Leave Your Message

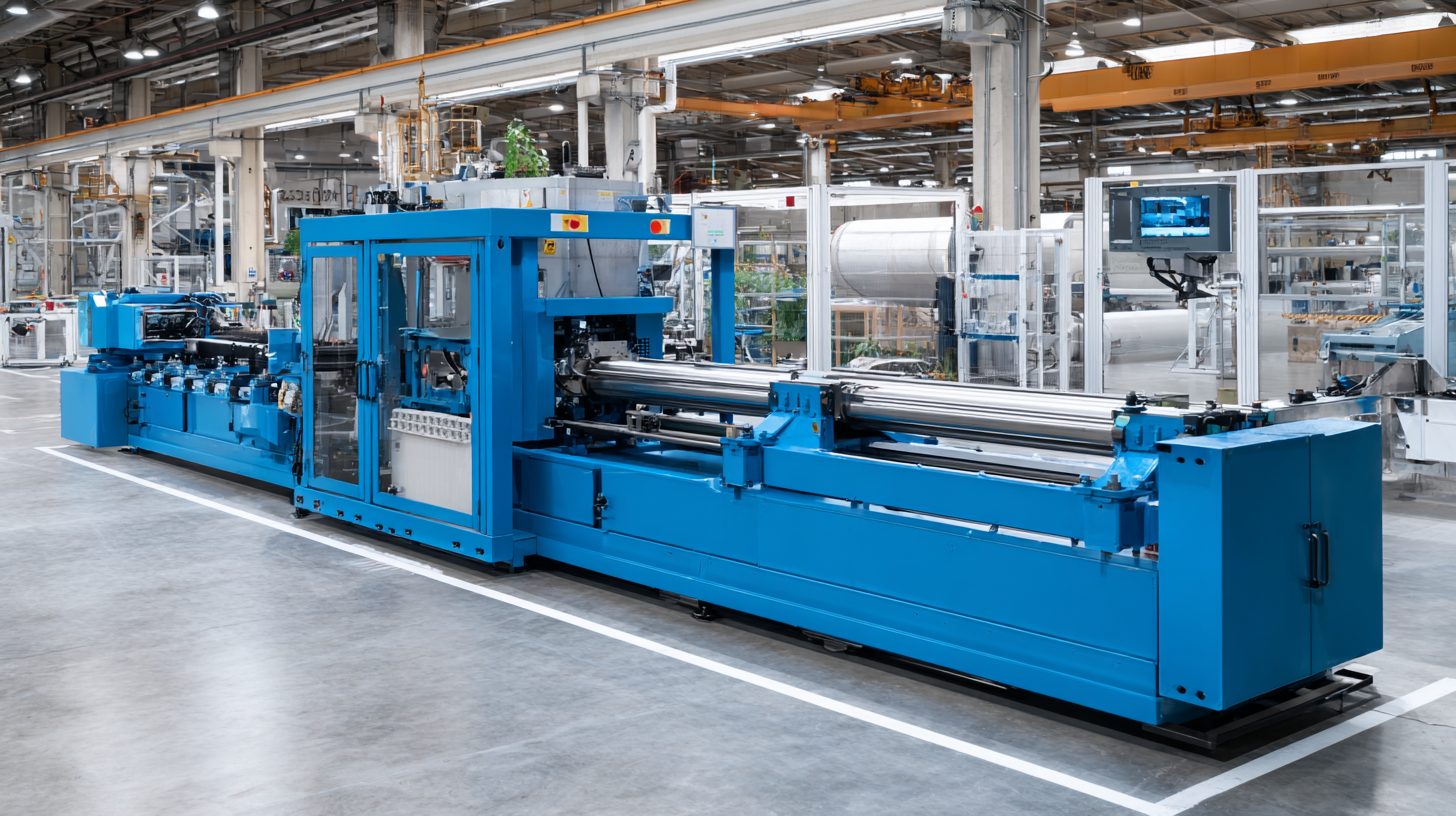

When it comes to selecting the perfect Head Flanging Machine for your production needs, the task can seem daunting. With the myriad of options available in the market, making an informed decision is crucial. According to industry expert, John Smith, a renowned authority in metal forming technologies, "Choosing the right Head Flanging Machine is vital to ensuring not only efficiency in production but also the quality of the final output." His insights underscore the importance of understanding the key features and specifications that align with specific production requirements.

As the demand for precision and efficiency increases, manufacturers must pay close attention to the technology and capabilities of Head Flanging Machines. Factors such as machine performance, ease of operation, and maintenance support play crucial roles in this decision-making process. By following essential tips and best practices, manufacturers can optimize their selection process, ultimately enhancing productivity and reducing operational costs. In this article, we will explore the top ten tips that will guide you in choosing the right Head Flanging Machine efficiently, ensuring you make a well-informed investment that meets your production goals.

