Leave Your Message

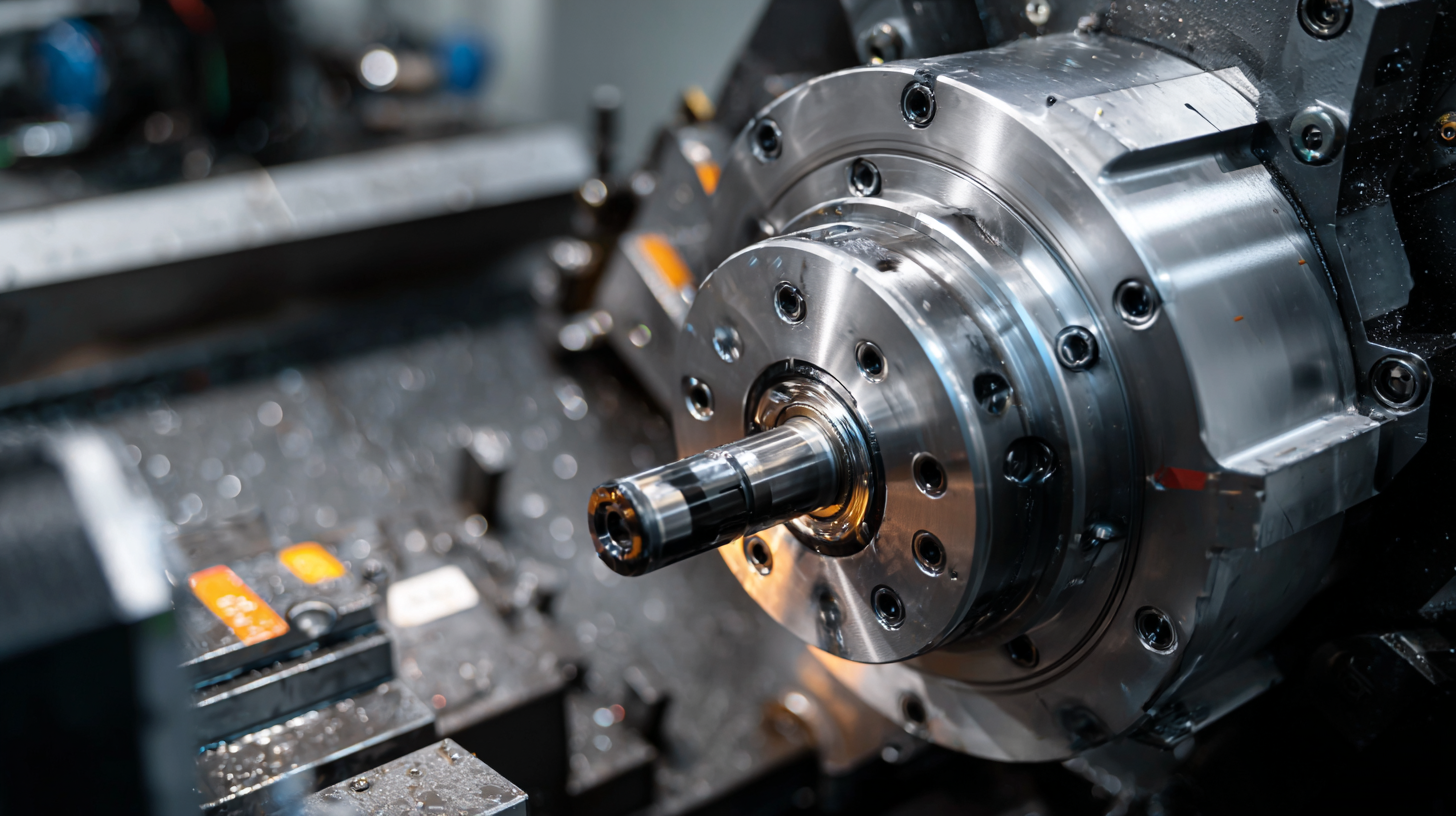

In the ever-evolving landscape of modern manufacturing, the versatility and efficiency of Metal Spinning Equipment have emerged as pivotal assets. This innovative machinery allows manufacturers to produce complex geometries with impressive speed and precision, making it an invaluable component in various industries, ranging from aerospace to automotive. As production demands increase and designs become more intricate, the applications of metal spinning have expanded, leading to creative solutions that enhance both functionality and aesthetics.

