0102030405

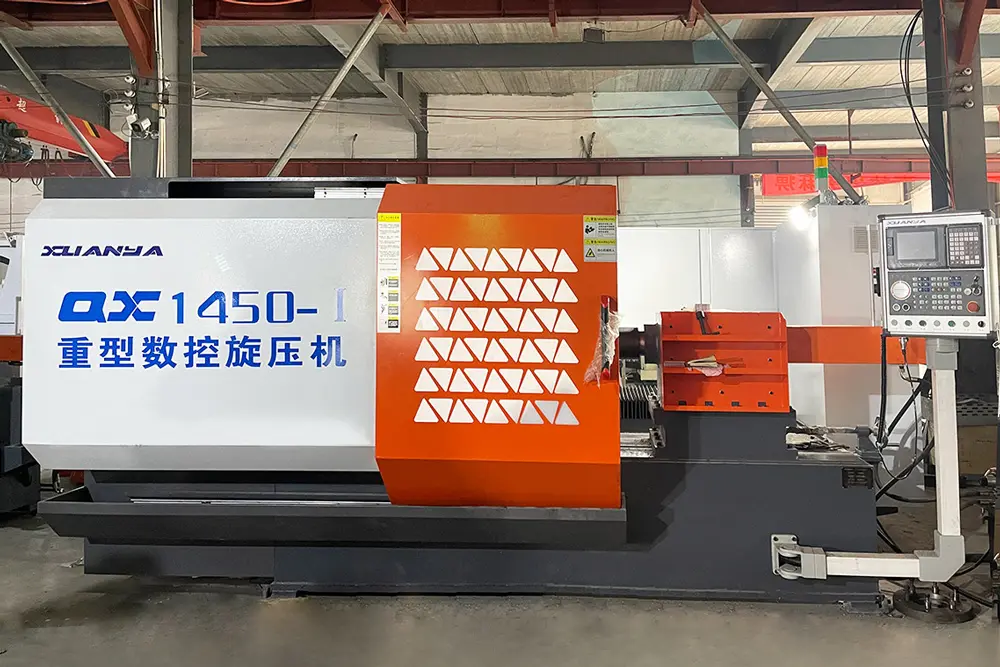

CNC Hot Heat Pipe Spinning Machine For Gas Fire Extinguisher Cylinder Bottom End Shrinking

