Leave Your Message

The field of metal forming techniques has witnessed significant advancements in recent years, and among these, "Tube Spinning" is emerging as a frontrunner. A process that allows for the efficient shaping of tubular metal components, tube spinning is increasingly recognized for its minimal waste production and high structural integrity. According to a recent report by Grand View Research, the global metal forming market is expected to reach USD 272.03 billion by 2028, with tube spinning playing a pivotal role in this growth due to its versatility across various industries, such as aerospace, automotive, and construction.

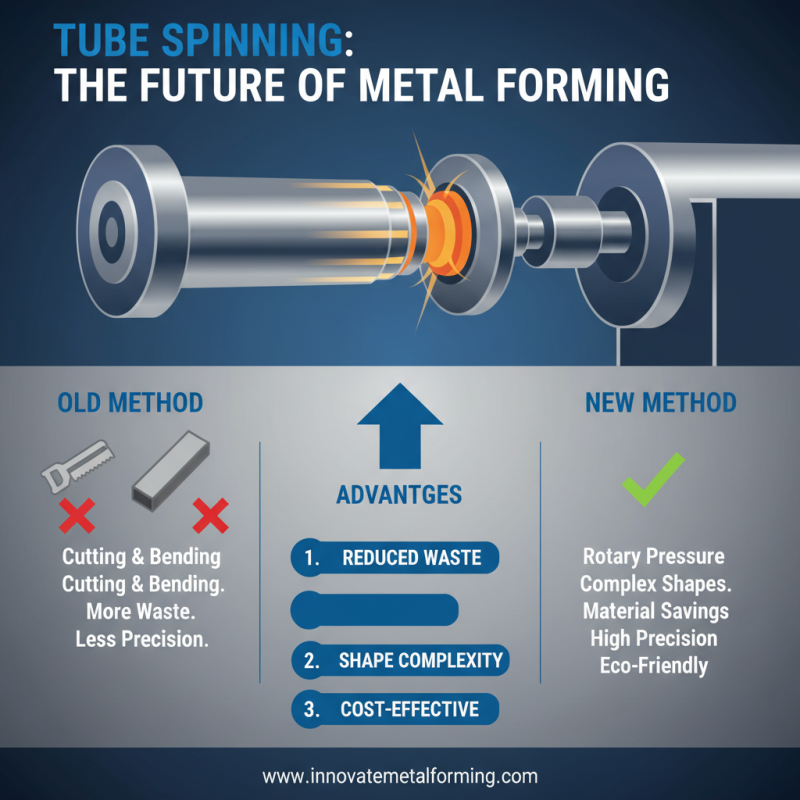

Tube spinning offers distinct advantages over traditional metal forming methods. Unlike techniques that require extensive machining or welding, tube spinning enables manufacturers to create complex shapes and sizes with precision, while maintaining the strength and durability of the material. As industries strive to adopt more sustainable manufacturing practices, the low-energy consumption and reduced material waste associated with tube spinning make it a compelling choice. The increasing scrutiny on environmental impacts and the demand for efficiency will further propel tube spinning to the forefront of metal forming solutions, facilitating innovative applications and designs that were previously unattainable.

Tube spinning is increasingly recognized for its advantages over traditional metal forming methods, particularly in its ability to produce complex shapes with exceptional precision. Unlike conventional techniques that rely heavily on cutting or bending, tube spinning shapes metal by rotating a tube on a lathe while applying pressure through various tools. This process eliminates the need for extensive machining, leading to significant material savings and reduced waste, which is beneficial both economically and environmentally.

Furthermore, tube spinning allows for superior mechanical properties in the final product. The continuous forming action not only improves the material's strength but also enhances its surface finish. This method is particularly advantageous for industries requiring lightweight, strong components, such as aerospace and automotive sectors. Additionally, the flexibility of tube spinning in accommodating various materials—ranging from standard metals to specialized alloys—makes it a versatile choice for manufacturers looking to innovate without the limitations imposed by traditional forming techniques.

Tube spinning, a versatile metal forming process, is increasingly being recognized for its applications across various industries. One of the key areas where tube spinning shines is in the aerospace sector, where lightweight yet durable components are critical. For aircraft manufacturing, tube spinning allows for the creation of complex shapes, such as framework structures and energy-efficient components, which contribute to the overall reduction of weight. This technique not only enhances fuel efficiency but also improves the aerodynamics of aircraft, making it a preferred choice among manufacturers.

Additionally, the automotive industry leverages tube spinning for producing parts like exhaust systems and structural components. The process enables manufacturers to create precise and robust components that meet the stringent safety and performance standards required in modern vehicles. Moreover, tube spinning is beneficial in the production of custom and short-run parts, providing flexibility that is often needed in automotive design and manufacturing. With its increasing utilization, tube spinning is set to revolutionize how various industries approach metal forming, delivering efficiencies and innovations that would have been unattainable with traditional methods.

The landscape of metal forming techniques is experiencing a transformation, with tube spinning technology at the forefront of this evolution. This process, which involves rotating a tube while applying pressure to shape it, has seen remarkable technical innovations that enhance precision, efficiency, and versatility. Modern advancements in computer numerical control (CNC) systems allow for greater accuracy and repeatability in tube spinning, enabling manufacturers to produce complex geometries that were previously unattainable. Moreover, the integration of real-time data analytics is optimizing production processes, reducing waste, and improving overall operational efficiency.

