Leave Your Message

The Spinning Forming Process has emerged as a pivotal technique in modern manufacturing, offering a wide range of advantages that enhance production efficiency and product quality. This innovative method involves the deformation of material into a desired shape through high-speed rotation, which not only allows for precise control over the final dimensions but also promotes optimal material usage. As industries continue to seek methods that improve sustainability and reduce waste, the Spinning Forming Process stands out for its ability to create complex geometries with minimal resource consumption.

In exploring the top benefits of the Spinning Forming Process, it becomes evident that this approach facilitates superior strength and durability in manufactured products. The continuous fiber alignment achieved during spinning significantly enhances the mechanical properties of the material, resulting in components that are lightweight yet robust. Additionally, the versatility of this process enables manufacturers to work with a variety of materials, further expanding its application across numerous sectors, from aerospace to automotive. This introduction sets the stage for a comprehensive examination of why the Spinning Forming Process is gaining traction as a preferred manufacturing technique in today's competitive landscape.

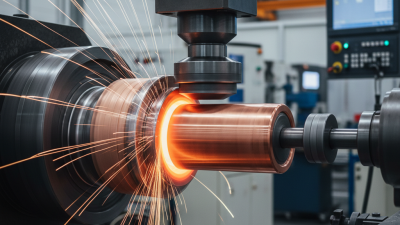

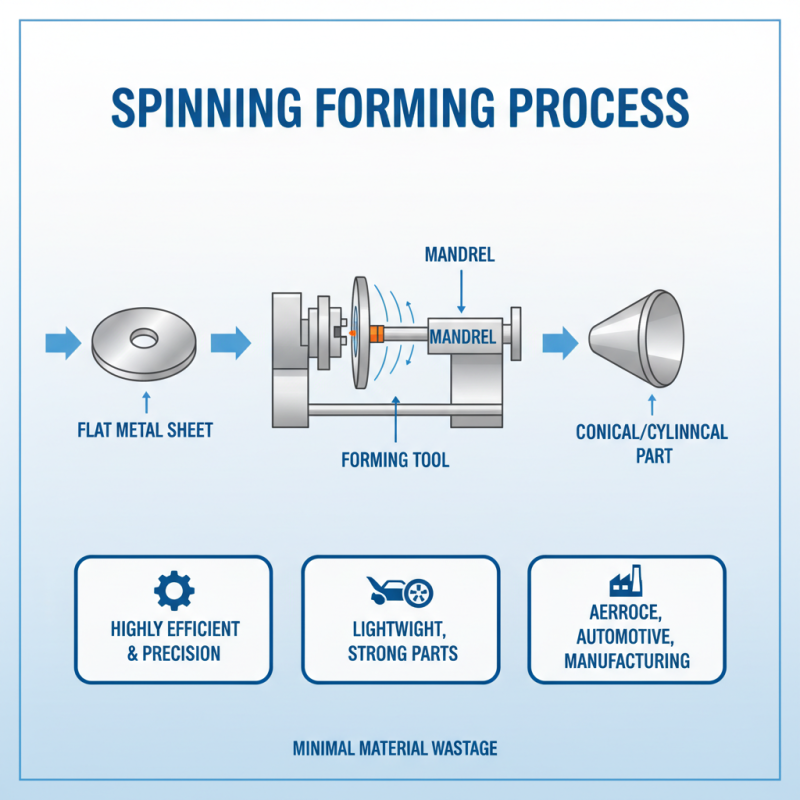

The spinning forming process is a highly efficient manufacturing technique that transforms flat metal sheets into intricate shapes through the application of rotational forces. By utilizing a spinning lathe, manufacturers can create a wide variety of cylindrical and conical components with precision and minimal material wastage. During the process, a blank metal disc is clamped and spun against a forming tool, which molds the material as it rotates. This technique is particularly favored for its ability to produce lightweight yet strong parts, making it valuable in industries such as aerospace, automotive, and general manufacturing.

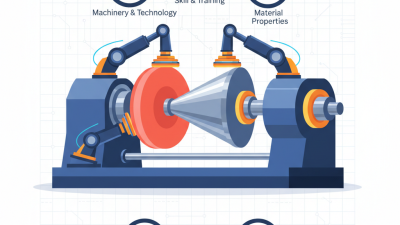

When considering the spinning forming process, it’s essential to focus on specific tips to enhance efficiency and quality. Firstly, ensure that the blanks used are of high-quality material suited for spinning; this minimizes defects and enhances the finished product's durability. Additionally, maintaining proper tool alignment and calibration can significantly reduce the risk of errors during the spinning process. Lastly, conducting regular training sessions for operators can improve skill levels, ensuring that all aspects of the process are executed flawlessly.

Emphasizing care during the setup and execution stages can lead to remarkable outcomes. For instance, paying attention to the speed and pressure of the spinning lathe can greatly impact the final product’s finish and structural integrity. Consistent monitoring and adjustments during the manufacturing process will help achieve the desired results while also maintaining a safe working environment.

The spinning forming process in manufacturing is renowned for its ability to enhance material efficiency significantly. By utilizing a method that involves rotating a blank under high-speed conditions, manufacturers can create parts from a diverse range of materials while minimizing waste. This technique allows for the effective distribution of material, ensuring that less raw material is required to produce components with intricate designs and desired strength characteristics. As a result, spinning not only conserves resources but also reduces costs associated with material procurement.