Product Description

-

-

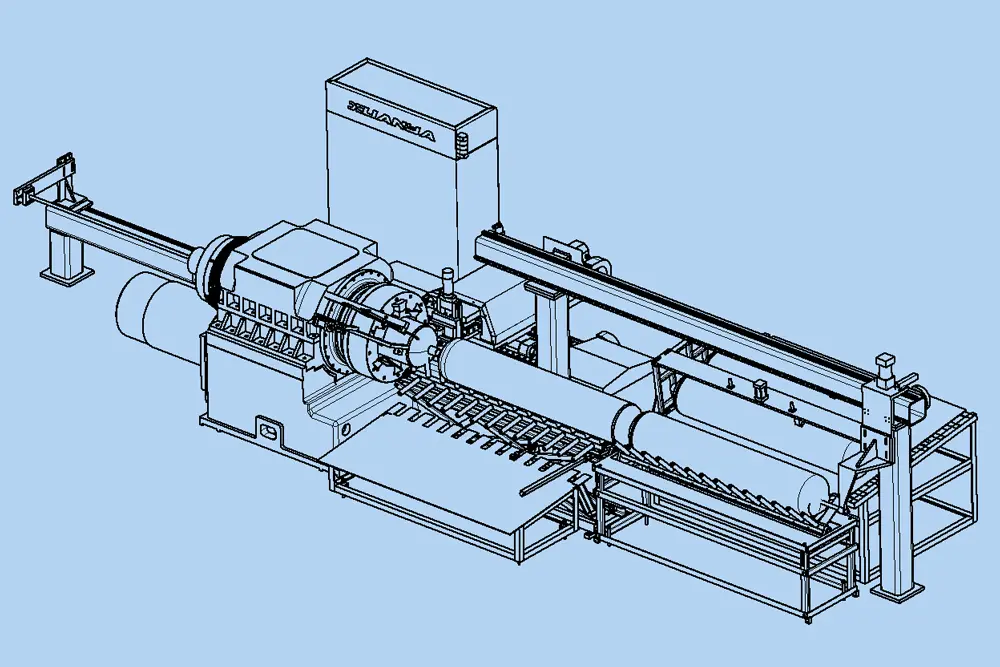

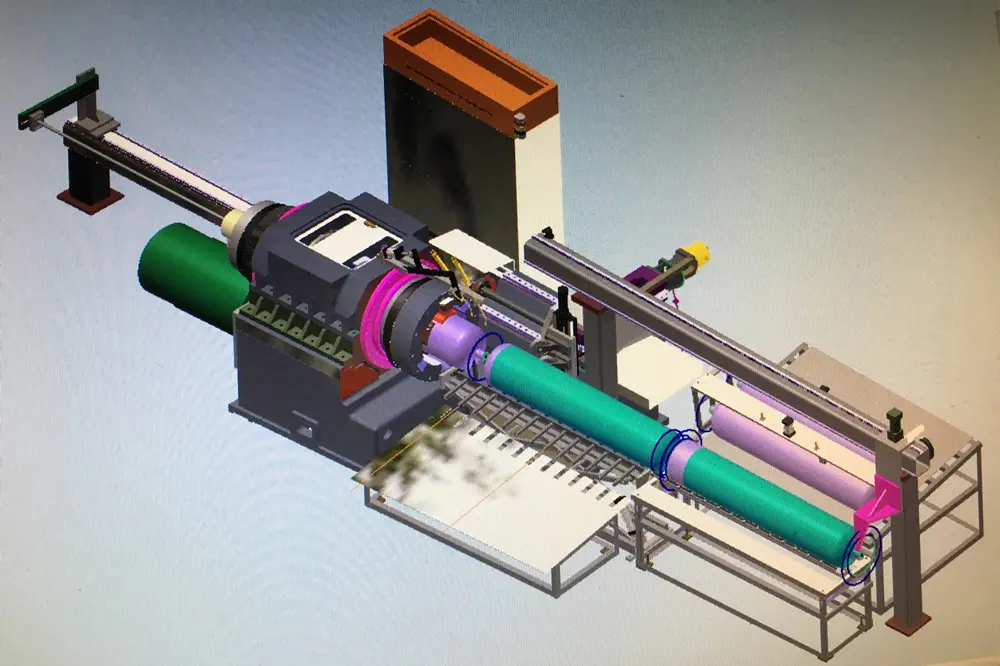

A standout feature of this equipment is its rotary cylinder, which is equipped with a tie rod chuck that simplifies the loading and unloading of materials. This chuck design ensures smooth and efficient material handling, thereby minimizing downtime during the production process. Additionally, the clamping force of the chuck can be easily adjusted by the operator, providing enhanced control and flexibility during operations. This adjustability allows the equipment to handle a wide range of material types and sizes with precision and reliability.Another notable feature is the self-developed box-type turret, engineered to maintain stability and consistent performance even under high temperatures and significant forces. This turret is particularly well-suited for demanding production conditions. Its unique design allows for closing without the need for a core mold, which reduces setup times and streamlines the overall production process. For applications requiring greater precision, a core mold can be incorporated, enabling more accurate and efficient closing operations. This flexibility allows manufacturers to effectively thicken and close designated areas, accommodating a variety of production needs.

This advanced equipment is widely utilized across several industries, including the production of hydraulic cylinders, LNG high-pressure gas cylinders, military projectiles, pressure vessels, and other specialized components. Its robust and adaptable design makes it invaluable for manufacturers aiming to enhance production efficiency while maintaining the highest quality standards. The combination of modularity, user-friendly features, and versatility positions this equipment as a critical tool in modern manufacturing environments, helping companies remain competitive in an increasingly demanding market.

Product parameters

|

Item |

Parameter |

||

|

Model |

SX-250 |

SX-350 |

SX-500 |

|

Control System |

CNC |

||

|

Motor |

Digital AC Servo Motor |

||

|

Maximum blank diameter |

200-250 mm |

250-350 mm |

250-500 mm |

|

Spindle speed change |

Servo stepless speed change |

||

|

X/Z axis pulse equivalent |

0.001mm |

||

|

Positioning accuracy |

0.01mm |

||

|

Repeatability |

0.02 mm |

||

|

Thickness (Stainless steel) |

3-5mm |

4-6mm |

5-8mm |

|

Spinning lubrication |

Automatic spray lubrication |

||

|

Stroke protection |

Have |

||

|

Number of spindle gears |

Infinitely variable speed |

||

|

Hand wheel |

Have |

||

|

Machine tool lubrication |

Centralized automatic refueling |

||