Leave Your Message

In the realm of advanced manufacturing, the Spinning Metal Process has emerged as a pivotal technique, offering unparalleled precision and efficiency. According to renowned industry expert Dr. James Whitaker, "The Spinning Metal Process is not just about shaping metal; it’s about pushing the boundaries of what is possible in manufacturing." This statement underscores the significance of this technique in revolutionizing how metal components are produced across various sectors. By manipulating metal in a controlled manner, manufacturers can create intricate shapes that are both lightweight and robust, meeting the ever-increasing demands for innovative design and functionality.

As we explore the top ten spinning metal process techniques for effective manufacturing, it becomes evident that the ability to adapt and refine these methods is crucial in today’s competitive landscape. The blending of traditional skills with cutting-edge technology allows practitioners to maximize efficiency while minimizing waste, thereby improving overall sustainability in production. Understanding these techniques not only enhances the operational capabilities of manufacturing companies but also ensures that they remain at the forefront of industry advancements. The adoption of such practices reflects a commitment to quality and innovation that is essential for success in the modern manufacturing environment.

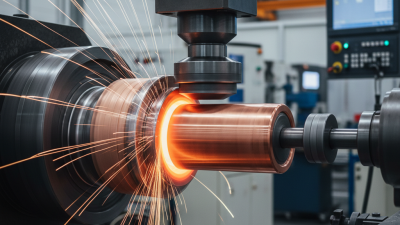

The spinning metal process is a crucial manufacturing technique that transforms flat metal sheets into complex shapes with high precision and efficiency. This method is widely used in various industries, from aerospace to automotive, highlighting its versatility. According to a report by MarketsandMarkets, the metal spinning market is expected to reach $1.5 billion by 2025, driven by increased demand for lightweight and durable components. A key advantage of spinning processes is their ability to minimize material waste while achieving design flexibility, making them a preferable choice for engineers.

When implementing spinning metal techniques, it's essential to optimize machine settings for different metals to ensure quality and consistency. For instance, softer metals like aluminum require different speeds and feed rates compared to harder ones such as titanium. Additionally, proper tooling and die design are critical for achieving the desired finish and precision.

Tip: Regularly maintain your machinery to prevent wear and tear, which can lead to production inconsistencies. Also, consider the use of lubrication to reduce friction during the spinning process, which not only improves surface finish but also extends tool life.

Another vital aspect is operator training. Skilled professionals can significantly enhance production efficiency, ensuring that each component meets specifications without compromising quality. Investing in training programs can bolster productivity and reduce error rates, ultimately leading to more competitive manufacturing outcomes.

Tip: Incorporate technology like CAD/CAM software to streamline design and improve communication between teams, facilitating a smoother transition from concept to production.

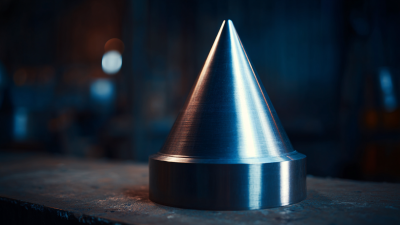

Metal spinning is a highly efficient manufacturing technique that requires a deep understanding of its core principles to achieve optimal results. One of the key principles of effective metal spinning is the selection of appropriate materials. Different metals exhibit varying malleability and strength properties, which directly influence the spinning process. Selecting a metal that can withstand the forces applied during spinning while maintaining its integrity is crucial. This careful material choice not only impacts the quality of the finished product but also influences the overall production efficiency.

Another important principle in effective metal spinning is the control of operational parameters such as speed, feed rate, and tooling accuracy. These parameters must be precisely adjusted to accommodate specific material characteristics and design requirements. For instance, higher spinning speeds can lead to increased centrifugal forces, but they also require meticulous control to avoid material fatigue or deformation. Furthermore, the use of high-quality tooling is essential to ensure the consistency and precision of the shapes being created. Ultimately, a strong grasp of these principles enables manufacturers to produce high-quality, durable metal components while optimizing their production processes.

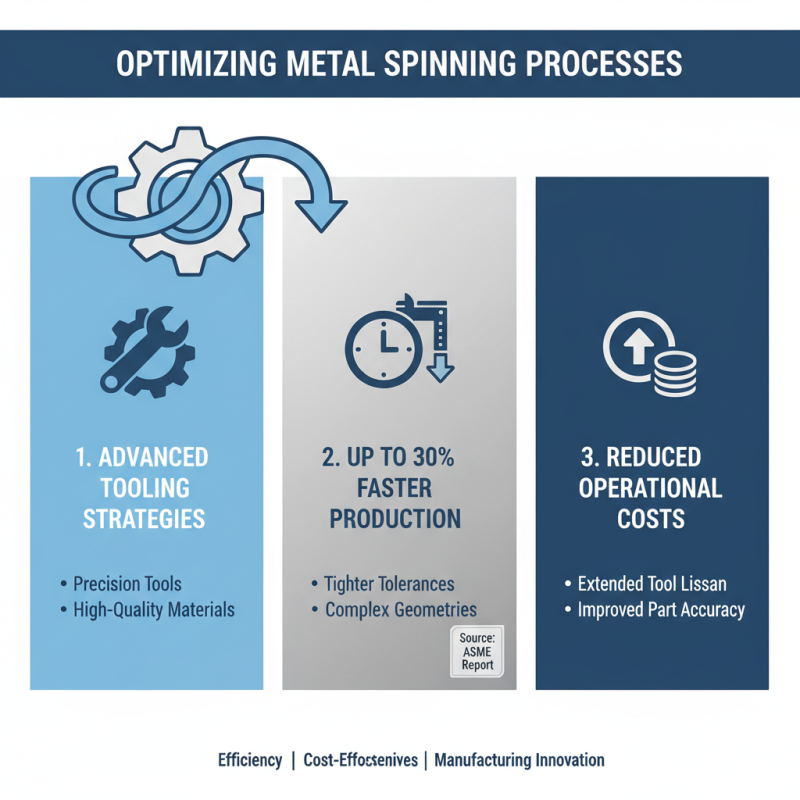

Optimizing metal spinning processes is crucial in achieving efficiency and cost-effectiveness in manufacturing. One of the primary techniques involves the application of advanced tooling strategies. According to a report from the American Society of Mechanical Engineers, enhanced tooling can reduce production time by up to 30%, allowing manufacturers to achieve tighter tolerances and more complex geometries. By investing in high-quality, precision tooling, manufacturers not only improve the accuracy of the spun parts but also significantly extend the lifespan of the tooling itself, reducing overall operational costs.

