Leave Your Message

In the fast-paced world of manufacturing, efficiency and precision are paramount. One pivotal piece of equipment that has emerged as a necessity in various production lines is the Fan Flanging Machine. This specialized machine streamlines the process of creating flared edges on fan components, ensuring that they fit seamlessly and securely into the overall assembly. By maximizing the effectiveness of this process, manufacturers can not only enhance the quality of their products but also significantly reduce production time and waste.

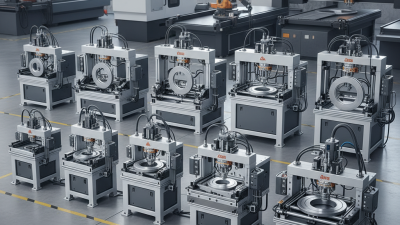

The integration of a Fan Flanging Machine into manufacturing processes offers numerous advantages. Its automation capabilities reduce the need for manual labor, allowing skilled workers to focus on more complex tasks while the machine handles repetitive flanging operations. Furthermore, this machine guarantees uniformity in each piece produced, which is crucial for maintaining high quality standards in today's competitive market. As industries continue to seek ways to optimize their operations, the Fan Flanging Machine has cemented itself as a vital tool for achieving superior manufacturing outcomes.

Fan flanging machines play a crucial role in the modern manufacturing landscape, particularly in industries where efficiency and precision are paramount. These machines streamline the process of creating flanges on fan components, ensuring a perfect fit while reducing the time and labor involved. The ability to produce consistent and high-quality flanges means manufacturers can meet the increasing demands for speed and accuracy in their operations, enhancing overall productivity.

Moreover, the significance of fan flanging machines extends beyond mere efficiency. They contribute to improved product quality and reliability, as precise flanging reduces the likelihood of malfunctions or defects in the final product. By incorporating these machines into manufacturing processes, companies can not only expedite their production timelines but also increase the durability and performance of their products. This alignment of speed and quality is vital in maintaining competitive advantage within the manufacturing sector.

| Feature | Description | Benefits | Industry Applications |

|---|---|---|---|

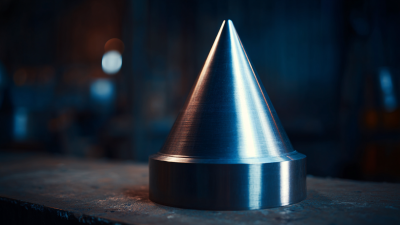

| Precision Engineering | Allows for accurate and consistent fan flange formations. | Improved product quality and reduced rework. | Aerospace, Automotive |

| Increased Productivity | Automated operations reduce manual labor. | Higher output rates and lower labor costs. | HVAC, Manufacturing |

| Versatility | Compatible with various materials and sizes. | Flexibility in production line design. | Electronics, HVAC |

| Enhanced Safety | Built-in safety features protect operators. | Minimized workplace accidents and injuries. | General Manufacturing, Aerospace |

| Cost Efficiency | Reduces material waste with precise flanging. | Lower production costs over time. | HVAC, Industrial Equipment |

Fan flanging machines play a crucial role in enhancing manufacturing efficiency, particularly in industries that require precision and speed. One of the key advantages of these machines is their ability to produce consistent and high-quality flanges with minimal human intervention. This not only leads to reduced labor costs but also minimizes the likelihood of errors, which can result in waste and rework. By automating the flanging process, manufacturers can significantly improve their output while maintaining product integrity.

Another significant benefit of using fan flanging machines is their versatility. These machines can handle various materials and sizes, making them ideal for a wide range of applications. This adaptability allows manufacturers to streamline their operations, as they can utilize a single machine for multiple projects. Additionally, modern fan flanging machines are equipped with advanced technology that enhances precision, ensuring that each flange meets the required specifications.

Tips: When considering the implementation of a fan flanging machine in your production line, evaluate the specific needs of your manufacturing process. It's essential to assess the types of materials you'll be working with and the volume of production required. Moreover, investing in training for your staff will maximize the machine's efficiency and improve overall workflow.

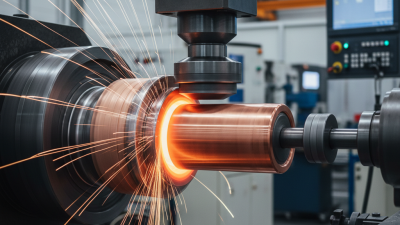

Fan flanging machines are essential tools in modern manufacturing processes, particularly in industries that require precision and efficiency in the fabrication of fan components. These machines enhance production efficiency by streamlining the flanging process, which involves creating a raised edge or lip at the perimeter of a fan blade or housing. By automating this task, fan flanging machines reduce the time and labor required for manual operations, leading to faster turnaround times and increased overall output.

Moreover, the precision offered by fan flanging machines ensures that each flange is consistently produced to the required specifications, minimizing defects and the need for rework. This level of accuracy not only improves the quality of the final product but also enhances the reliability of the manufacturing process. Additionally, these machines can be integrated into existing production lines, allowing manufacturers to upgrade their capabilities without significant disruptions. As a result, incorporating fan flanging machines into manufacturing operations can lead to substantial cost savings and a marked improvement in productivity.

When selecting the right fan flanging machine for your manufacturing needs, it's essential to consider several critical factors that will ensure optimal performance and efficiency. First, assess the volume of production required. Different machines are designed to handle varying capacities, so understanding your operational needs will help you choose a machine that can keep pace with your manufacturing goals. A machine that is too small may hinder production, while one that is excessively large may lead to unnecessary costs and complexities.

Another vital consideration is the type of materials you will be working with. Fan flanging machines can process different materials, and selecting one that aligns with your specific requirements is crucial. For instance, if your production involves high-strength alloys or specific composites, ensure that the machine you choose is compatible with these materials.

Additionally, evaluate the machine's features, such as speed settings, ease of use, and precision. A user-friendly machine can reduce operator errors and improve overall efficiency in the manufacturing process, while advanced features can enhance production quality and minimize waste.

Lastly, consider the support and maintenance services available for the machine. A reliable support system ensures that any issues can be quickly addressed, minimizing downtime and enhancing productivity. Investing in a fan flanging machine that comes with solid support will lead to better long-term performance and more effective manufacturing processes. By taking these factors into account, you can confidently choose a fan flanging machine that meets both your current and future manufacturing needs.

To ensure optimal performance of a fan flanging machine, regular maintenance is crucial. Operators should implement a routine inspection schedule that includes checking for signs of wear on critical components such as the flanging rollers and motor. Any abnormal noise or vibrations during operation could indicate that parts need lubrication or replacement. Keeping the machine clean and free of debris is essential to prevent malfunctions and ensure quality output, as accumulated dust and residue can affect the precision of the flanging process.

Additionally, operators should pay close attention to the machine’s calibration. Regularly calibrating the equipment not only enhances accuracy but also extends its lifespan. Documentation of maintenance activities and any adjustments made can help in identifying recurring issues and improving overall efficiency. Furthermore, maintaining a well-stocked inventory of replacement parts can minimize downtime in case of repairs. By following these maintenance tips, manufacturers can maximize the performance of their fan flanging machines, ultimately leading to more efficient production processes.