Leave Your Message

In the dynamic world of metal fabrication, selecting the right Hydraulic Flanging Machine is crucial for optimizing efficiency and ensuring high-quality results. According to industry expert Dr. Mark Thompson, a renowned engineer in hydraulic systems, "Choosing the right Hydraulic Flanging Machine can significantly impact your production capabilities and overall project success." With various models and features on the market, it can be overwhelming for businesses to navigate their options.

When it comes to Hydraulic Flanging Machines, the decision-making process should involve a thorough understanding of your specific needs and the machine's capabilities. Factors such as the thickness of the materials being processed, the required production speed, and the complexity of the flanging operations are essential considerations. By taking the time to assess these criteria, manufacturers can invest in a Hydraulic Flanging Machine that not only meets their current demands but also adapts to future projects, ensuring long-term productivity and sustainability.

Hydraulic flanging machines are essential tools in various industrial applications, primarily used for creating flanges, which are vital for joining pipes, vessels, and other components. These machines operate by utilizing hydraulic pressure to deform metal sheets or pipes, producing precise and uniform flanged surfaces. Understanding their applications is crucial for industries such as shipbuilding, manufacturing, and construction, where the integrity of joints is paramount for safety and functionality.

The versatility of hydraulic flanging machines allows them to be employed in numerous settings. They can handle a range of materials, including steel, aluminum, and even certain plastics, making them applicable in both light and heavy-duty projects. Additionally, these machines can accommodate different flange types and sizes, allowing for customization based on specific project requirements. Their capacity to produce consistent results enhances productivity and ensures that components can withstand the demands of their operational environments. As such, recognizing the unique advantages of hydraulic flanging machines enables businesses to effectively choose the right equipment to meet their specific needs.

When selecting a hydraulic flanging machine, it’s essential to focus on several key features that align with your operational needs. First and foremost, consider the machine's capacity and the range of materials it can handle. A good flanging machine should accommodate various thicknesses and types of material, whether you're working with steel, aluminum, or other metals. The tonnage capacity is crucial as it determines the maximum force the machine can exert, influencing both efficiency and the quality of the finished flange.

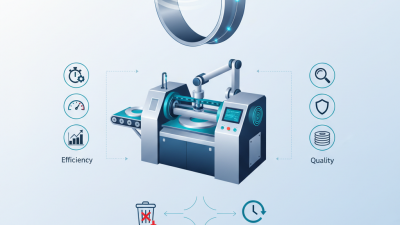

In addition to capacity, examine the machine’s control system and functionality. Modern hydraulic flanging machines often come with advanced control interfaces that allow for precise adjustments and settings. Look for features such as programmable settings, which enable users to save specific parameters for consistent results across different projects. Additionally, hydraulic systems should be designed for easy maintenance and durability, ensuring the machine remains efficient over time with minimal downtime. Overall, these considerations will help ensure that you choose a hydraulic flanging machine that meets your production demands effectively.

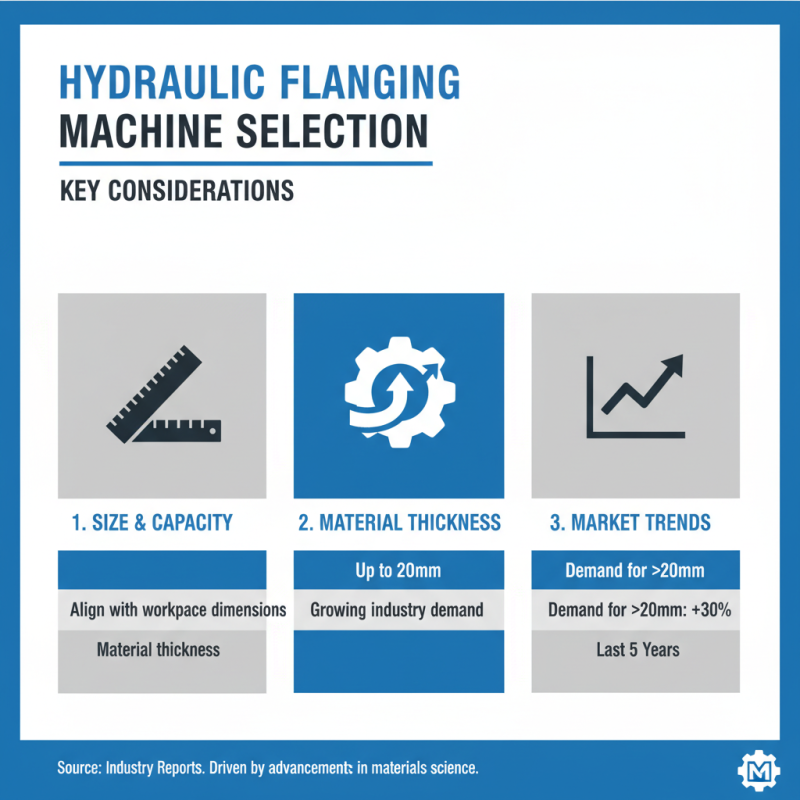

When selecting a hydraulic flanging machine, evaluating the size and capacity requirements of your projects is crucial. The dimensions of the machine must align with the specifications of the workpieces you intend to process, as well as the maximum thickness of materials required. According to industry reports, the demand for hydraulic flanging machines capable of handling materials up to 20mm thick has increased by over 30% in the last five years, driven by advancements in material science and engineering applications.

