0102030405

Customizable CNC Large Diameter Plate Spinning Machine For Auto & Aerospace Parts

Product Description

-

-

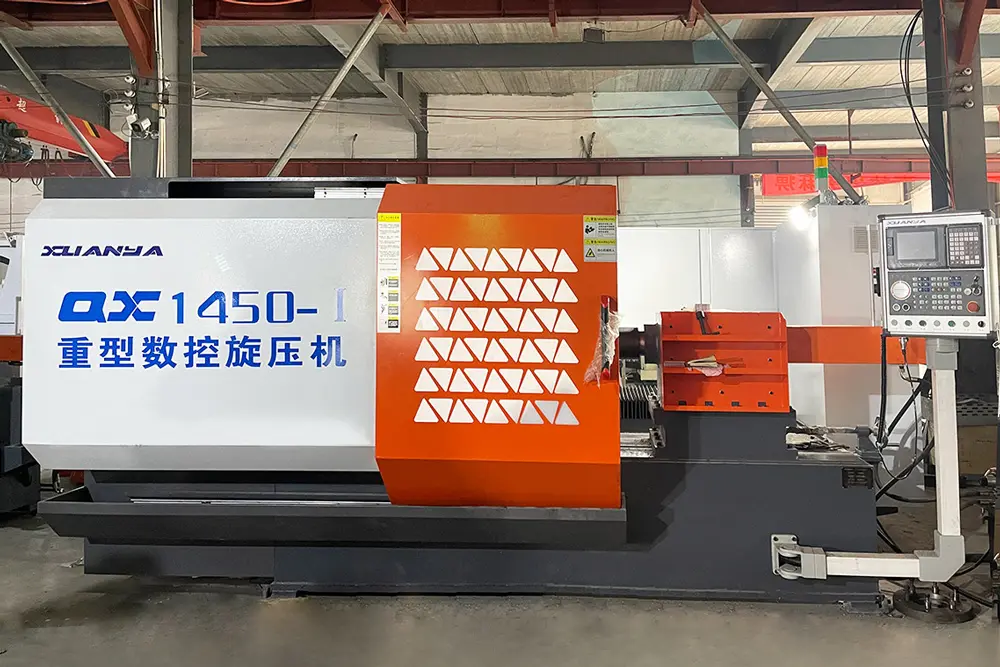

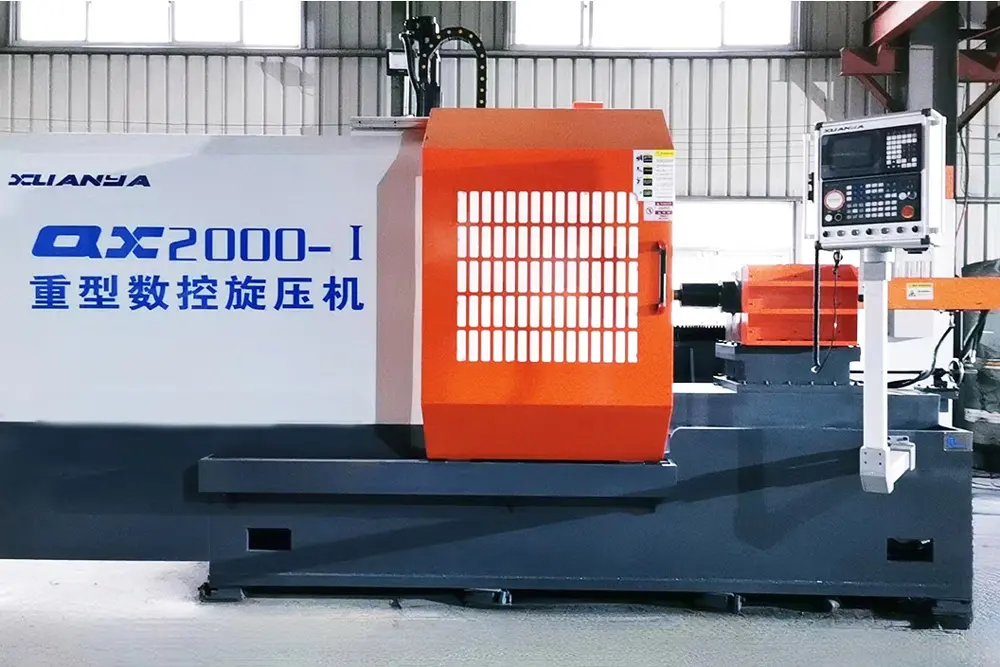

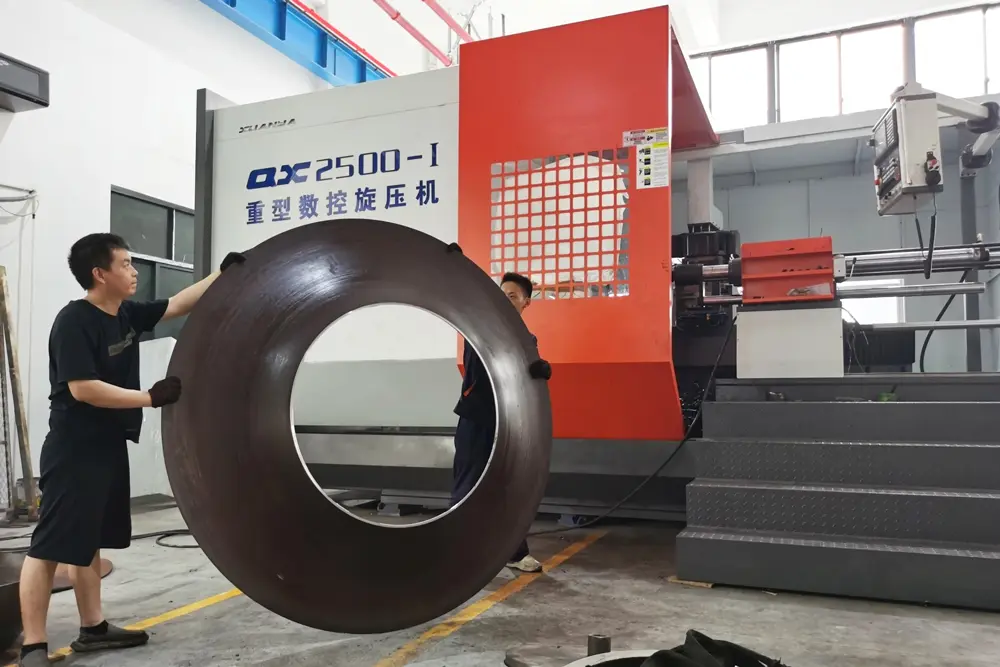

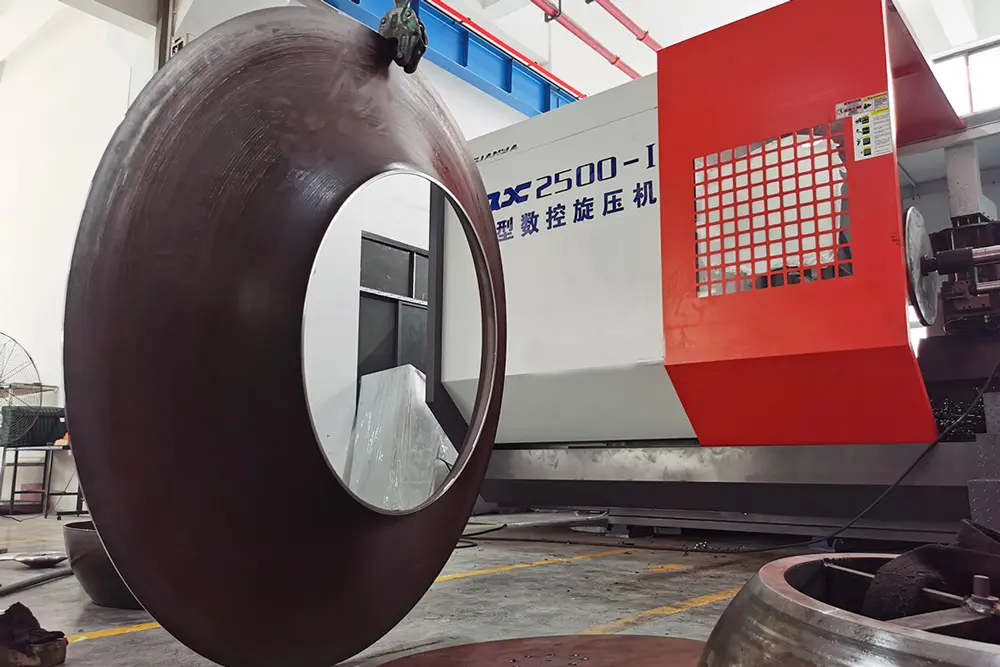

These machines are distinguished by their ability to support a diverse array of processing technologies, allowing manufacturers to produce various shapes and specifications with ease. The advanced design of the 1450, 1650, 2000, and 2500 series enables them to deliver high-performance results, particularly in the production of parts with intricate geometries, uniform wall thicknesses, and smooth surface finishes. This capability makes them ideal for industries that require precision metal forming, including the creation of deep containers, long cylinders, and more complex shapes.Their robust capabilities make them applicable across a wide range of industries. In the **kitchenware** sector, they are utilized to manufacture large cooking pots, pans, and other