Leave Your Message

The Head Flanging Machine is a vital tool in metalworking. It allows for the efficient shaping of metal edges. Understanding its operation can significantly enhance your projects.

Using this machine effectively requires practice and attention. One common mistake is not adjusting the settings correctly. Overworking the metal can lead to flaws, affecting the final quality.

With the right technique, the Head Flanging Machine thrives in many applications. It simplifies processes that would otherwise be tedious. However, users must regularly assess their approach. Continuous improvement in using this technology is crucial.

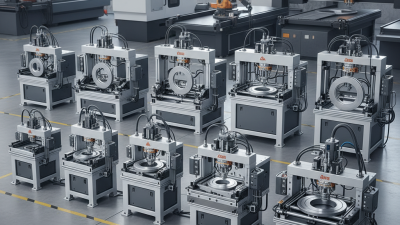

Head flanging machines are essential tools in metalworking. They help create flanges, which are used to connect metal parts securely. Understanding their operation is crucial for achieving precise results. A head flanging machine typically features a rotating tool that forms the metal edge into a desired shape. This process can be a bit tricky, and mastering it takes time.

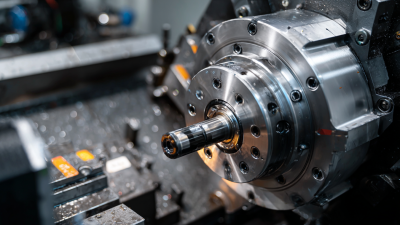

When using a head flanging machine, it's vital to pay attention to the material's thickness. Thinner metals can be prone to warping if not handled correctly. Conversely, thicker materials may require more force and can lead to tool wear. Users often find themselves adjusting the machine settings frequently. It's not unusual to encounter inconsistencies in the finish, prompting a reassessment of their technique. Observing these aspects leads to improvement over time.

Proper maintenance of the machine is often overlooked. Regular cleaning and lubrication can prevent issues down the line. Some operators might skip this step, resulting in reduced efficiency. This negligence highlights the need for continuous learning in metalworking. Experimenting with different settings can yield better techniques and enhance skill development. Each project offers a chance to refine one's approach, ensuring better final results.

This chart illustrates the expected efficiency of head flanging machines in metalworking from 2022 to 2026. A steady increase in efficiency is anticipated as technology and techniques improve in the upcoming years.

A head flanging machine is essential for many metalworking processes. Its key components include the flanging head, hydraulic system, and control panel. The flanging head performs the task of shaping metal edges. This part is vital. A well-designed flanging head improves the accuracy of the flanging process.

The hydraulic system provides the necessary power. It allows for precise control over the metal's deformation. Reports indicate that machines with advanced hydraulic features can increase efficiency by up to 30%. Many workshops still rely on outdated systems. This can lead to inefficiencies and safety concerns. Regular maintenance of these systems is crucial.

The control panel is where operators manage the machine. It should be user-friendly and intuitive to reduce errors. Even with advanced technology, human error remains a possibility. In a busy production environment, this can impact overall output. Training staff on proper usage remains essential. Inadequate training may result in costly mistakes. Keeping equipment updated and operators skilled is key to maximizing productivity.

| Component | Description | Material Compatibility | Typical Applications | Key Features |

|---|---|---|---|---|

| Main Frame | The structure that supports all other components and absorbs vibrations during operation. | Metal sheets, aluminum, steel | Automotive parts, HVAC components | Sturdy construction, vibration dampening |

| Flanging Head | The tool that performs the flanging process, shaping the edges of metal sheets. | Metal sheets, fiberglass | Ductwork, marine parts | Interchangeable tooling, precision control |

| Drive Mechanism | Provides power to the flanging head, enabling the movement and rotation necessary for flanging. | Various metals | Sheet metal fabrication, structural components | Variable speed control, high torque |

| Control System | Digital interface that allows for precise adjustments and monitoring of the flanging process. | Applicable to all compatible materials | General metalworking and flanging tasks | User-friendly display, programmable settings |

| Safety Features | Includes emergency stops, shields, and sensors to prevent accidents. | All types of metal sheets | Industrial environments, metal shops | Comprehensive safety system, compliance certifications |

Operating a head flanging machine can enhance efficiency in metalworking. To begin, ensure you wear appropriate safety gear. Check your tools and materials before starting. It's essential to prepare your workspace, keeping it organized and clutter-free. A clean area allows for better focus and reduces the risk of accidents.

Next, set the machine according to the specifications of your project. Adjust the flanging depth and speed carefully. This part requires attention. If settings are off, the quality of the flange will suffer. It’s common for new operators to underestimate this step. Many find themselves making adjustments during their first runs, which can be frustrating.

As you begin the flanging process, feed the metal gently into the machine. Observe the operation closely. If you hear unusual noises, stop immediately. It’s important to troubleshoot issues before they escalate. Remember, not every attempt will result in a perfect flange. Learning takes time, and each mistake offers a lesson. Seeking feedback from experienced operators can also help improve your skills.

When using a head flanging machine, safety should be a top priority. Always wear protective goggles and gloves. These items shield against flying metal shavings and sharp edges. It is crucial to avoid loose clothing. Dangling fabric can easily get caught in machinery, leading to serious injury. Hearing protection is also recommended, as machines can produce loud noises.

Before starting, inspect the machine for any signs of wear or damage. Identifying issues beforehand can prevent accidents. Ensure that all safety guards are in place. If something doesn't feel right, stop immediately. Maintenance is a key factor that sometimes gets overlooked. A well-maintained machine is safer and operates more efficiently.

Never operate the machine when fatigued or under the influence. Your focus is essential. Communicate clearly with team members. If you are unsure how to use the machine correctly, seek help. Ignoring safety procedures can lead to mistakes. Regularly review safety protocols with the team. It's a simple way to keep everyone informed.

Troubleshooting a head flanging machine requires attention to detail. Users often encounter issues like uneven flanges or misalignment. These problems can lead to wasted materials and time. Regularly check your machine’s setup. Ensure that the workpiece is securely clamped and that the tool height is correctly adjusted. Small mistakes can result in significant flaws.

Another common issue is tool wear. Dull tools can cause poor cuts and jagged edges. Regularly inspect your flanging tools for signs of wear. Replacing worn tools promptly can enhance performance. If the machine vibrates during operation, it may indicate alignment problems. Tighten all bolts and ensure proper alignment to minimize disruptions.

Keeping a maintenance log helps track recurring issues. This record can guide adjustments and future repairs.

Lighting in the workspace is also crucial. Insufficient light can hide problems until it's too late. Consider adding LED lights for better visibility. Keeping your work area tidy can prevent accidents and improve focus. Remember to clean debris regularly. Sometimes, simple habits lead to more efficient metalworking.