Leave Your Message

The Spinning Metal Disc is a fascinating device used in various applications today. Dr. Alice Harmon, a leading expert in rotational dynamics, once stated, "The laws of physics truly come alive when you understand how a spinning metal disc functions." This statement highlights the complexity and beauty of this seemingly simple object.

A Spinning Metal Disc operates on principles of angular momentum. As it spins, it creates stability and balance. This behavior has practical implications in fields like engineering and material science. For example, its use in flywheels enhances energy storage systems. However, there are challenges too. Not all designs achieve the intended efficiency.

Exploring the mechanics of a Spinning Metal Disc allows us to appreciate its role in technology. Yet, the pursuit of perfection in design raises questions. Are we overlooking potential improvements in materials? How can we innovate further? These reflections drive the industry forward.

A spinning metal disc is a fascinating object often used in various applications. It is characterized by its round shape and the ability to rotate around a central axis. Typically made from materials like steel or aluminum, these discs can achieve high rotational speeds. The design allows them to maintain balance and stability while in motion.

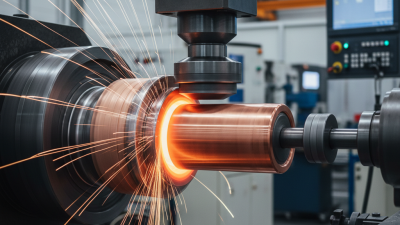

The mechanics behind a spinning metal disc are intriguing. When it spins, centrifugal force comes into play, creating a dynamic movement. This force pushes the material outward, affecting its behavior and performance. A well-crafted disc can demonstrate impressive resilience, yet imperfections can lead to wobbling. Such inconsistencies might not always be visible, but they can impact efficiency.

In many ways, spinning metal discs are simple yet complex. They represent a delicate balance of engineering and physics. Observing their motion invites reflection on the principles of rotation and force. Each spin tells a story of creation and potential. However, even a minor flaw can disrupt this harmony. Understanding these nuances is key to appreciating their role in technology and design.

A spinning metal disc is a fascinating object that embodies principles of physics. When the disc rotates, it experiences forces that govern its motion. Centripetal force is one such force, acting toward the center of the circle around which the disc spins. This force is crucial for keeping the disc in a circular path, preventing it from flying off into the air. Without this inward pull, the disc would simply drift away, losing its shape and functionality.

Angular momentum also plays a key role in understanding how a spinning disc works. It describes how much motion the disc has while spinning and depends on both the speed of rotation and the mass distribution. A heavier disc, rotating faster, will exhibit greater angular momentum. This means it will be harder to stop or change the direction of the spin. Many might think that stopping a fast-spinning disc is easy, but it requires significant effort. In this process, energy is dissipated, leading to heat and friction, making one wonder about the balance between motion and stillness.

| Property | Value |

|---|---|

| Material | Aluminum |

| Diameter | 0.5 m |

| Thickness | 0.02 m |

| Rotational Speed | 3000 RPM |

| Centripetal Force | Calculated based on mass and speed |

| Angular Momentum | Dynamic based on rotational speed |

| Frictional Forces | Depends on surface material |

| Applications | Flywheels, gyroscopes, and mechanical devices |

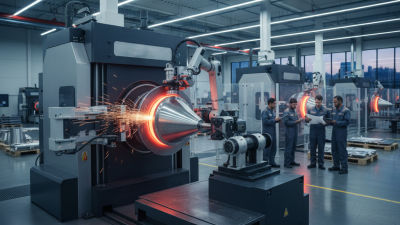

Spinning metal discs find diverse applications in various industries. These discs are used in centrifuges, which separate substances based on density. In laboratories, centrifuges operate at high speeds, often exceeding 10,000 RPM. This allows for effective separation of blood components or chemical mixtures. In the aerospace industry, spinning discs support testing materials and structural components. They simulate extreme conditions that parts may experience during flight.

Data from a recent industry report indicates that the centrifuge market is projected to reach $4 billion by 2025. This growth stems from increased demand in biotechnology and pharmaceutical sectors. Many companies struggle with the challenges of optimizing spin speeds. Balancing speed with stability often leads to equipment failures. Discs must maintain structural integrity while performing under pressure.