Tips: When considering tube spinning technology for your manufacturing needs, it’s essential to evaluate the compatibility of your existing equipment with CNC integration. Investing in the right software can significantly enhance your capabilities and streamline productivity.

Another critical innovation driving tube spinning forward is the development of advanced materials and alloys. These materials not only improve the strength and durability of the finished products but also reduce weight, a crucial factor in industries such as aerospace and automotive. As research into new metal composites continues, tube spinning is poised to expand its application range, making it an ideal choice for manufacturers looking to balance performance and sustainability.

Tips: Stay abreast of material trends in your industry. The right choice of materials can elevate the quality and performance of your products while also meeting regulatory standards for environmental sustainability.

| Technique | Advantages | Applications | Innovations |

|---|---|---|---|

| Tube Spinning | High precision, minimal waste, versatile shapes | Automotive, aerospace, medical devices | Advanced CNC technology, automation, smart sensors |

| Hydroforming | Complex shapes, uniform material distribution | Automotive panels, structural components | Software integration, real-time monitoring |

| Stamping | High volume production, low cost per unit | Sheet metal parts, enclosures | Electric press machines, adaptive stamping |

| Roll Forming | Continuous process, cost-effective for long parts | Construction, furniture | Robotic integration, improved tooling |

In recent years, the metal forming sector has experienced significant growth, with tube spinning emerging as a key technique driving this expansion. The demand for lightweight, durable components across various industries, such as aerospace, automotive, and construction, has prompted manufacturers to adopt innovative metal forming methods.

Recent market studies indicate that the tube spinning market is expected to witness a compound annual growth rate (CAGR) of over 5% through the next decade. This growth is attributed to the increasing need for precision-engineered parts that offer superior performance characteristics.

The rising focus on energy efficiency and sustainability also contributes to the positive trajectory of the tube spinning market. As industries strive for more environmentally friendly production processes, tube spinning presents an appealing option due to its minimal waste generation and ability to recycle materials effectively. Additionally, advancements in technology are enhancing the capabilities of tube spinning equipment, leading to improved production speeds and reduced operational costs. As a result, companies are more likely to invest in this technique as part of their long-term metal forming strategies.

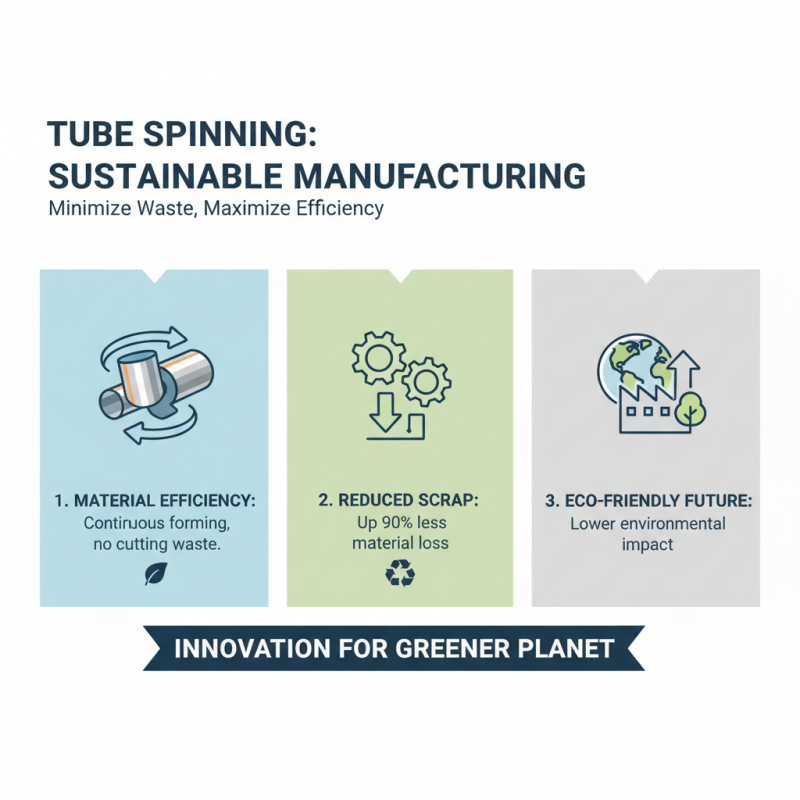

Tube spinning, as an innovative metal forming technique, offers significant environmental and sustainability benefits that position it as a vital process for the future of manufacturing. One of the primary advantages of tube spinning is its ability to minimize material waste. Unlike traditional methods that often involve cutting and machining, tube spinning utilizes a continuous tube of material, transforming it into desired shapes without extensive waste generation. This efficiency is not only economically beneficial but also aligns with the global shift toward sustainable manufacturing practices.

Furthermore, tube spinning requires less energy compared to other metal forming techniques. The process typically involves lower temperatures and reduced machinery operation times, leading to a decrease in the overall carbon footprint. By reducing energy consumption, tube spinning helps companies decrease their environmental impact while maintaining high production standards. This alignment with sustainability goals makes tube spinning an attractive option for manufacturers looking to improve their ecological footprint and contribute positively to the environment. As industries continue to embrace greener practices, tube spinning stands out as a forward-thinking solution that can drive both efficiency and sustainability in metal forming techniques.