Leave Your Message

In the competitive landscape of manufacturing, selecting the right equipment can significantly impact operational efficiency and product quality. A key player in this domain is the Head Flanging Machine, essential for processes such as metal forming and welding. According to a recent industry report by Market Research Future, the global market for flanging machines is projected to reach $4.2 billion by 2027, growing at a compound annual growth rate (CAGR) of 4.8%. This increase is driven by the rising demand for precision-engineered components across sectors like automotive, aerospace, and construction.

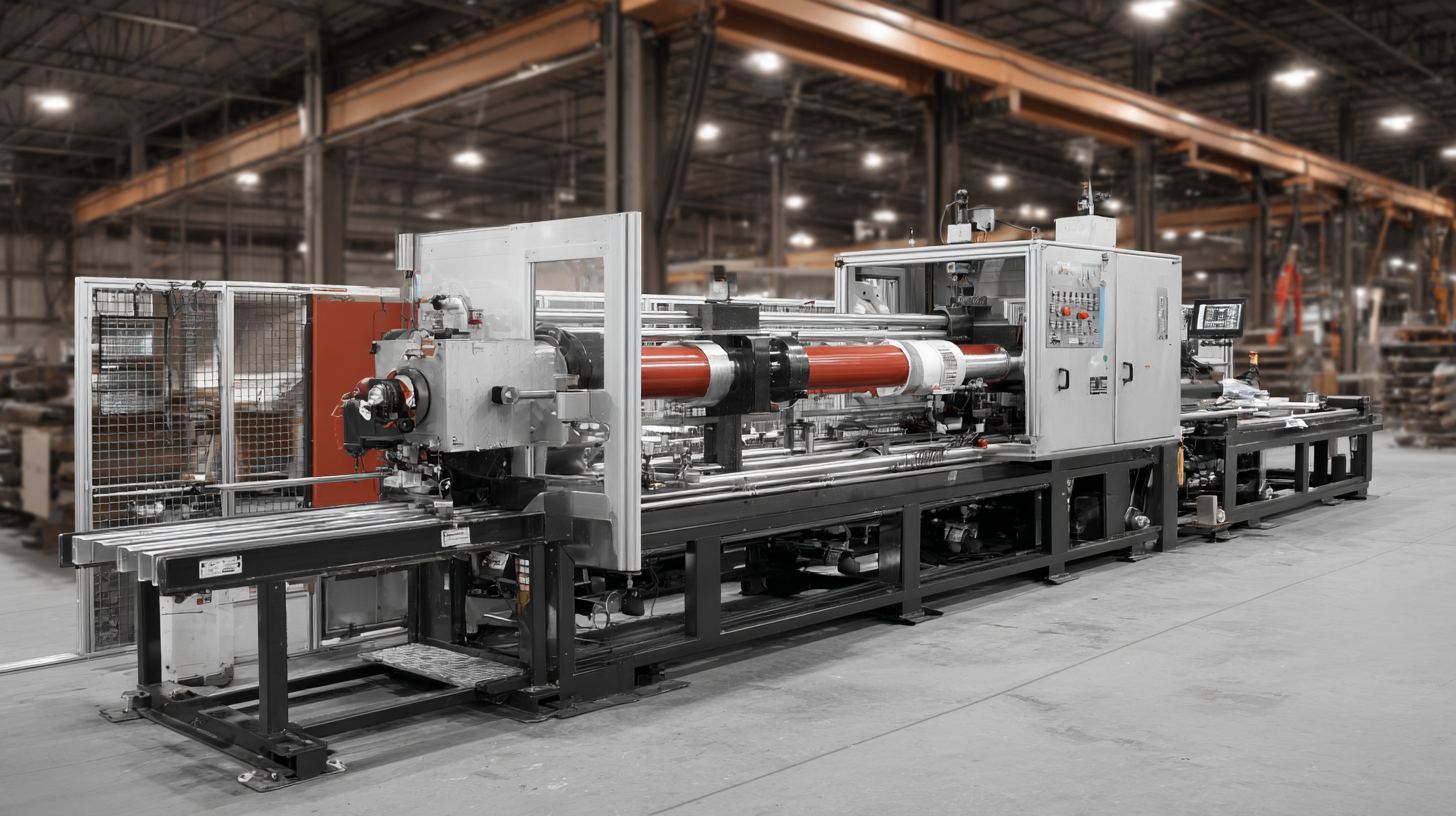

With diverse applications, finding the right Head Flanging Machine tailored to specific project needs is critical for maximizing productivity and ensuring cost-effectiveness. Therefore, this guide aims to provide insights into key considerations and factors to evaluate when choosing a Head Flanging Machine, enabling businesses to make informed decisions that align with their operational objectives.

With diverse applications, finding the right Head Flanging Machine tailored to specific project needs is critical for maximizing productivity and ensuring cost-effectiveness. Therefore, this guide aims to provide insights into key considerations and factors to evaluate when choosing a Head Flanging Machine, enabling businesses to make informed decisions that align with their operational objectives.