Spinning discs also play a role in renewable energy setups, particularly in wind turbines. They help manage load and energy distribution. Emerging technologies aim to improve efficiency, but obstacles remain. Engineers must consider factors like material wear and fatigue. Such considerations demand innovation and continuous improvement in design and application.

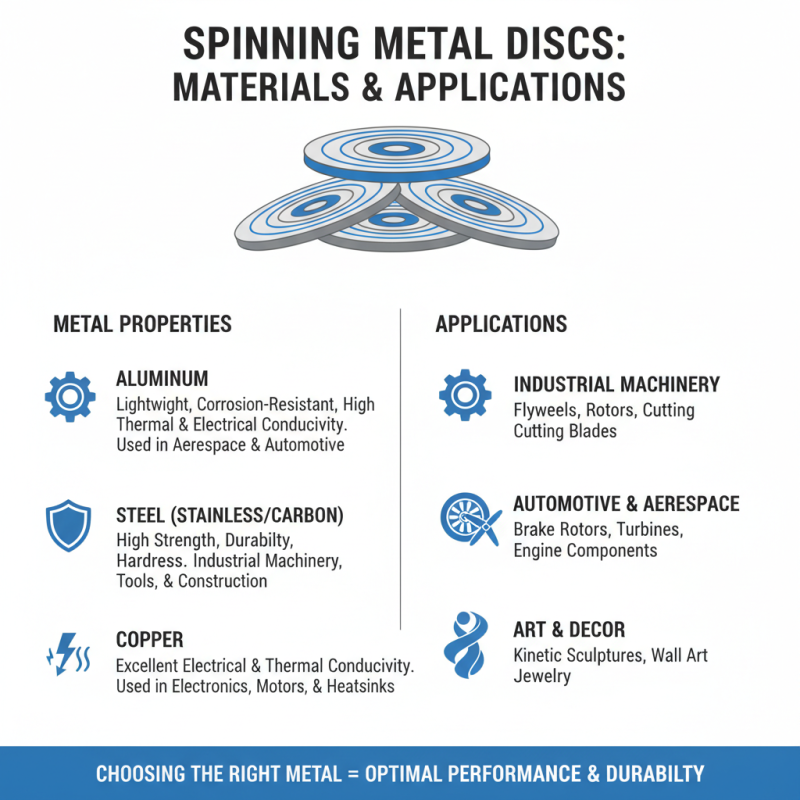

Spinning metal discs have various applications, from industrial machinery to art. The choice of metal significantly influences their performance. Different metals exhibit unique properties. Understanding these properties helps in selecting the right material.

Aluminum is popular for its lightweight nature. It offers good strength and resistance to corrosion. However, it can be less durable than some other metals. This can pose a challenge in demanding environments.

Steel is another common choice. It provides excellent strength and durability. Available in various grades, steel can withstand high pressures. Yet, it can be heavier and more prone to rust without proper treatment. Investigating other metals, like brass, may yield interesting results. Brass is easy to work with but can be softer, leading to rapid wear under stress.

Operating a spinning metal disc requires strict adherence to safety and maintenance protocols. This ensures not only the longevity of the equipment but also the safety of operators. According to industry reports, around 20% of workplace accidents involve machinery like metal discs. Regular maintenance checks can significantly reduce this risk. Inspect the disc for any signs of wear or damage before each use. Ensure that all safety guards are in place and functioning.

Proper training is essential. Operators should be familiar with emergency stop mechanisms and safe operational procedures. Data shows that facilities with comprehensive training programs see 30% fewer accidents. Wearing appropriate personal protective equipment (PPE) is non-negotiable. This includes eye protection and, if necessary, face shields.

Another crucial aspect is keeping the workspace organized. Clutter can lead to distractions and accidents. Metal shavings and debris must be cleaned regularly to avoid slips. Reports indicate that an organized environment leads to a 15% increase in productivity. Without attention to detail in safety and upkeep, even the best equipment can become a hazard. Regular training and maintenance checks are key, but they should be approached with a mindset for continuous improvement.