This article explores the "Top 5" innovative uses of Metal Spinning Equipment that are redefining manufacturing techniques today. By examining these applications, we will uncover how businesses leverage this technology not only to streamline their processes but also to drive sustainability and cost-effectiveness. From custom components to artistic designs, the adaptability of metal spinning is reshaping product development, showcasing its importance in meeting the challenges of contemporary manufacturing. Join us as we delve into these exciting advancements and their implications for the future of manufacturing.

Metal spinning is emerging as a transformative technology in the automotive sector, especially in the realm of lightweight design. With the increasing emphasis on fuel efficiency and performance, manufacturers are exploring innovative techniques to reduce vehicle weight without sacrificing strength. Metal spinning, a process that creates symmetrical parts from a metal disc, enables the production of complex, lightweight components that can significantly enhance the overall efficiency of vehicles. This approach not only minimizes material usage but also allows for intricate designs that optimize aerodynamics.

In conjunction with advancements in materials science, such as breakthroughs in magnesium alloys, the combination of metal spinning and lightweight design presents exciting opportunities for automotive engineers. The ability to produce robust components that are lighter contributes to better fuel efficiency and improved driving dynamics. Additionally, as automakers pivot towards sustainable practices, the innovations in metal spinning techniques align perfectly with the industry's goals, leading to the development of vehicles that meet both performance standards and environmental considerations. The future of automotive manufacturing is clearly being shaped by these pioneering approaches, streamlining production and enhancing the capabilities of modern vehicles.

This chart illustrates the various impacts of metal spinning techniques on modern manufacturing, particularly in the automotive sector. Each category represents a key aspect of the effectiveness of metal spinning, with scores reflecting its significance in enhancing lightweight design and production efficiency.

In the realm of modern aerospace manufacturing, metal spinning has emerged as a crucial technique for achieving precision in component fabrication. The recent advancements in this method allow manufacturers to create complex geometries with tight tolerances, essential for high-performance aerospace applications. According to a report by MarketsandMarkets, the global aerospace metal spinning market is projected to reach $2 billion by 2025, fueled by the increasing demand for lightweight and durable components. This technique allows for reduced material waste and improved structural integrity, making it an ideal choice for producing parts like fuselage sections and engine components.

Tip: When considering metal spinning for aerospace applications, ensure that you engage with suppliers who have experience in aerospace standards, such as AS9100 certification. This guarantees that the spinning process meets the stringent quality requirements of the industry.

