Leave Your Message

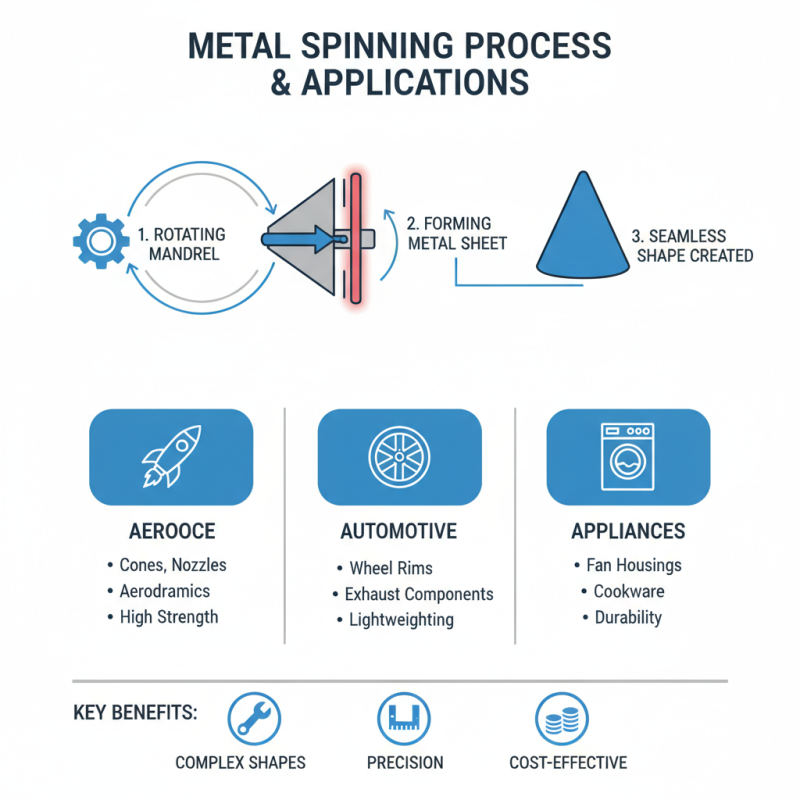

The Metal Spinning Cone plays a vital role in contemporary manufacturing. Its unique shape allows for versatile applications in various industries. Metal spinning is a process that creates precise and efficient components, making it essential.

This technology provides consistent quality and efficiency. Parts created with the Metal Spinning Cone can range from simple to complex designs. The ability to mold materials with varying thicknesses contributes to its functionality. Manufacturers appreciate its adaptability and cost-effectiveness.

However, challenges exist in achieving perfection. The process requires skilled operators for optimal results. Errors can arise from misalignment or incorrect settings. Reflection on these challenges can lead to innovations, enhancing the Metal Spinning Cone's contribution to modern manufacturing.

The metal spinning cone plays a crucial role in precision engineering. This process allows for the creation of intricately shaped parts from metal sheets. These components are often used in various industries, including aerospace and automotive.

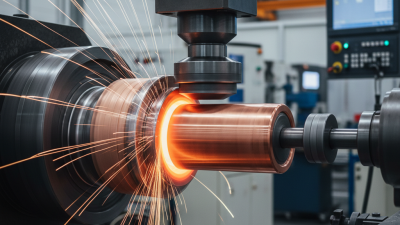

Metal spinning is not just about shaping metal; it requires skill and precision. Operators must ensure the metal is heated properly before spinning. The right temperature is vital. If it's too cold, the metal may crack. If too hot, it can lose shape. Each piece is unique, requiring meticulous attention.

Errors can occur during the spinning process. Sometimes, the thickness of the material varies, affecting the final product. Operators often need to adjust techniques based on the specific qualities of the metal used. It is a constant learning curve. Modern manufacturing demands not only efficiency but also adaptability.

| Feature | Description | Application | Material Used | Benefits |

|---|---|---|---|---|

| Precision | Achieves high accuracy in dimensions | Aerospace components | Aluminum, Titanium | Reduced material waste |

| Versatility | Compatible with various shapes and designs | Automotive parts | Stainless Steel, Brass | Customizable production |

| Efficiency | Fast production rates | Industrial machinery | Nickel Alloys | Lower labor costs |

| Strength | Creates durable and strong parts | Construction equipment | Carbon Steel | Enhanced product life |

| Cost-effectiveness | Minimizes waste and reduces costs | Consumer electronics | Copper | Lower manufacturing costs |

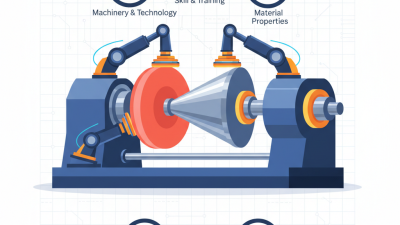

Metal spinning is a vital process in various manufacturing sectors. It allows for the creation of complex shapes and forms from metal sheets. This technique is widely used in industries such as aerospace, automotive, and appliances. In aerospace, for instance, metal spinning is crucial for producing conical shapes that help optimize aerodynamics. These components must meet high standards for strength and precision.

In the automotive industry, metal spinning is present in parts like wheel covers and exhaust tips. The process ensures uniform thickness and a clean finish. Manufacturers often cite efficiency as an advantage. However, some may overlook the need for quality checks. Imperfections can arise during spinning, leading to structural weaknesses. Regular monitoring can help mitigate these risks and improve overall product reliability.

