0102030405

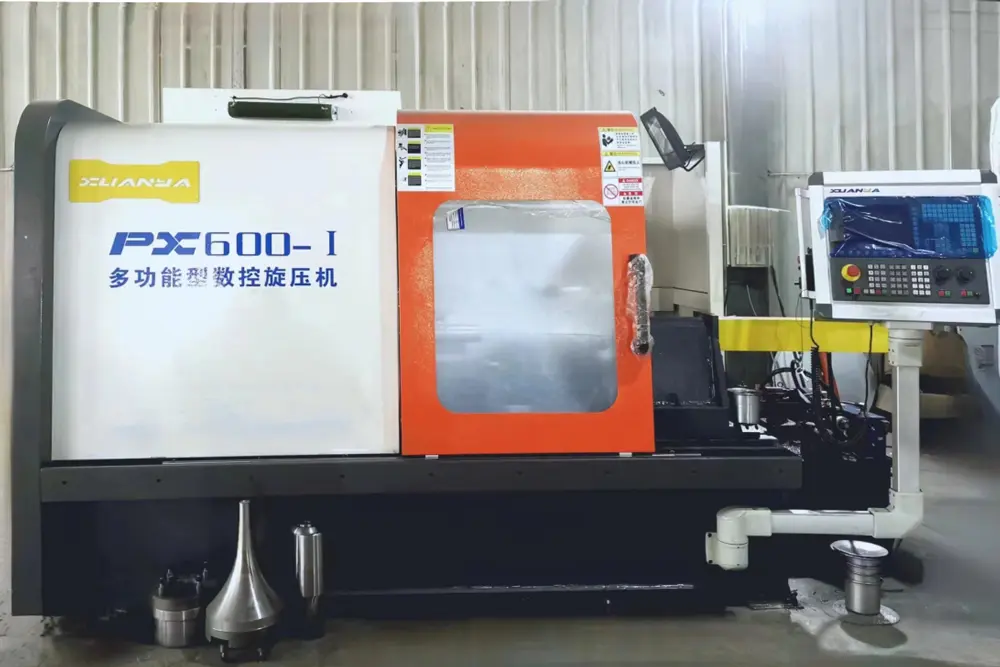

Multifunctional CNC Metal Spinning Machine For Precision Metal Cone and Disc Manufacturing

Product Description

The standout features of the PX600-I is its exceptional processing accuracy and stability. This machine can adeptly perform complex tasks such as deep drawing and rotational molding, ensuring that it meets a wide range of process requirements. The ability to execute these intricate operations with precision makes the PX600-I a valuable asset for manufacturers who demand high-quality results.

The design of the PX600 is compact, which not only allows for efficient spinning of medium-sized workpieces but also optimizes the use of workshop space. This is particularly advantageous in production environments where space is limited, as it enables manufacturers to maximize their operational efficiency without compromising on performance.

Additionally, the PX600 is equipped with an automatic feeding system and advanced automatic control functions. These features facilitate unmanned production, significantly enhancing production efficiency while reducing the need for manual intervention. This automation not only streamlines the manufacturing process but also minimizes the risk of human error, contributing to overall product quality.

Safety and ease of operation are also key considerations in the design of the PX600-I. The machine is built to be user-friendly, ensuring that operators can work with it safely and reliably. Whether the task involves high-precision parts processing or accommodating diverse process requirements, the PX600-I stands out as an ideal choice for manufacturers seeking high cost performance in modern manufacturing environments. Its combination of advanced technology, efficiency, and versatility makes it a leading solution for today’s production challenges.

Product parameters

|

Item |

Parameter |

||

|

Model |

PX600-Ⅰ |

QX600-Ⅱ |

|

|

Maximum sheet diameter |

600mm |

||

|

Diameter of over-drag plate |

400mm |

||

|

Main motor power |

11kw |

||

|

Spindle speed |

2500Rpm |

||

|

Stroke |

X-axis |

600mm |

|

|

Z-axis |

500mm |

||

|

Maximum tail force |

10kn |

||

|

Tail stroke |

500mm |

||

|

Processing material thickness |

Copper/aluminum |

0.5-3.5mm |

|

|

Steel |

0.5-2.0mm |

||

|

Stainless steel |

0.5-1.5mm |

||

|

Tool holder station |

4/6/8 |

||

|

Whip blank support plate travel |

300mm |

||

|

Positioning accuracy |

0.01mm |

||