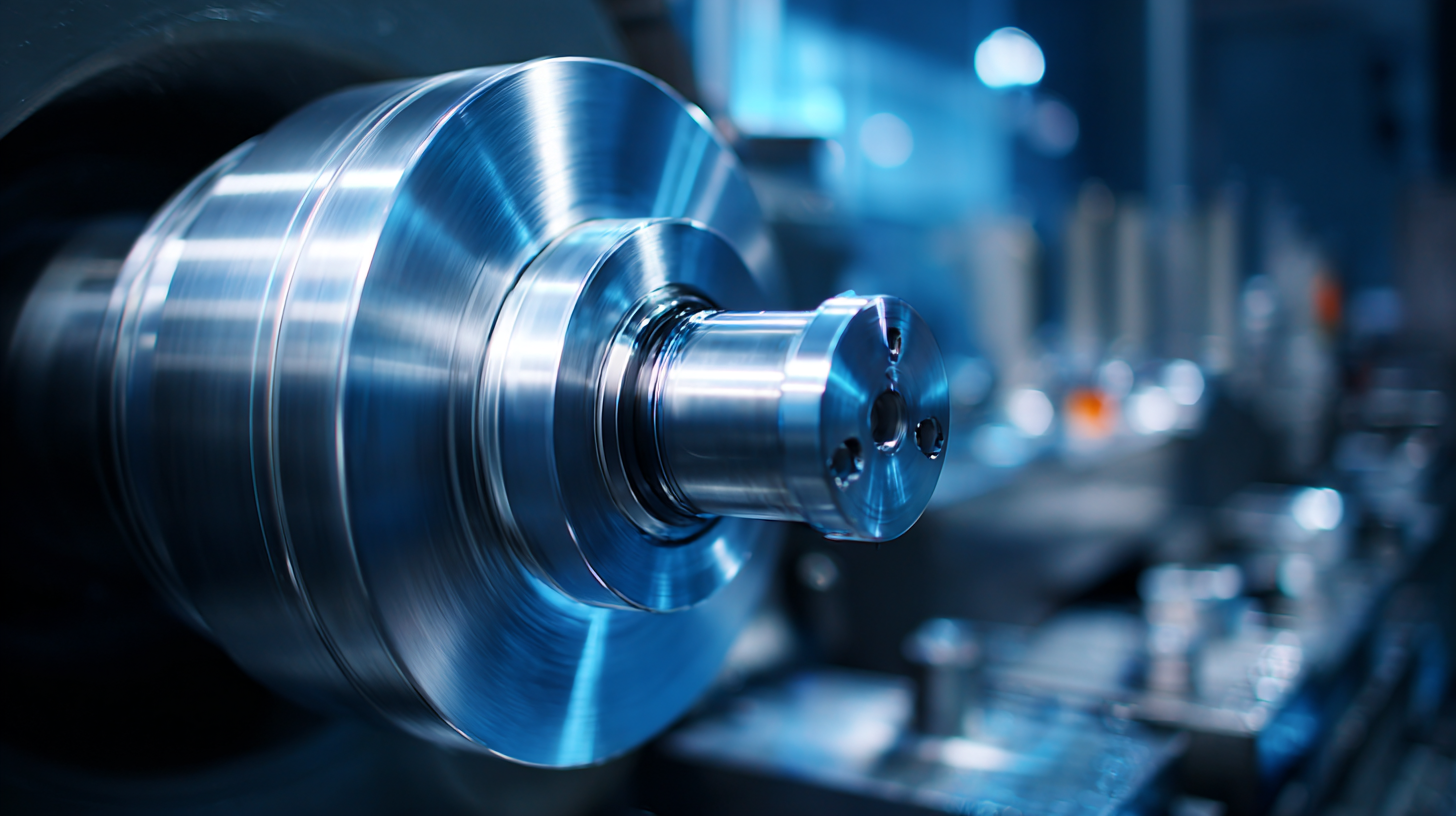

In addition to weight savings, metal spinning enables manufacturers to achieve superior surface finishes and enhanced mechanical properties. The process, which uses a rotating mandrel to shape metal, also allows for rapid prototyping, which is vital in the fast-paced aerospace sector. As reported by the International Journal of Advanced Manufacturing Technology, companies utilizing innovative manufacturing techniques, including metal spinning, have reported up to a 30% reduction in production time for complex parts.

Tip: Always conduct a cost-benefit analysis when integrating metal spinning into your manufacturing processes. Assess both upfront costs and potential savings over the product lifecycle to ensure a worthwhile investment.

Metal spinning has emerged as a transformative technique in the manufacturing sector, particularly in the production of turbine components. This process, which involves deforming a metal disc into a desired shape over a rotating mandrel, offers significant advantages in creating highly precise and lightweight parts. Turbines, which require optimal functionality and durability, benefit from the inherent strengths of metal spinning due to its ability to produce seamless and robust structures that can withstand extreme conditions.