Moreover, the capacity of the hydraulic flanging machine is not only determined by the maximum flat size it can handle but also by its tonnage. Machines with higher tonnage ratings usually provide more efficient and precise flanging capabilities, allowing for the production of complex shapes and designs. Recent studies indicate that machines with a capacity range of 50 to 300 tons are becoming industry standards due to their versatility in both small-scale and large-scale production environments. Careful assessment of these parameters will ensure that the chosen machine fits your operational needs, thereby enhancing productivity and efficiency in your manufacturing processes.

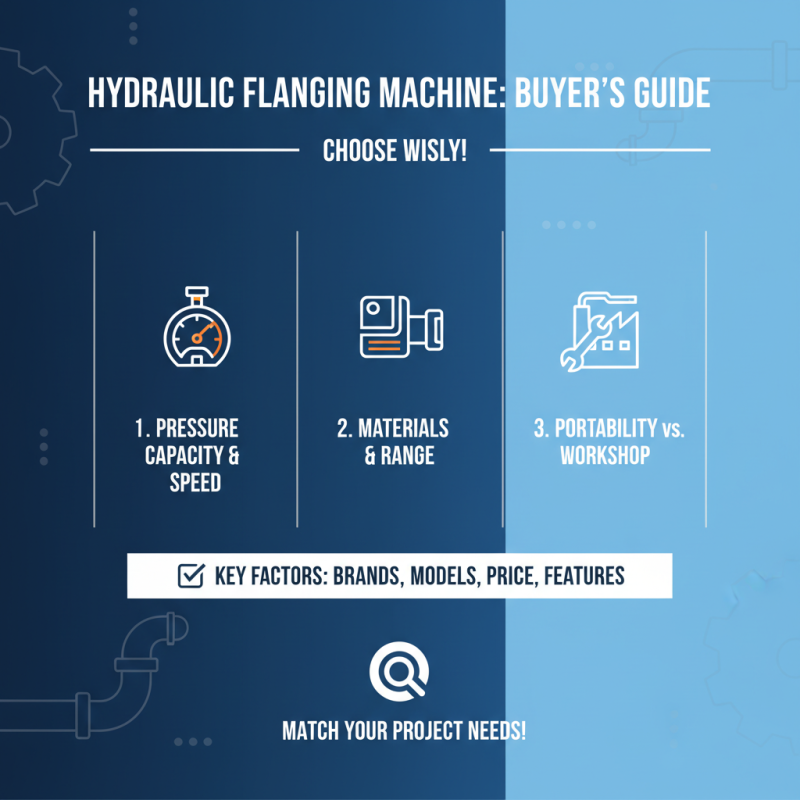

When selecting a hydraulic flanging machine, it’s essential to compare different brands and models based on your specific needs. Each manufacturer offers various specifications, features, and price ranges. Factors such as pressure capacity, flanging speed, and the range of materials that can be processed should guide your comparison. Some models excel in portability, making them suitable for fieldwork, while others are built for heavy-duty operations in a workshop setting. Understanding the operational requirements of your projects will help you narrow down the options effectively.

Additionally, it's important to consider user feedback and reviews when evaluating different hydraulic flanging machines. Many models will vary in terms of ease of use, maintenance needs, and reliability over time. Comparing available customer experiences can provide valuable insight into how well each machine performs in real-world scenarios. Pay attention to warranty offerings and customer support services, as they can greatly influence your long-term satisfaction with the equipment. By thoroughly comparing these aspects, you can make a well-informed decision that aligns with your operational demands and budget constraints.

When considering the purchase of a hydraulic flanging machine, it is crucial to perform a thorough budgeting and cost analysis to ensure your investment aligns with your operational needs. According to industry reports, the initial cost of hydraulic flanging machines can range from $5,000 to over $50,000, depending on factors such as capacity, features, and manufacturer. Understanding your specific requirements will help you narrow down your choices and avoid overspending on unnecessary features.

One important tip is to create a detailed list of your needs and potential use cases for the machine. Consider factors such as the thickness of materials you'll be working with, the types of flanges you will produce, and any additional features that may improve productivity. A study by the Manufacturing Industry Institute highlights that companies that invest time in this initial analysis often see a return on investment (ROI) of 20% or more within the first year of usage.

Another useful strategy is to account for ongoing operational costs related to maintenance, power consumption, and labor. These factors can significantly impact the total cost of ownership over time. According to a survey from the National Association of Manufacturers, approximately 70% of manufacturers report that lifecycle costs are a major consideration when making equipment purchasing decisions. By carefully evaluating both initial expenses and ongoing costs, you can make a well-informed decision that supports your budget and operational goals.