metal utensils. In the **musical instrument** industry, these machines excel at producing components such as brass wind instruments, where surface smoothness and consistency are critical. The **automotive industry** benefits from their ability to create high-precision components, including wheels, rims, and engine parts. Additionally, the **aerospace sector** relies on these machines to produce lightweight yet durable components that demand the highest levels of precision.

Moreover, the flexibility in processing options provided by the 1450, 1650, 2000, and 2500 series allows users to easily adapt to varying production requirements, optimizing the machines for different materials and part configurations. This versatility enables manufacturers to streamline their production processes, enhance efficiency, and maintain the highest quality standards. Whether for small-scale production runs or large-volume manufacturing, these CNC spinning machines offer a reliable and efficient solution to meet the diverse needs of today’s industrial sectors.

Product parameters

|

Item |

Parameter |

||||

|

Model |

QX1450-Ⅰ |

QX1650-Ⅰ |

QX2000-Ⅰ |

QX2500 |

|

|

Maximum sheet diameter |

1450mm |

1650mm |

2000mm |

2500mm |

|

|

Diameter of over-drag plate |

500mm |

500mm |

1800mm |

800mm |

|

|

Main motor power |

45kw |

75kw |

110kw |

130kw |

|

|

Spindle speed |

900Rpm |

750Rpm |

600Rpm |

600Rpm |

|

|

Stroke |

X-axis |

1450mm |

1650mm |

2000mm |

2500mm |

|

Z-axis |

1000mm |

800mm |

1000mm |

1200mm |

|

|

Maximum tail force |

25kn |

50kn |

75kn |

100kn |

|

|

Tail stroke |

500mm |

600mm |

800mm |

1000mm |

|

|

Processing material thickness |

Copper/aluminum |

1.0-10.0mm |

1.0-8.0mm |

1.0-10mm |

1.0-15.0mm |

|

Steel |

1.0-5.0mm |

1.0-6.0mm |

1.0-6.0mm |

1.0-12.0mm |

|

|

Stainless steel |

1.0-3.0mm |

1.0-4.0mm |

1.0-4.0mm |

1.0-10.0mm |

|

|

Special hydraulic tool magazine |

Four stations |

||||

|

Automatic trimming and forming mechanism |

Optional |

||||

|

Automatic trimming and forming mechanism |

Optional |

||||