When selecting a head flanging machine, several key factors must be considered to ensure it meets your production needs efficiently. First, evaluate the machine's production capacity, which should align with your project demands. If you require high-volume output, opt for machines designed to handle larger batches, while also considering the speed of operation to maximize efficiency. Additionally, compatibility with various materials is crucial; choose a machine that can effectively work with the types of metals you frequently use, as this will enhance versatility and reduce downtime.

Another essential factor is the level of automation. Automated head flanging machines can significantly increase productivity and reduce the likelihood of human error. Look for features like programmable settings and real-time monitoring to ensure consistent quality. Furthermore, maintenance requirements should not be overlooked. Choosing a machine with easily accessible parts can save time and reduce operational costs over the long term. By carefully assessing these factors, you can select a head flanging machine that not only meets your current requirements but also adapts to your future production needs.

When selecting a head flanging machine, it is crucial to understand the different types available on the market. The primary categories include mechanical, hydraulic, and fully automated machines, each designed to cater to specific production needs. According to a recent industry report, the demand for automated machines has surged by 25% over the last year, driven by their efficiency in reducing labor costs and minimizing material wastage. Fully automated flanging machines, in particular, can enhance production speed by as much as 40%, making them an attractive option for manufacturers looking to optimize their operations.

Moreover, advancements in technology have led to significant improvements in machine design and functionality. Industry experts note that modern flanging machines incorporate features such as real-time monitoring and precision control systems, which further enhance their performance. Automation has been a game changer; it not only streamlines production processes but also allows manufacturers to achieve more complex designs with greater accuracy. As the market continues to evolve, understanding these different machine types and their capabilities will be essential for making informed purchasing decisions that align with production goals.

| Machine Type | Best For | Max Flanging Thickness | Production Capacity | Power Consumption |

|---|---|---|---|---|

| Manual Flanging Machine | Small workshops | 3 mm | 50-100 units/day | 1 kW |

| Semi-Automatic Flanging Machine | Medium-scale production | 5 mm | 200-300 units/day | 2 kW |

| Fully Automatic Flanging Machine | Large factories | 10 mm | 500+ units/day | 5 kW |

| Hydraulic Flanging Machine | Heavy-duty applications | 15 mm | 100-200 units/day | 3 kW |

| Electric Flanging Machine | General metalworking | 8 mm | 150-250 units/day | 2.5 kW |

When choosing a head flanging machine, the significance of evaluating machine specifications and capabilities cannot be overstated. Specifications such as the machine’s material compatibility, flange size range, and processing speed directly affect the quality and efficiency of the flanging process. Understanding the intended application will help narrow down choices, ensuring that the selected machine meets the necessary standards for production. For instance, machines designed for high-speed operations often have advanced features that enhance precision and reduce cycle times, making them more suitable for large-scale manufacturing.

Moreover, the capabilities of a machine extend beyond its basic specifications. Features such as automation, user-friendliness, and ease of maintenance can greatly influence operational efficiency. Machines equipped with automated settings allow for consistent flanging results with minimal manual intervention, whereas user-friendly interfaces can reduce training time for operators. Additionally, considering the manufacturer’s support and availability of spare parts is crucial for minimizing downtime and ensuring longevity in rigorous production environments. Prioritizing these specifications and capabilities will lead to a more informed decision, ultimately optimizing manufacturing processes.

When investing in a head flanging machine, assessing your budget and cost-effectiveness is crucial for making a sound decision. First, it’s important to evaluate the initial purchase cost alongside the long-term operational costs. Factors such as maintenance, energy consumption, and the cost of replacement parts can significantly affect the total expenditure over the machine's lifespan. A comprehensive cost-effectiveness analysis allows buyers to identify machines that not only fit their immediate financial constraints but also promise efficiency and durability, minimizing unexpected expenses.

Additionally, companies should consider financing options and potential return on investment (ROI) when selecting a machine. Understanding the potential impact on productivity and quality can guide decision-makers in prioritizing features that align with their operational goals. In industries where advances in technology, such as artificial intelligence, are influencing costs and workflows, the right machine can enhance production capabilities and streamline processes, ultimately leading to better resource allocation and improved financial performance.

When investing in a head flanging machine, understanding the importance of customer support and warranty is crucial. A robust warranty plan can protect your investment and ensure peace of mind. Industry reports indicate that equipment downtime can cost manufacturers upwards of $250,000 daily. Thus, having a comprehensive warranty can mitigate these risks by covering vital parts and services, allowing businesses to maintain their production flow without unexpected expenses.

Additionally, excellent customer support is imperative, especially when dealing with specialized equipment like flanging machines. Manufacturers with high customer satisfaction ratings often provide quicker response times for service calls and better access to spare parts. Data from recent surveys show that companies with a strong focus on customer service can enhance loyalty and drive long-term growth, which is particularly important in the competitive manufacturing landscape. Investing in a machine with a reliable warranty and dedicated support can ultimately lead to improved operational efficiency and reduced costs over time.