Metal spinning is also significant in the appliance sector. Many household items rely on spun metal components, including lampshades and cookware. This method enables mass production with less waste. Yet, designers must constantly innovate to meet changing consumer expectations. Understanding the limitations of metal spinning is essential for maximizing its benefits. Emphasizing craftsmanship while embracing modern techniques can drive future advancements in this field.

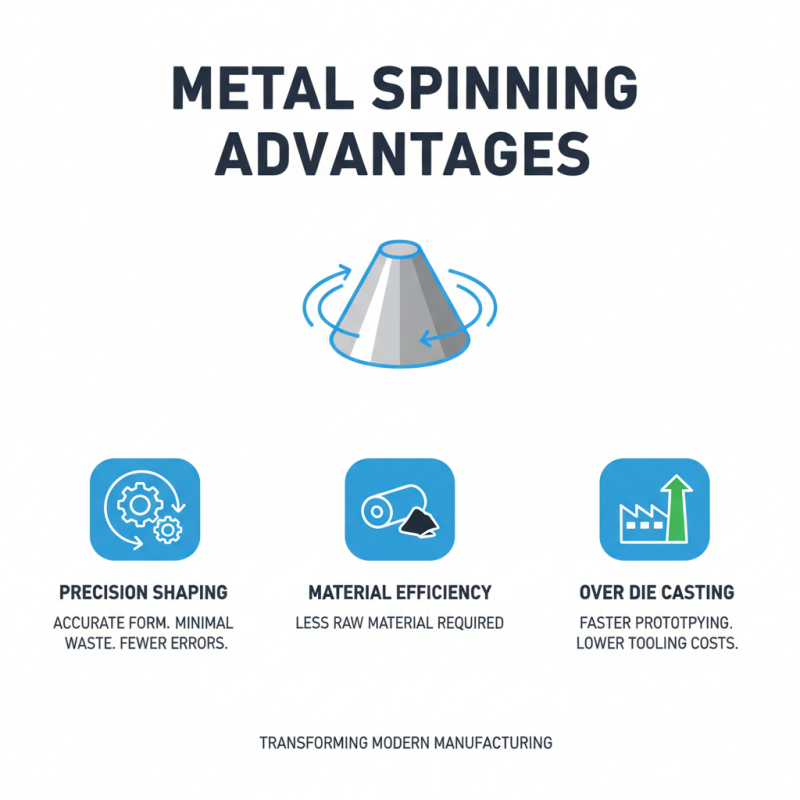

Metal spinning has transformed manufacturing. The metal spinning cone offers unique advantages over traditional methods. One major benefit is precision. It shapes metal accurately, minimizing waste. This means fewer errors during production. When compared to die casting, metal spinning requires less material.

Another advantage is flexibility. With spinning, manufacturers can create various shapes quickly. This is crucial for custom projects. Traditional methods may rely on molds, which can be costly and time-consuming. In contrast, a spinning cone can adapt to different designs without significant downtime.

However, it is important to consider the limitations. Not all materials are suitable for spinning. Some alloys may not perform well. Manufacturers must experiment to find the best fit. Additionally, skill is needed. Workers must be trained to use spinning equipment effectively. It’s a process that requires attention. This reflects a blend of technology and craftsmanship.

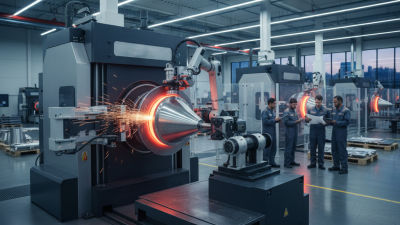

Metal spinning has undergone significant technological transformations over the past decade. According to a report by the International Journal of Advanced Manufacturing Technology, efficient processes can reduce material waste by up to 30%. Innovations in CNC technology allow for precise shaping of metals, enhancing accuracy while minimizing time. This shift not only boosts productivity but also reduces costs for manufacturers.

Automation in metal spinning is another key breakthrough. The integration of robotics has improved cycle times considerably. A recent study highlighted that automated systems could increase output by 25% in certain applications. However, companies still face challenges in adopting these advanced technologies. Many facilities are not fully equipped for integration, leading to inconsistencies in production quality.

Furthermore, there is a growing need for skilled labor to operate and maintain these systems. Training remains inadequate, causing a skills gap in the workforce. As manufacturers push for more advanced setups, the reliance on skilled operators becomes crucial. Balancing automation with human expertise poses ongoing challenges for the industry. It is clear that while these innovations promise efficiency, they also require ongoing reflection and adaptation.

Metal spinning is evolving rapidly. The technique focuses on forming metal into precise shapes using a spinning method. Recently, innovations in this area have emerged. Manufacturers are keen to adopt these advancements for better efficiency.

One key trend is automation. Automated spinning machines reduce human error and increase production speed. They can handle complex designs with ease. This saves time and lowers labor costs. However, some manufacturers face challenges in training staff to operate these new systems.

Another important trend is the use of advanced materials. Lightweight metals are becoming popular because of their strength-to-weight ratio. While this opens new design possibilities, it also requires engineers to rethink traditional spinning methods. There is still a lot to learn about the long-term effects of these materials on durability.

Manufacturers need to engage in continuous research to ensure reliability and sustainability in their processes.