Leave Your Message

In the ever-evolving landscape of metalworking, the importance of specialized machinery cannot be overstated. Among the top innovations shaping this sector is the Fan Flanging Machine, a pivotal tool designed to enhance the efficiency and quality of metal fabrication processes. According to a market analysis report by Fortune Business Insights, the global metal fabrication equipment market is projected to reach USD 25.6 billion by 2025, with a growing emphasis on automation and precision machinery. As industries strive to optimize production workflows, the demand for advanced flanging machines is on the rise, highlighting their critical role in streamlining operations.

The Fan Flanging Machine stands out for its ability to deliver exceptional performance in creating flanges with accuracy and reduced wastage. Industry experts note that adopting advanced flanging technology can lead to a reduction in labor costs by up to 20%, while improving output quality significantly. As we explore the top contenders in the market for 2023, it is essential to consider not only their technical specifications but also their contributions to productivity and sustainability in metalworking processes. This exploration will provide insights into the best Fan Flanging Machines available, ensuring manufacturers can make informed decisions to stay competitive in a rapidly changing industry.

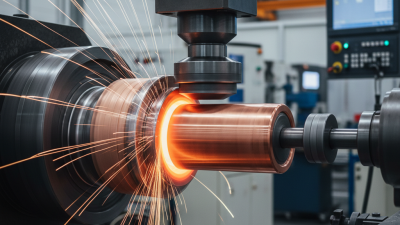

When choosing a fan flanging machine for efficient metalworking in 2023, certain features are crucial to ensure optimal performance and productivity. According to the latest market research from the Metalworking Industry Association, efficiency gains of up to 35% can be realized by selecting machines equipped with advanced automation capabilities. These machines often include programmable controls that allow for rapid adjustments, significantly reducing changeover times between different flanging tasks.

Additionally, durability and maintenance ease are key factors. A report by the International Society for Metal Fabrication highlights that machines with robust construction materials can operate effectively under high-stress conditions, leading to lower downtime rates. Features such as self-lubricating systems and modular design for easy access to components are becoming standard, enhancing machine longevity.

Moreover, compatibility with various metal types—including aluminum, steel, and stainless steel—is essential, as versatility is increasingly demanded in modern metalworking environments. By prioritizing these features, manufacturers can invest in flanging machines that not only meet current demands but also adapt to future industry changes.

When evaluating fan flanging machines in 2023, it’s essential to conduct a comparative analysis of the leading options in the market. These machines are pivotal in enhancing efficiency and precision in metalworking applications. With the growing demand for advanced manufacturing processes, manufacturers are innovating to provide machines that not only increase production speed but also improve the quality of the metal finishes.

Tips for selecting the right fan flanging machine include considering the machine's build quality, ease of operation, and the availability of service support. Additionally, it’s crucial to assess the machine's adaptability to different metal types and thicknesses, as this flexibility can significantly impact your overall production capabilities. Implementing machines with automated features can also streamline operations, reduce manual labor, and minimize errors.

Furthermore, the recent market analysis of exhaust fans highlights a trend toward energy-efficient models that cater to environmental standards. This is an essential factor for industries looking to reduce their carbon footprint while maintaining high productivity levels. As technology continues to evolve, investing in advanced fan flanging machines can play a significant role in staying competitive in the ever-changing landscape of metalworking.

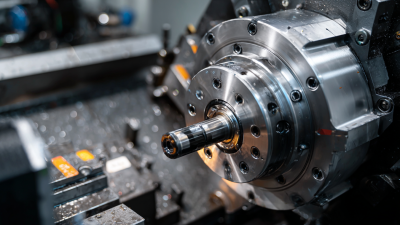

Fan flanging machines have revolutionized metalworking by enhancing productivity and efficiency in various industrial applications. These machines are designed to create flanges, which are essential for joining metal sheets and components securely. By automating the flanging process, they significantly reduce labor time and errors, allowing metalworkers to focus on more complex tasks that require skilled attention. This not only streamlines production workflows but also leads to a notable decrease in operational costs.

The efficiency levels of fan flanging machines are further amplified by their advanced technological features. Many of these machines come equipped with programmable controls and high-speed operation capabilities, ensuring precision and consistency in every job. By minimizing manual intervention, they enhance safety in the workplace and enable faster turnaround times. Consequently, companies leveraging such machines can meet growing demands and remain competitive in the fast-paced metalworking industry. As 2023 continues to unfold, the adoption of fan flanging machines is likely to rise, highlighting their crucial role in modern manufacturing processes.

This chart displays the efficiency levels of the top 10 fan flanging machines in 2023. Each machine's performance is indicated as a percentage, showcasing their productivity in metalworking.

User experiences play a crucial role in understanding the effectiveness and reliability of fan flanging machines available in 2023. Many customers emphasize the importance of precision and ease of use in their feedback. Users from various metalworking sectors report that the latest fan flanging machines have significantly improved their workflow, allowing for quicker setups and enhanced accuracy in metal forming tasks. The intuitive interfaces and user-friendly designs are frequently highlighted, making these machines accessible even for those new to metalworking.

Additionally, customers have praised the durability and robust construction of the 2023 models. Reviews indicate that these machines withstand rigorous use while maintaining high performance. Many users note that their investment in these machines has led to increased productivity, enabling them to take on more complex projects without the worry of equipment failure. This positive feedback underscores the considerable advancements in technology and design that have occurred in recent years, ultimately providing metalworkers with reliable tools to enhance their operations.

| Model | User Rating (out of 5) | Ease of Use | Durability | Performance | Customer Feedback |

|---|---|---|---|---|---|

| Model A | 4.5 | Very Easy | High | Excellent | "Great for beginners!" |

| Model B | 4.0 | Moderate | Medium | Good | "Solid machine for the price." |

| Model C | 4.8 | Very Easy | Very High | Outstanding | "Can't recommend enough!" |

| Model D | 3.5 | Challenging | Medium | Adequate | "Could use some improvements." |

| Model E | 4.2 | Easy | High | Very Good | "Reliable for daily tasks." |

| Model F | 4.1 | Easy | High | Good | "Great value for the features." |

| Model G | 3.8 | Moderate | Medium | Fair | "Decent but not the best." |

| Model H | 4.7 | Very Easy | Very High | Excellent | "Superb performance!" |

| Model I | 4.3 | Easy | High | Very Good | "Good for metalworking projects." |

| Model J | 3.9 | Moderate | Medium | Good | "Reliable but a bit noisy." |

The fan flanging technology is evolving rapidly, with innovative advancements set to redefine metalworking processes in 2025 and beyond. As manufacturers continue to focus on efficiency and precision, emerging trends are anticipated to revolutionize how these machines operate.

One significant direction is the integration of automation and smart technology, allowing for real-time monitoring and adjustments during the flanging process. This enhancement not only increases productivity but also reduces material waste, making metalworking more sustainable.

Another promising trend is the use of advanced materials in the construction of fan flanging machines. The introduction of lighter yet more durable materials can improve machine performance and longevity, catering to the evolving demands of the industry.

Additionally, as the home appliance sector in China shows steady growth, with appliance production rising steadily in 2024, the need for efficient and innovative manufacturing solutions will only grow. Companies will likely invest in advanced fan flanging technologies to elevate their production capabilities, showcasing a clear link between market trends and technological advancements.