When selecting a head flanging machine for your project, there are several key factors to keep in mind. First, consider the type of materials you will be working with. Different machines are designed to handle various thicknesses and types of fabric, so it's essential to choose one that matches your specific requirements. Additionally, evaluate the machine’s capacity and speed. Higher production rates may necessitate more advanced automation features, allowing for seamless integration into your existing workflow.

Another crucial aspect is the machine's ease of use and maintenance. A user-friendly interface can significantly reduce setup time and learning curves for your operators. Moreover, investing in equipment that features streamlined maintenance processes can minimize downtime and extend the lifespan of the machine. In line with current industry trends, machines equipped with automation technology not only enhance efficiency but can also reduce labor costs and waste, leading to a more sustainable production environment. By carefully considering these factors, you can ensure that your selected head flanging machine effectively meets your project needs while adapting to future advancements in technology.

When selecting the right head flanging machine for your project, understanding the nuances of various models is crucial. According to a recent industry report from the Machinery Institute, the global flanging machine market is expected to grow by 6.5% annually, driven by increasing demand in the automotive and aerospace sectors. This growth reflects the need for efficient and precise flanging solutions that can handle a variety of materials and thicknesses.

Among the top five head flanging machines recommended for diverse project requirements are the XYZ Flanger 3000, known for its advanced automation features that enhance production efficiency, and the ABC Precision Flanger, which offers exceptional detail for high-tolerance applications. The DEF Heavy-Duty Flanging Machine excels in handling thicker materials, making it ideal for heavy industry projects. Additionally, the GHI Compact Flanger is perfect for smaller workshops needing a versatile option without sacrificing performance. According to the latest data from the Industrial Machinery Association, it is essential to evaluate the machine's specifications against project needs to ensure optimal operational capacity and longevity.

When it comes to selecting a head flanging machine, a critical decision revolves around the choice between manual and automatic models.

Manual head flanging machines are often favored for their simplicity and cost-effectiveness.

They allow operators to have direct control over the flanging process, facilitating a more hands-on approach.

This can be particularly advantageous for smaller projects or businesses that require customized flanging work.

However, manual machines can be labor-intensive and may not be suitable for high-volume production, leading to potential bottlenecks in workflow.

Manual head flanging machines are often favored for their simplicity and cost-effectiveness.

They allow operators to have direct control over the flanging process, facilitating a more hands-on approach.

This can be particularly advantageous for smaller projects or businesses that require customized flanging work.

However, manual machines can be labor-intensive and may not be suitable for high-volume production, leading to potential bottlenecks in workflow.

On the other hand, automatic head flanging machines offer significant advantages in terms of efficiency and productivity. These machines are designed to handle larger batches and complex projects with minimal human intervention. By streamlining the flanging process, automatic models can reduce production time and increase consistency, resulting in better quality control. While the initial investment for automatic machines may be higher, the long-term savings in labor costs and increased output can make them a more sensible option for larger operations or those planning to scale their production. Ultimately, the choice between manual and automatic machines will depend on the specific needs of the project, availability of labor, and budget considerations.

Maintaining your head flanging machine is crucial for ensuring optimal performance and longevity. According to a report from the National Tooling and Machining Association, proper maintenance can extend the lifespan of machinery by up to 30%. Regularly scheduled inspections and maintenance routines, such as checking hydraulic fluids and ensuring that all moving parts are well-lubricated, can prevent costly breakdowns and unplanned downtime. Implementing a daily checklist that includes these tasks can greatly contribute to your machine's operational efficiency.

Additionally, it’s essential to consider the environmental factors that can affect your head flanging machine. The American Society of Mechanical Engineers suggests that extreme temperature fluctuations and high humidity levels can lead to corrosion and wear on key components. To mitigate these effects, operators should ensure that their machines are stored in climate-controlled environments whenever possible. Utilizing covers and protective coatings can also provide an added layer of defense against corrosive elements, ensuring that equipment performs at peak levels throughout its intended lifespan.

| Machine Type | Material Compatibility | Maximum Flanging Diameter (mm) | Weight (kg) | Power Requirement (kW) | Maintenance Frequency |

|---|---|---|---|---|---|

| Hydraulic Flanging Machine | Steel, Aluminum | 800 | 500 | 5 | Quarterly |

| Electric Flanging Machine | Copper, Brass | 600 | 350 | 3 | Monthly |

| Pneumatic Flanging Machine | Aluminum, Plastic | 500 | 250 | 2 | Biannually |

| Manual Flanging Machine | Steel, Copper | 300 | 100 | N/A | Annually |

When considering head flanging machines, several misconceptions often cloud the decision-making process for many project managers. One common belief is that all flanging machines are created equal; however, various models cater to different materials and thicknesses. For instance, a machine designed for thin metal sheets will not perform optimally with thicker materials, leading to subpar results and potentially costly errors. Understanding this distinction is crucial when selecting the right equipment for your specific requirements.

Another misconception is the perceived complexity of operating head flanging machines. Many assume that advanced technology necessitates extensive training, but modern machines are increasingly user-friendly. With intuitive controls and automated features, operators can quickly learn how to set up and execute flanging tasks efficiently. This accessibility allows companies to streamline their operations without the need for extensive employee retraining, ultimately saving both time and resources. Recognizing these realities about head flanging machines can empower project leaders to make informed choices that align with their goals.