Another vital technique is the integration of automation in metal spinning operations. A study by the National Institute of Standards and Technology highlights that automation can increase production rates by 40% while maintaining consistent quality. By employing robotic systems for repetitive tasks, manufacturers can lessen the risk of human error and optimize workflow, allowing skilled operators to focus on more complex tasks that cannot be automated. Implementing automation solutions creates a leaner production environment and facilitates real-time data tracking, contributing to continuous improvement within manufacturing processes.

Furthermore, using advanced simulation software can greatly enhance process planning and optimization. By digitally modeling the spinning process, manufacturers can conduct thorough analyses to predict outcomes, identify potential issues, and fine-tune parameters before actual production begins. A report from the International Journal of Advanced Manufacturing Technology shows that manufacturers utilizing simulation saw a reduction in defects and rework by up to 25%, leading to a more streamlined production cycle and significant savings on resources and time.

In the realm of metal processing, spinning techniques have evolved significantly, transitioning from traditional methods to advanced technologies that enhance manufacturing efficiency. Traditional spinning methods often rely on manual operation, resulting in a slower production pace and variability in product quality. However, these methods can still be advantageous for small-scale projects or custom pieces, allowing greater control over the final design. The challenge lies in consistently achieving the same quality across larger production runs.

In contrast, advanced spinning methods utilize automation and computer numerical control (CNC) systems, which streamline production and improve precision. This shift not only minimizes human error but also allows manufacturers to create complex shapes and designs that were previously difficult to achieve. Additionally, advanced spinning techniques tend to offer better material utilization, reducing waste and overall costs.

Tip: To optimize your spinning process, consider integrating automation gradually. Start with a few automated tools in your existing setup to enhance efficiency without overhauling your entire system at once. Another tip is to invest in training for your operators on the latest technologies; this ensures that your workforce can effectively use advanced techniques, ultimately improving product quality and consistency.

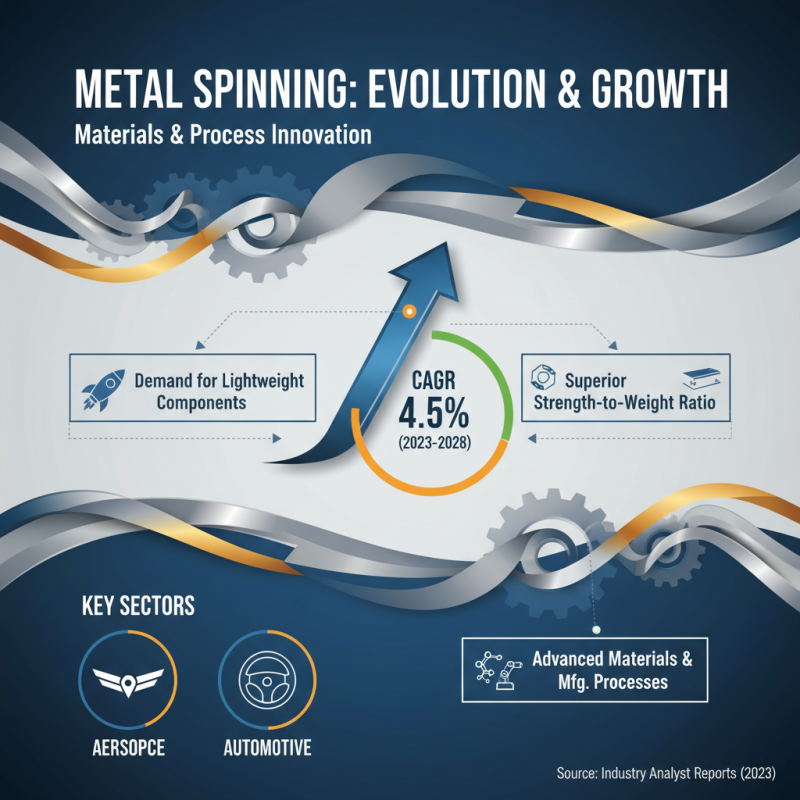

The landscape of metal spinning technology is on the brink of significant evolution, driven by advancements in materials and innovative manufacturing processes. Recent reports by industry analysts highlight that the metal spinning market is expected to witness a CAGR of 4.5% over the next five years. This growth is primarily attributed to the rising demand for lightweight components in sectors such as aerospace and automotive, where metal spinning offers superior strength-to-weight ratios compared to traditional machining methods.

Emerging technologies such as computer-aided design (CAD) and automation are set to transform metal spinning processes. CAD software allows for more precise designs and simulations, reducing waste and enhancing efficiency. Automation in production lines is anticipated to improve consistency and lower labor costs. According to a study from the Manufacturing Institute, nearly 80% of manufacturers report an increase in productivity through the adoption of digital tools, indicating that these innovations will soon become standard practice in metal spinning operations. As industrial applications expand, the focus will continue to shift towards integrating smart manufacturing trends and sustainable practices, reflecting broader industry changes committed to environmental responsibility and efficiency.