0102030405

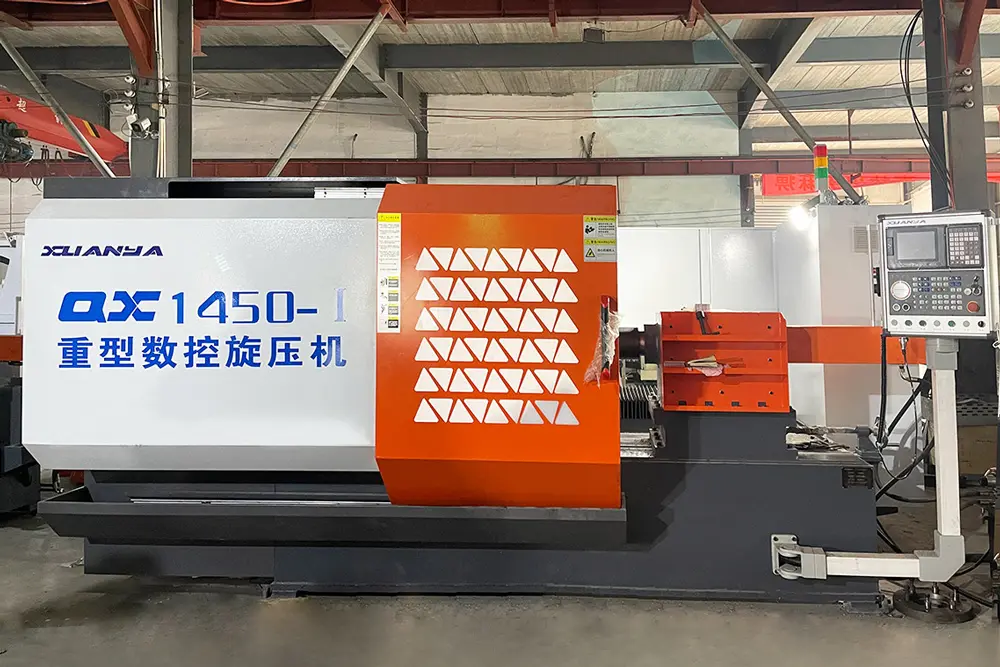

CNC Sheet Metal Spinning Machine For Kitchenware And Conical Containers

Product Description

The operation of the machine, including its movement and auxiliary functions, is entirely governed by advanced CNC programming. This ensures that every operation is executed with high accuracy and repeatability, which is crucial for maintaining quality standards. Additionally, the machine is designed with a comprehensive internal and external safety protection structure, making it not only efficient but also safe for operators. Its outstanding processing performance and operational efficiency provide a solid foundation for high-efficiency production across various sectors.

Beyond its primary function of thinning thick metal plates, the CNC double-wheel thinning spinning machine is also highly versatile, making it suitable for small-scale spinning operations. It excels in producing precision components such as automotive parts, aerospace components, and household utensils. Its compact design and robust construction are particularly advantageous for workshops with limited space, while its efficiency facilitates rapid production cycles. This machine is especially beneficial for industries that demand high-precision metal forming, including electronics, medical devices, and energy equipment.

To ensure long-term reliability and optimal performance, regular maintenance is essential. This includes routine lubrication and thorough inspections of the CNC system. The machine's capability to handle a diverse range of materials—such as carbon steel, stainless steel, and non-ferrous metals like aluminum and copper—positions it as a transformative solution for both large-scale industrial applications and specialized small-scale production. The development of the CNC double-wheel thinning spinning machine represents a significant advancement in metal spinning technology, delivering unparalleled efficiency and precision that meets the demands of modern manufacturing.

Product parameters

|

Item |

Parameter |

||

|

Model |

PX-250Ⅰ |

QX-150Ⅱ |

|

|

Maximum sheet diameter |

250mm |

50-150mm |

|

|

Diameter of over-drag plate |

200mm |

-- |

|

|

Main motor power |

5.5kw |

11kw |

|

|

Spindle speed |

3500Rpm |

800Rpm |

|

|

Stroke |

X-axis |

300mm |

-- |

|

Z-axis |

350mm |

-- |

|

|

Maximum tail force |

7kn |

-- |

|

|

Tail stroke |

300mm |

300mm |

|

|

Processing material thickness |

Copper/aluminum |

0.5-2.0mm |

-- |

|

Steel |

0.5-1.2mm |

-- |

|

|

Stainless steel |

0.5-0.8mm |

-- |

|

|

Tool holder station |

4+1 |

1+1 |

|

|

Whip blank support plate travel |

300mm |

300mm |

|

|

Positioning accuracy |

0.01mm |

0.01mm |

|