In the context of energy solutions, metal spinning facilitates the production of components like turbine housings and blades. These parts can be crafted to exact specifications, reducing material wastage and enhancing performance efficiency. By using advanced spinning technologies, manufacturers are able to experiment with various alloys and composites, leading to innovations that enhance energy conversion processes. This adaptability not only supports the growing need for sustainable manufacturing practices but also fosters advancements in renewable energy technologies, such as wind and hydroelectric power, ultimately contributing to a greener future.

| Application Area | Material Used | Process Benefits | Industry Impact | Example Products |

|---|---|---|---|---|

| Turbine Housings | Aluminum Alloys | Lightweight and Durable | Enhances Energy Efficiency | Wind Turbines |

| Cylindrical Shells | Stainless Steel | Corrosion Resistance | Improves Longevity | Marine Turbines |

| Conical Shapes | Copper Alloys | Excellent Thermal Conductivity | Enhances Performance | Gas Turbines |

| Complex Geometries | Titanium Alloys | High Strength-to-Weight Ratio | Supports Advanced Applications | Aerospace Turbines |

| Custom Shapes | Carbon Steel | Cost-Effective Production | Significant Cost Savings | Industrial Turbines |

Metal spinning has emerged as a vital technique in modern manufacturing, particularly in industries like oil and gas, where supply chain resilience is critical. The ability to produce custom designs using metal spinning not only enhances product adaptability but also supports rapid response to unforeseen challenges imposed by geopolitical instability and environmental concerns. By utilizing this technology, companies can create tailored components that meet specific requirements, thereby improving efficiency and reducing lead times in their operations.

Metal spinning has emerged as a vital technique in modern manufacturing, particularly in industries like oil and gas, where supply chain resilience is critical. The ability to produce custom designs using metal spinning not only enhances product adaptability but also supports rapid response to unforeseen challenges imposed by geopolitical instability and environmental concerns. By utilizing this technology, companies can create tailored components that meet specific requirements, thereby improving efficiency and reducing lead times in their operations.

The flexibility inherent in metal spinning allows manufacturers to modify existing designs or create entirely new configurations with relative ease. This adaptability is particularly important in the rapidly changing landscape of the oil and gas sector, where the demand for innovative solutions is high. Custom metal spinning can enable the production of unique parts that are essential for maintaining operational integrity and efficiency, ultimately ensuring that supply chains can withstand external pressures while remaining competitive in a challenging market environment.

Sustainable manufacturing has become a paramount focus in the industry as companies strive to reduce waste and enhance efficiency. Metal spinning, a traditional manufacturing technique, has found renewed relevance in this context. By utilizing advanced metal spinning equipment, manufacturers can create components with minimal material waste. This process involves spinning a metal disk on a lathe while applying force to shape it into specific forms, allowing for highly precise designs that require less raw material compared to traditional methods like machining or casting.

Sustainable manufacturing has become a paramount focus in the industry as companies strive to reduce waste and enhance efficiency. Metal spinning, a traditional manufacturing technique, has found renewed relevance in this context. By utilizing advanced metal spinning equipment, manufacturers can create components with minimal material waste. This process involves spinning a metal disk on a lathe while applying force to shape it into specific forms, allowing for highly precise designs that require less raw material compared to traditional methods like machining or casting.

Moreover, the efficiency of metal spinning not only reduces waste but also diminishes energy consumption. The quick setup times and reduced cycle times involved in metal spinning translate to lower energy costs and a smaller carbon footprint. As manufacturers integrate these innovative metals spinning techniques, they not only improve their operational efficiency but also contribute to a more sustainable manufacturing landscape. Emphasizing the importance of recycling and reusing scrap material generated during the spinning process further enhances the sustainability of these operations, showcasing how traditional techniques can align with modern environmental goals.