In addition to the reduction of waste, spinning techniques enable manufacturers to achieve greater uniformity and consistency in their products. The automated nature of the spinning process facilitates precise control over the thickness and shape of the material, which is crucial for maintaining quality standards. This enhanced material efficiency translates into better performance and durability of the final products, further optimizing the manufacturing workflow. Overall, the spinning forming process stands out as an innovative solution to elevate material efficiency, benefiting both the manufacturers and the environment.

The spinning forming process has gained traction in the manufacturing sector for its ability to enhance the mechanical properties of products. This method, which involves the deformation of metal through rotational motion, results in components that possess increased strength and durability. According to a report by the International Journal of Advanced Manufacturing Technology, products created through spinning can exhibit improved tensile strengths of up to 30% compared to those manufactured using traditional methods. The enhanced mechanical properties stem from the refined grain structure and work-hardening effects that occur during the spinning process.

Moreover, the spinning technique allows for the creation of complex shapes and lightweight components without sacrificing strength. This is particularly advantageous in industries such as aerospace and automotive, where weight reduction is crucial for performance and fuel efficiency. A study published in the Journal of Materials Processing Technology indicates that components produced by spinning possess superior fatigue resistance, often leading to longer service life and reduced maintenance costs. With an increasing focus on sustainability and efficiency in manufacturing processes, the spinning forming technique stands out by delivering products that not only meet stringent mechanical requirements but also contribute to overall cost-effectiveness in production.

| Benefit | Description | Impact on Mechanical Properties |

|---|---|---|

| 1. Enhanced Strength | The spinning process aligns the material's fiber direction, leading to improved tensile strength. | Higher resistance to deformation under load. |

| 2. Superior Ductility | Allows materials to undergo significant plastic deformation without fracturing. | Increased ability to absorb energy before failure. |

| 3. Reduced Weight | Thin-walled shapes minimize material use while maintaining strength. | Lightweight products enhance efficiency and reduce costs. |

| 4. Improved Fatigue Resistance | Uniform grain structure results in better fatigue performance. | Longer lifespan under cyclic loading conditions. |

| 5. Enhanced Surface Finish | Creates smoother surfaces reducing the need for secondary machining. | Improved corrosion resistance and aesthetic appeal. |

| 6. Cost Efficiency | Lower material waste and reduced processing time. | Overall savings in production costs. |

| 7. Flexibility in Design | Ability to create complex shapes and configurations easily. | Broader design possibilities without compromising properties. |

| 8. High Production Rates | Rapid cycle times allow for increased output. | Improved productivity and efficiency in the manufacturing process. |

| 9. Better Thermal Properties | Material enhancement leads to better heat dissipation. | Improved performance in high-temperature applications. |

| 10. Environmentally Friendly | Reduces waste and promotes the efficient use of materials. | Lower environmental impact compared to traditional methods. |

The spinning forming process has emerged as a significant technique in the manufacturing sector, especially for producing hollow and symmetrical parts. One of its key advantages lies in its cost-effectiveness, which can be attributed to material savings and reduced operational expenses. According to a recent industry report, spinning can reduce material waste by up to 30% compared to traditional machining methods, making it an economically viable option for manufacturers. Additionally, the lower energy consumption associated with spinning operations contributes to overall cost reductions. For instance, studies show that the energy requirements for spinning are approximately 20-40% less than those for processes like forging, which further enhances its attractiveness for companies looking to optimize production costs.

Time savings represent another major benefit of the spinning process. The efficient nature of spinning allows for rapid production cycles; some reports indicate that spinning can complete parts in significantly less time than alternative forming methods. For example, while conventional machining might take hours to create a part, spinning can often achieve similar results in a fraction of that time. This reduction in lead time not only accelerates the production timeline but also improves responsiveness to market demands. The combination of these time and cost efficiencies makes spinning a compelling choice for manufacturers seeking to enhance productivity while maintaining quality standards.

The spinning forming process is revolutionizing various sectors in manufacturing, with applications spanning aerospace, automotive, and metalworking industries. This technique is particularly advantageous for creating complex geometries in parts such as aircraft components, fuel tanks, and piping systems. According to market research, the global spinning industry is projected to grow by over 5% annually, highlighting its increasing relevance in production efficiency and material utilization.

In aerospace, the precision and strength of spun parts enhance safety and performance. Recent reports indicate that lightweight spun components can reduce overall aircraft weight by up to 15%, significantly improving fuel efficiency. Similarly, the automotive industry benefits from spinning techniques for producing lightweight yet durable parts that meet rigorous safety standards. These advantages are paving the way for innovative designs that were previously unfeasible with traditional forming methods.

Tip: When considering spinning forming for your manufacturing needs, it's important to evaluate the type of material being used. Metals like aluminum and titanium offer optimal results due to their workability and strength-to-weight ratios.

Another key area utilizing spinning is the energy sector, particularly in the fabrication of turbine casings and components. The precision achieved in this process leads to enhanced performance and longevity, which is essential in high-stakes environments. The demand for customized, high-tolerance parts continues to grow, making spinning an invaluable addition to modern manufacturing strategies.

Tip: Ensure that your design allows for the unique properties of spun materials. Collaborating closely with engineers familiar with spinning techniques can help maximize efficiency and minimize waste.