selecting a machine. A machine too weak will struggle, causing poor flanging quality. Conversely, a machine that is overly powerful may damage thinner materials.

Take a moment to review your specific requirements. Consider the range of thickness you typically handle. You might find that your current machine isn't ideal for your needs. Reflecting on past projects can reveal gaps in your equipment choice. This process is crucial for achieving optimal performance and avoiding costly mistakes.

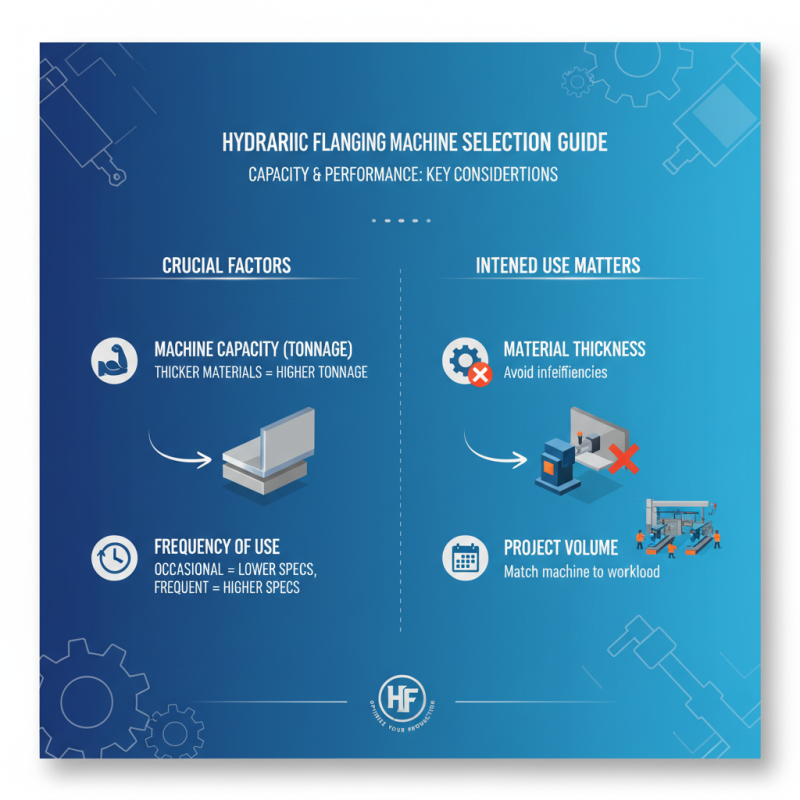

When selecting a hydraulic flanging machine, machine capacity and performance specifications are crucial. Understanding the intended use can help. For example, if you plan to work with thick materials, you’ll need a machine that can handle higher tonnage. A lower capacity might struggle, leading to inefficiencies. Additionally, consider the frequency of use. A machine meant for occasional projects may not need high specifications.

Performance specifications include speed and accuracy. Machines that operate too slowly can hinder production. Accuracy is vital for ensuring proper fits. If the machine struggles with these aspects, it could lead to costly mistakes. Look for machines with reliable feedback on performance metrics. Yet, be cautious of features that seem too advanced for your operation. Sometimes, simplicity is better.

Evaluate the dimensions and design of the machine, too. A bulky flanging machine might consume valuable shop space. However, smaller models could compromise on power. Think about energy consumption and maintenance needs as well. These factors often get overlooked. It's essential to balance between capability and practicality. Reflecting on these points can ensure you make a more informed choice.

Budgeting for a hydraulic flanging machine goes beyond the initial purchase price. Typically, these machines range from $20,000 to $100,000. An organization needs to consider its budget for maintenance. Industry reports indicate that maintenance costs can account for 10-15% of the initial investment annually. This means planning for regular services is essential. Unexpected breakdowns may lead to steep repair bills.

Repairing a hydraulic flanging machine often costs about $2,500 to $5,000 per incident. It can drain resources quickly if not anticipated. Furthermore, downtime due to repairs can result in lost productivity and revenue. Investing in a reliable machine may save money on repairs, but upfront costs can be daunting. It's a delicate balance.

Additionally, training for operators and technicians adds to the overall budget. Comprehensive training can cost an extra $1,000 to $3,000 per person. Knowledgeable staff can prevent common mistakes. Yet, not all companies allocate enough for this crucial element. Failure to budget accordingly may lead to costly operational issues. Balancing initial costs versus ongoing expenses is crucial for long-term success.